High-toughness wear-resistant shield tunneling machine inserted hob cutter ring and preparation method thereof

A technology of shield machine and cutter ring, which is applied in the direction of additive manufacturing, mining equipment, earth drilling and mining, etc., can solve the problems of single shape of cutter teeth, poor toughness of cutter teeth, low bonding strength, etc., and achieve fine grain structure and reduce Production cost and the effect of improving the performance of the cutter tooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

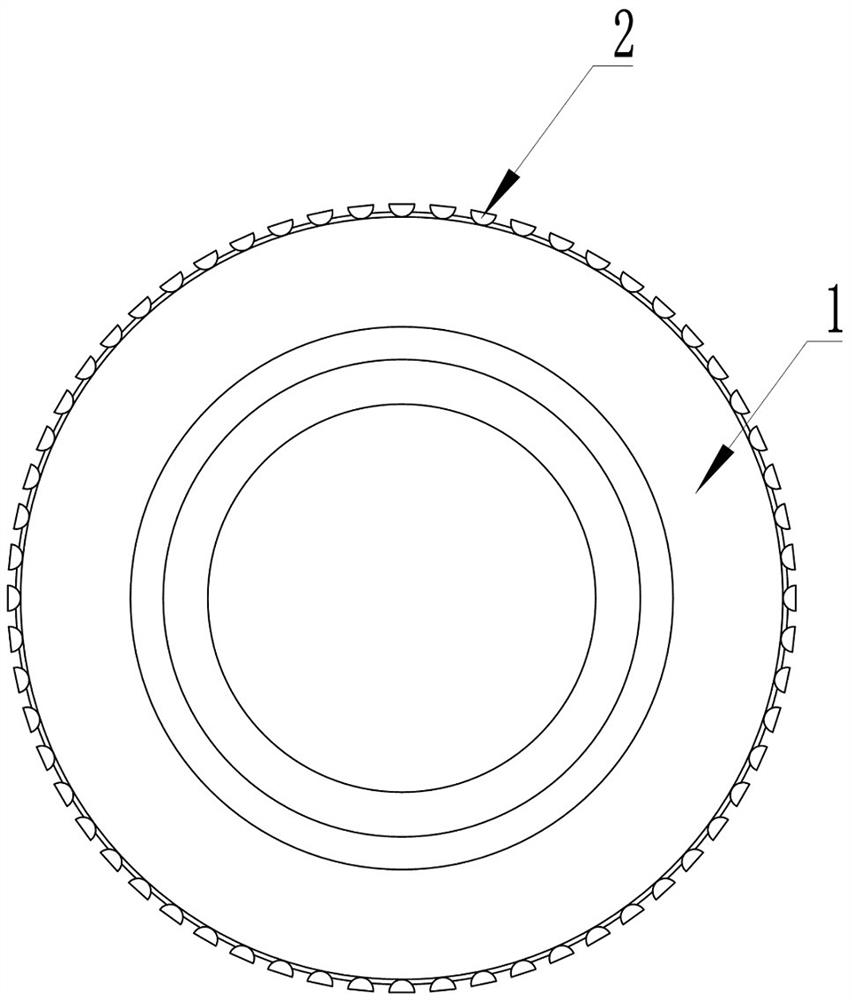

[0036] A high-toughness wear-resistant shield machine insert hob cutter ring, such as figure 1As shown, it includes the cutter ring base 1 and the cutter teeth 2, the cutter teeth 2 are located on the outer circumferential surface of the cutter ring base 1, the combination of the cutter ring base 1 and the cutter teeth 2 is metallurgical bonding, and the cutter teeth 2 are printed on the The cutter ring substrate 1 is printed layer by layer, and the overall tempering heat treatment of the cutter ring substrate 1 and the cutter teeth 2 is performed. In this embodiment, firstly, the cutter teeth 2 are printed layer by layer on the pre-prepared cutter ring base 1 through the 3D printing process. The tooth 2 produced by using the 3D printing process has the characteristics of short high temperature residence time and fast cooling speed. The structure and grain of the tooth 2 are finer, the performance is better, and the occurrence of component segregation can be avoided, which can...

Embodiment 2

[0040] A method for preparing a high-toughness wear-resistant shield machine insert hob cutter ring, comprising the following steps:

[0041] S1. Prepare the cutter ring base 1 of the insert hob cutter ring. Specifically, the specific operation steps of step S1 include: Y1, the raw materials for configuring the knife ring base 1 are smelted in an electric furnace, refined outside the furnace, vacuum degassing treatment and gas shielded electroslag remelting treatment to obtain a steel ingot. In this embodiment, the mass percentages of the raw materials in the cutter ring base 1 are 0.43-0.65% for C, 0.80-1.3% for Si, 0.42-0.65% for Mn, 4.3-6.0% for Cr, and 1.10% for Mo. -1.80%, V is 0.6-1.5%, impurity S≤0.02%, impurity P≤0.02%, Fe balance, under high wear, strong extrusion and high impact working environment, the knife ring base is manufactured under the above composition ratio 1 overall hardness>HRC53, impact toughness>15J / cm 2 , can effectively meet the needs of use, and e...

Embodiment 3

[0051] A high-toughness wear-resistant shield machine insert hob cutter ring, such as figure 1 As shown, it includes a knife ring base 1 and a knife tooth 2. The knife tooth 2 is located on the outer circumferential surface of the knife ring base 1. It is characterized in that the combination of the knife ring base 1 and the knife tooth 2 is metallurgical bonding, and the knife tooth 2 passes through The 3D printing process prints layer by layer on the knife ring base 1 and performs the overall tempering heat treatment of the knife ring base 1 and the cutter teeth 2 . In this embodiment, firstly, the cutter tooth 2 is printed layer by layer on the pre-prepared cutter ring substrate through the 3D printing process. The cutter tooth 2 and the cutter ring substrate 1 are metallurgically bonded, and the bonding strength is high. The 3D printing process has the characteristics of short residence time at high temperature and fast cooling speed. The structure and grain of the knife t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com