A method for preparing nickel-copper sulfur and oxygen compound composite film electrodes

A composite thin film and oxygen compound technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of difficult to manufacture supercapacitors with large capacitance, decrease in electrode specific capacitance, and low active material content, and achieve Low cost, low electrode internal resistance, and low corrosion resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

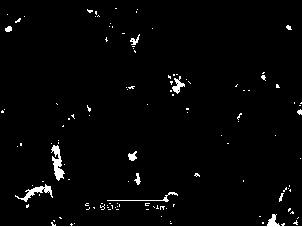

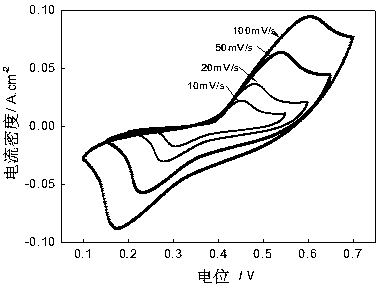

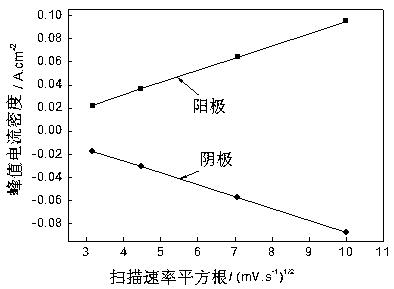

[0024] A low-temperature sulfur oxidation cycle treatment method for preparing nickel-copper sulfur-oxygen compound composite thin film electrodes. Firstly, pure iron foil is used as the base material, and the current collector base with a size of 20 mm×10 mm×0.2 mm is degreased, washed with water, Pickling, washing with water, and then electroless plating in an alkaline nickel-copper-phosphorus plating solution at (82±1)°C for 30 minutes to prepare a current collector with a nickel-copper-phosphorus alloy coating on the surface. EDS analysis showed that the mass fractions of nickel, copper and phosphorus in the nickel-copper-phosphorus alloy coating were 47.08%, 46.57% and 6.35%, respectively. After washing and drying the current collector, soak it in supersaturated sodium sulfide solution for 1 minute, take it out and hang it on the bracket, and put it into an oven that has been heated to 190°C for low-temperature sulfur oxidation treatment for 1 hour; take it out and cool it...

Embodiment 2

[0029] The same method as in Example 1 was used to prepare nickel-copper sulfur and oxide compound thin film electrodes, the difference being that the current collector substrate was copper foil, and after pretreatment, the treatment time of the electroless plating was 120 minutes; The sulfide solution covered is supersaturated potassium sulfide, and the soaking time is 2 minutes; the low-temperature sulfur oxidation cycle treatment temperature is 170°C, the cycle treatment time is 0.5 hour, and the cycle treatment is 4 times.

Embodiment 3

[0031] The same method as in Example 1 was used to prepare nickel-copper sulfur and oxygen compound composite film electrodes, the difference being that the current collector substrate was nickel foam, and after pretreatment, the treatment time of the electroless plating was 80 minutes; The sulfide solution covered is supersaturated ammonium sulfide, and the soaking time is 1 minute; the low-temperature sulfur oxidation cycle treatment temperature is 220°C, the cycle treatment time is 1 hour, and the cycle treatment is done twice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com