Antibacterial and anticrease fabric

A wrinkle-resistant fabric and fabric technology, applied in protective clothing, clothing, special outerwear, etc., can solve the problems of fabric limitation, time-consuming, fabric deformation, etc., and achieve the effect of preventing bacteria, wide application, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

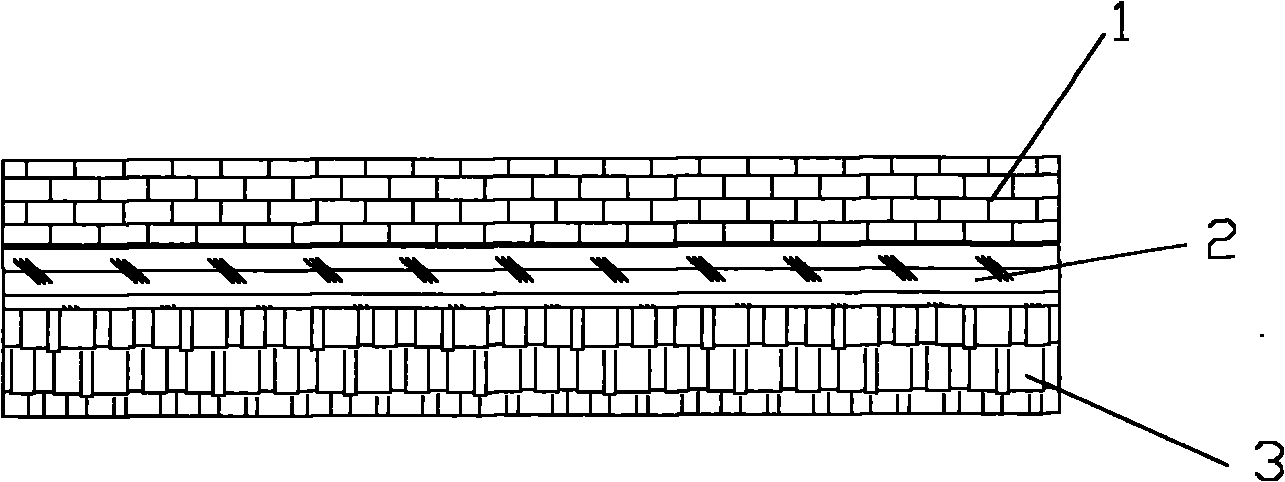

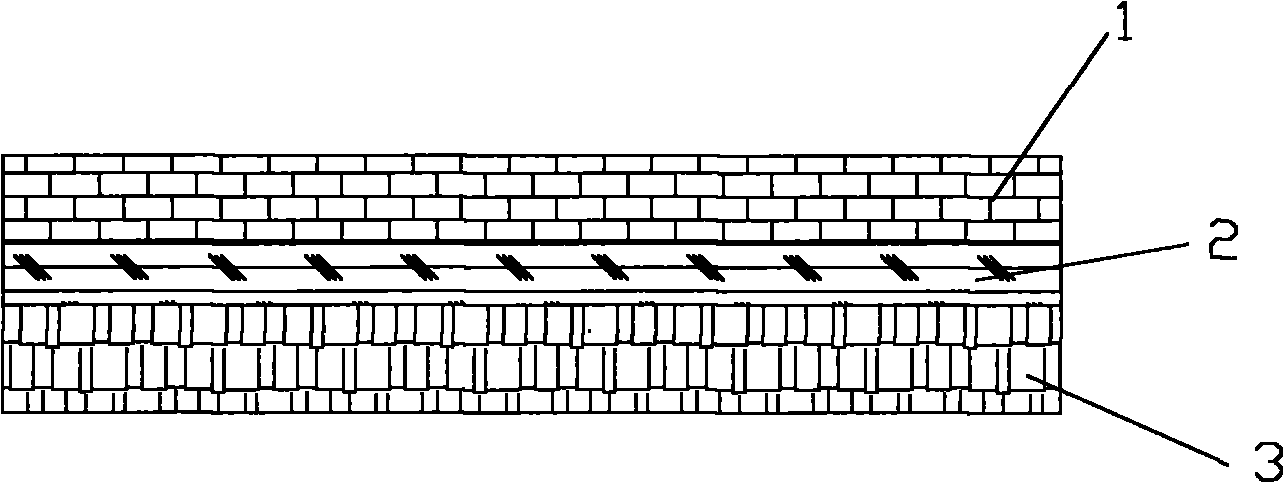

Image

Examples

Embodiment 1

[0016] The specific preparation process of the fabric is as follows:

[0017] a) Prepare an antibacterial layer, each component and percentage in the antibacterial layer are: 20% of nano-bamboo charcoal fiber, 40% of natural cotton, and 40% of polyester;

[0018] Concrete preparation process is as follows:

[0019] 1) First, the nano-bamboo charcoal fiber and polyester are made into blended yarn lines through the processes of cleaning, opening, drawing, roving, spinning, and winding;

[0020] 2) Then, the natural cotton is made into natural cotton strands through the processes of cleaning, opening, drawing, roving, spun yarn, winding, and twisting;

[0021] 3) Finally, use the prepared blended yarn as the warp and the natural cotton strand as the weft, and make the antibacterial layer fabric through the weaving process.

[0022] b) Prepare the anti-wrinkle layer. The material of the anti-wrinkle layer is selected from the memory type polyurethane material, add an appropriate...

Embodiment 2

[0026] The specific preparation process of the fabric is as follows:

[0027] a) Prepare an antibacterial layer, each component and percentage in the antibacterial layer are: 25% of nano-bamboo charcoal fiber, 45% of natural cotton, and 30% of polyester;

[0028] Concrete preparation process is as follows:

[0029] 1) First, the nano-bamboo charcoal fiber and polyester are made into blended yarn lines through the processes of cleaning, opening, drawing, roving, spinning, and winding;

[0030] 2) Then, the natural cotton is made into natural cotton strands through the processes of cleaning, opening, drawing, roving, spun yarn, winding, and twisting;

[0031] 3) Finally, use the prepared blended yarn as the warp and the natural cotton strand as the weft, and make the antibacterial layer fabric through the weaving process.

[0032] b) Prepare the anti-wrinkle layer. The material of the anti-wrinkle layer is selected from the memory type polyurethane material, add an appropriate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com