Slag modifier for converter refining

A converter refining and slag-adjusting agent technology is applied in the field of steel-making and slag-making technology, which can solve the problems of poor ability of primary slag to absorb inclusions, improve the erosion ability of ladle refractories, and adversely affect the purity of molten steel, so as to reduce slag formation. time, improving the quality of finished steel products, and the effect of improving the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

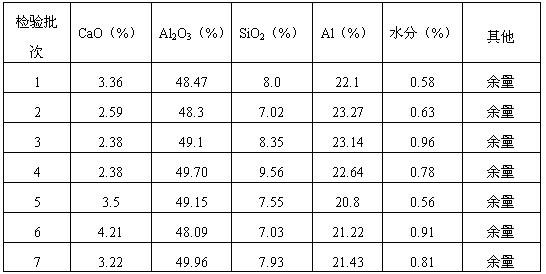

[0010] The slagging agent for converter refining, its composition mass percentage (%) is: CaO = 0 ~ 6.0, Al 2 o 3 = 48~58, SiO 2 =0~12, Al=20~25, and the balance is unavoidable impurities.

[0011] Preparation method: first grind the bauxite into powder and mix it with aluminum chips, then add an appropriate amount of ordinary binder and mix well, use a special machine to briquetting it into a ball, and then bake the briquette to reduce the briquette. The water content increases the strength of the briquette.

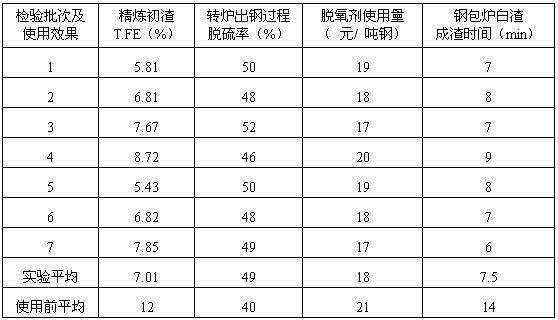

[0012] Specific usage method: put the slag adjusting agent into the high-level bunker on the top of the converter, add the alloy into the ladle through the feeding system during the tapping process, and form the primary refining slag in the ladle after tapping, enter the ladle refining furnace and press Adding lime and slagging agent in a certain proportion can quickly form refining slag with good fluidity and strong desulfurization ability. See Table 1 and Table 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com