Capacity loaded magnetic flux compression generator with stator coil operating sectionally

A stator coil and capacitive load technology, which is applied in blasting and other directions, can solve the problem of low frequency range of the signal spectrum, achieve the effect of increasing the frequency band, increasing the signal bandwidth, and increasing the signal frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

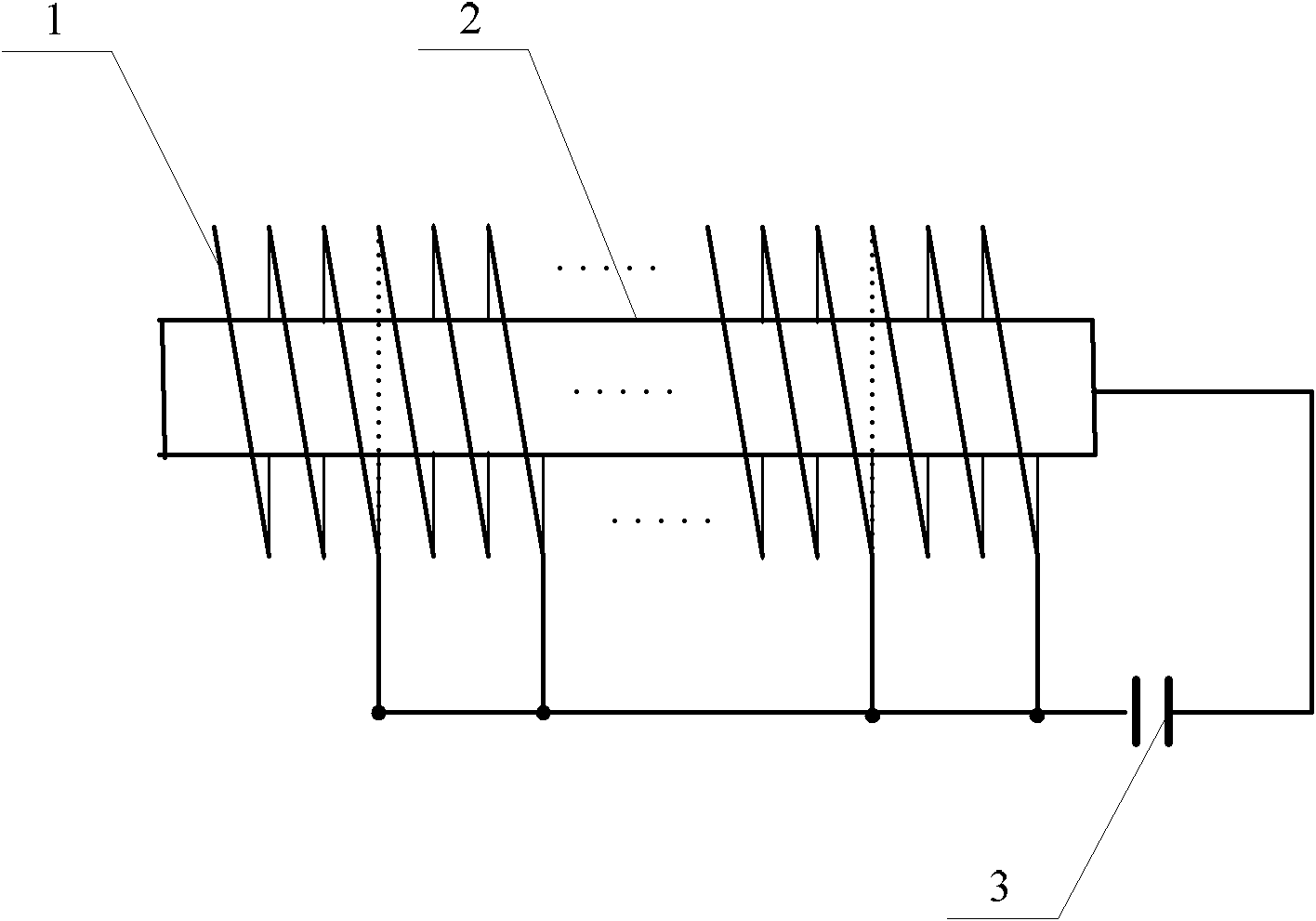

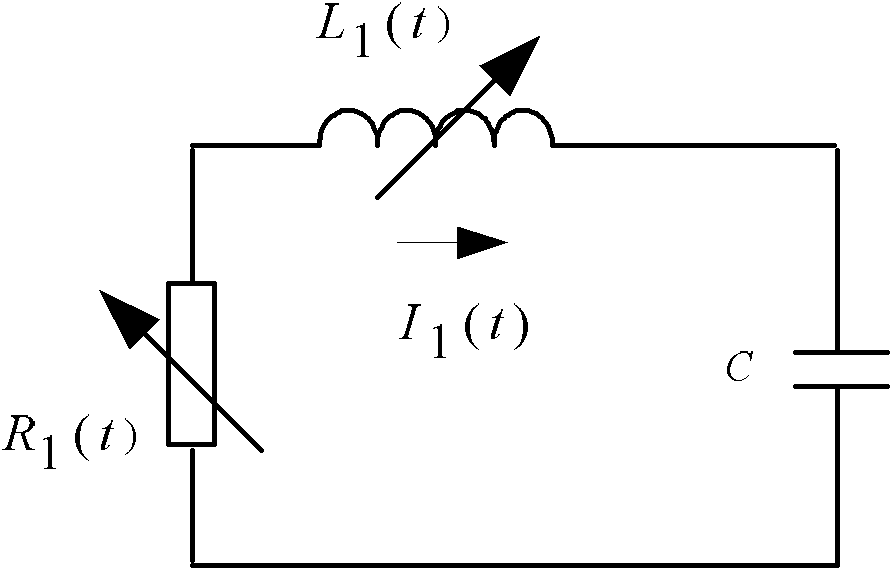

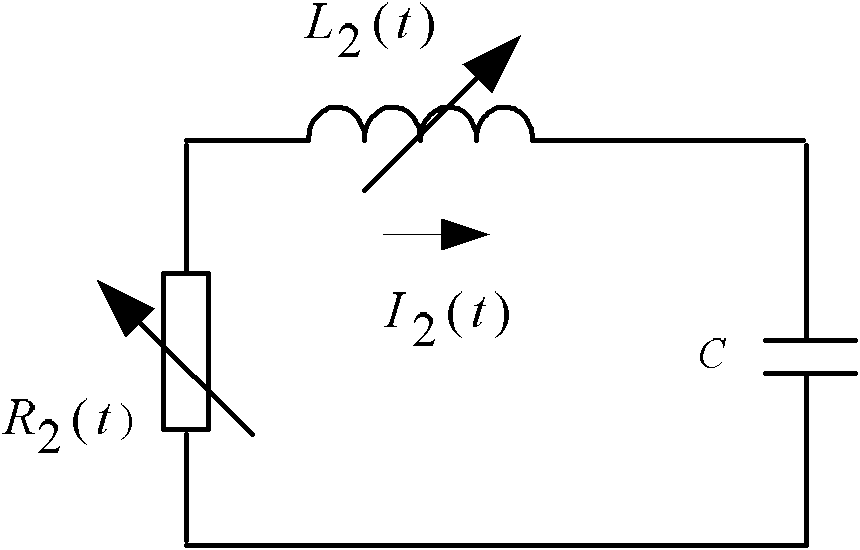

[0016] Specific implementation mode 1: the following combination Figure 1 to Figure 4 Explaining this embodiment, the capacitive load blasting magnetization compression generator with stator coil segmented operation described in this embodiment includes a stator coil 1, an armature 2 and a capacitive load 3.

[0017] The armature 2 is a cylindrical body, the stator coil 1 is divided into n-segment coils, the n-segment coils of the stator coil 1 are all spiral-shaped, and the armature 2 is arranged in the internal cavity formed by the n-segment coils, And each coil is coaxial with the armature 2. From the beginning of the armature 2, the end of each adjacent previous coil and the beginning of the subsequent coil are located on the same cross section of the armature 2, and the end of each coil Both are connected to one end of the capacitive load 3, and the end of the armature 2 is connected to the other end of the capacitive load 3.

[0018] The starting end of the armature 2 is th...

specific Embodiment approach 2

[0024] Specific implementation manner 2: the following combination figure 1 This embodiment is described. This embodiment is a further explanation of the first embodiment. Each stator coil 1 has a constant pitch, and the pitch of adjacent stator coils 1 increases geometrically from the beginning of the armature 2. Other components and connection relationships are the same as in the first embodiment.

[0025] The loss caused by the Joule heat of the resistance is very serious, especially at the end of the operation of the capacitive load blasting compression generator, because the current and current density are very large at this time. The winding method of the stator coil 1 with variable pitch can partially solve this problem. It can avoid a large number of Joules caused by unlimited increase in current density by increasing the cross-sectional area of the corresponding section of the stator coil 1 at the end of the generator to maintain the current density at a constant accep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com