Organic electroluminescent device taking metal and P-type disc-shaped compound as composite anode

An electroluminescent device and luminescence technology, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of high material cost and high energy consumption of ITO anodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

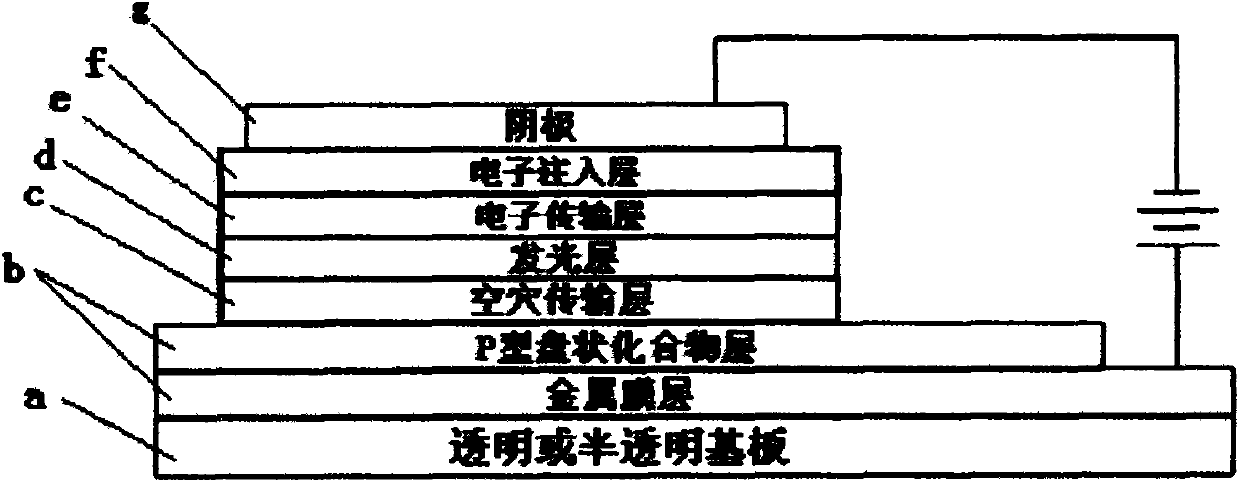

[0038] see figure 1 , an organic electroluminescence device made with the composite anode provided by the invention has a multilayer structure, and the multilayer structure can be in the following order:

[0039] a. Transparent or translucent substrate

[0040] b. Composite anode

[0041] c. Hole transport layer

[0042] d. Emissive layer

[0043] e. Electron transport layer

[0044] f. Electron injection layer

[0045] g. Cathode

[0046] The substrate a in this example is made of flat glass, the composite anode b is formed of aluminum (Al) and the P-type discotic organic compound HATCN represented by chemical formula 1a, and the hole transport layer c is made of NPD, and the chemical formula of NPD is:

[0047]

[0048] The light-emitting layer d adopts ALQ 3 ,ALQ 3 The chemical formula is:

[0049]

[0050] This light-emitting layer d also serves as the electron-transporting layer e.

[0051] The electron injection layer f is made of lithium fluoride (LiF), ...

Embodiment 2

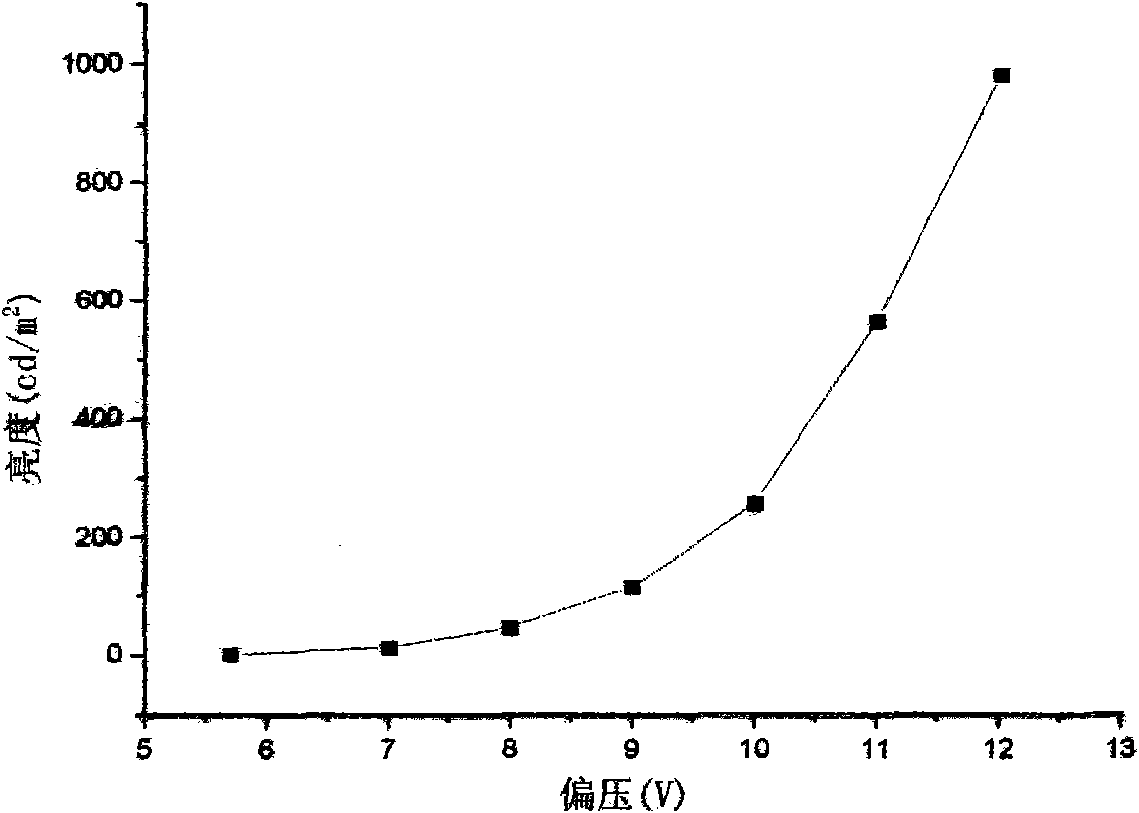

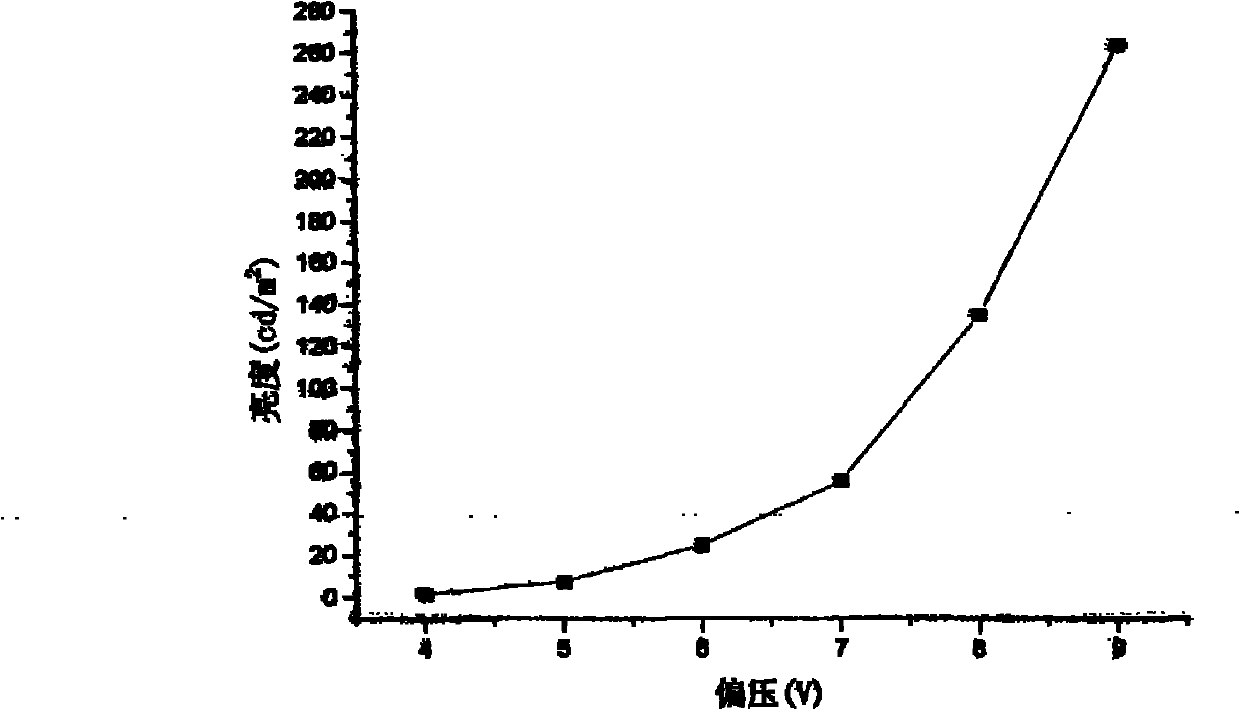

[0057] This example adopts the multilayer structure given in Example 1, the composite anode b is formed of silver (Ag) and the P-type discotic organic compound HATBM represented by chemical formula 2b, and the materials of other layers are the same as in Example 1. The deposition rate was kept at 5 Angstroms / second for silver, and its fabrication process was the same as in Example 1. The final device structure is as follows:

[0058] Glass / Ag(20nm) / HATBM(40nm) / NPD(50nm) / AlQ 3 (50nm) / LiF(0.5nm) / Al(100nm)

[0059] The voltage-brightness relationship of the light-emitting device in this example is as follows image 3 shown. It can be seen from the figure that if the metal film of the composite anode is replaced by silver, the 2 When the voltage was only 7.6 volts, this example compared the light-emitting devices made of graphene anodes provided by foreign journals ACSNANO 4(1)43-48 2010 and APPLIED PHYSICSLETTERS 96, 133301 2010, with lower voltage and higher power consumptio...

Embodiment 3

[0061] This example still adopts the multi-layer structure given in Example 1, and the substrate is made of PET (polyethylene terephthalate) plastic film, which is directly rinsed with ethanol and dried. The metal layer of the composite anode is made of aluminum and calcium mixed metal (mole percent ratio Al:Ca=90:10), and the P-type discoid organic compound layer is made of HATB and molybdenum oxide (MoO 3 ) blending (mol% ratio HATB: MoO 3 =70:30), other layer materials are the same as in Example 1. The deposition rate was kept at 3 angstroms / s for organic materials, 1 angstroms / s for LiF and molybdenum oxide, and 5 angstroms / s for aluminum, and the finally formed device structure was as follows:

[0062] PET / Al90%+Ca10%(15nm) / HATB70%+Molybdenum oxide 30%(40nm) / NPD(50nm) /

[0063] QUR 3 (50nm) / LiF(0.5nm) / Al(100nm)

[0064] The voltage-brightness relationship curve of the light-emitting device in this example is as follows Figure 4 shown.

[0065] This example compares...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com