Composite micropore filter material

A filter material and microporous technology, which is applied in the field of industrial high temperature flue gas filtration and dust removal, can solve the problems of unfavorable development and popularization, the high price of P84 fiber, and the increase of the production cost of filter material, etc., and achieves good flame retardancy and excellent high temperature resistance. The effect of improving the filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

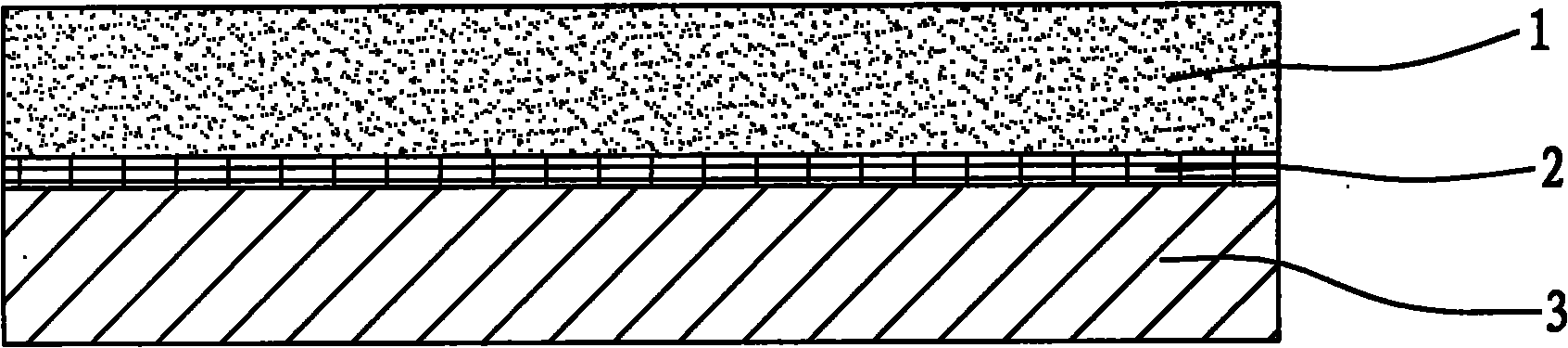

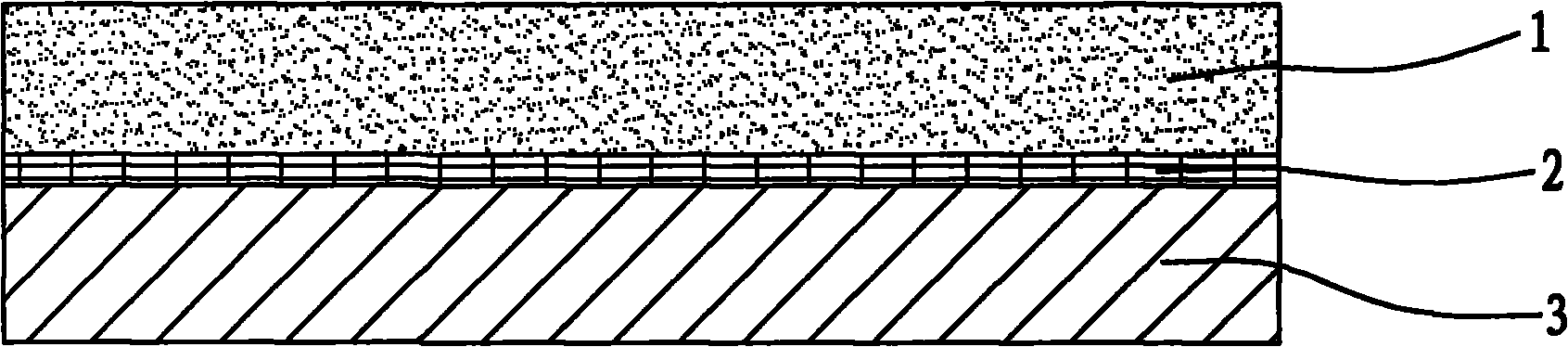

[0015] Such as figure 1 As shown, the implementation structure diagram of a composite microporous filter material provided by the present invention includes a base cloth layer 2, an upper attachment layer 1 attached to the upper side of the base cloth layer and a lower attachment layer attached to the lower side of the base cloth layer. Layer 3, the base fabric layer 2 is PTFE (polytetrafluoroethylene) filament base cloth (of course, it can also be polyimide short yarn base cloth or polysulfone fiber short yarn base cloth), and the upper adhesion layer 1 is PSA (polytetrafluoroethylene) Sulfonyl) short fiber and P84 (polyimide) short fiber blended layer, and the weight ratio of PSA short fiber and P84 fiber can be 1:1~9:1 (5:1 in this embodiment); The adhesion layer 3 adopts the PSA short fiber layer with a mass percentage of 100%, and the upper and lower adhesion layers 1 and 3 are respectively laid on the upper and lower sides of the base cloth layer 2 and then stitched toge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com