Blow/suction control method of flow separation on control surface of airplane

A control method and flow separation technology, applied in the aerospace field, can solve problems such as large gas consumption, difficult implementation, and affecting system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

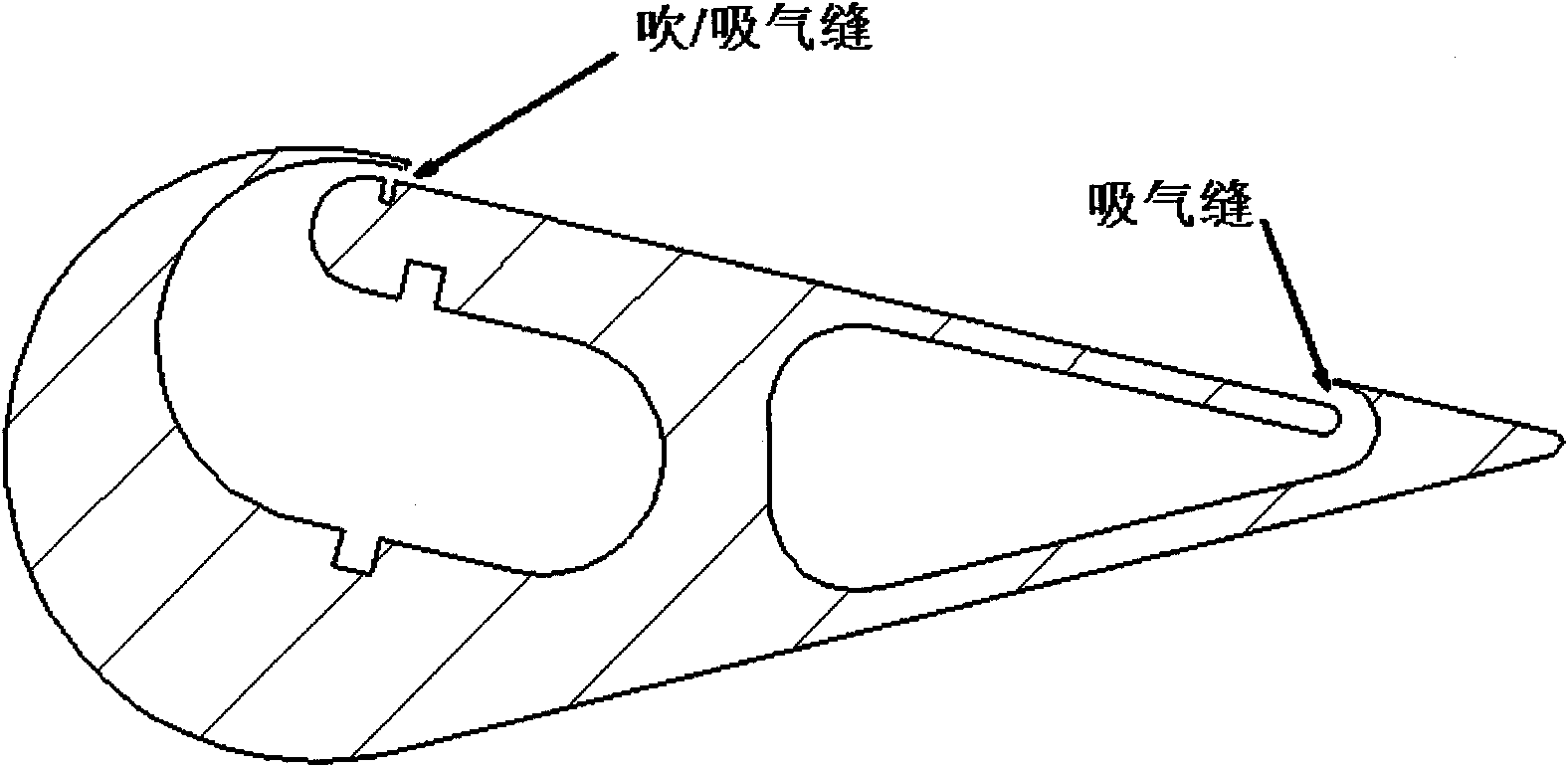

[0014] The purpose of the present invention is to provide a method for controlling the separation flow of the rudder surface by means of blowing / suction. The present invention can eliminate the flow separation on the surface of the rudder surface with a small amount of air blowing or air suction by controlling the blowing / suction on the surface of the rudder surface, thereby improving the control efficiency of the rudder surface and improving the longitudinal and lateral control of the aircraft. stable characteristics. The specific technical scheme is as follows:

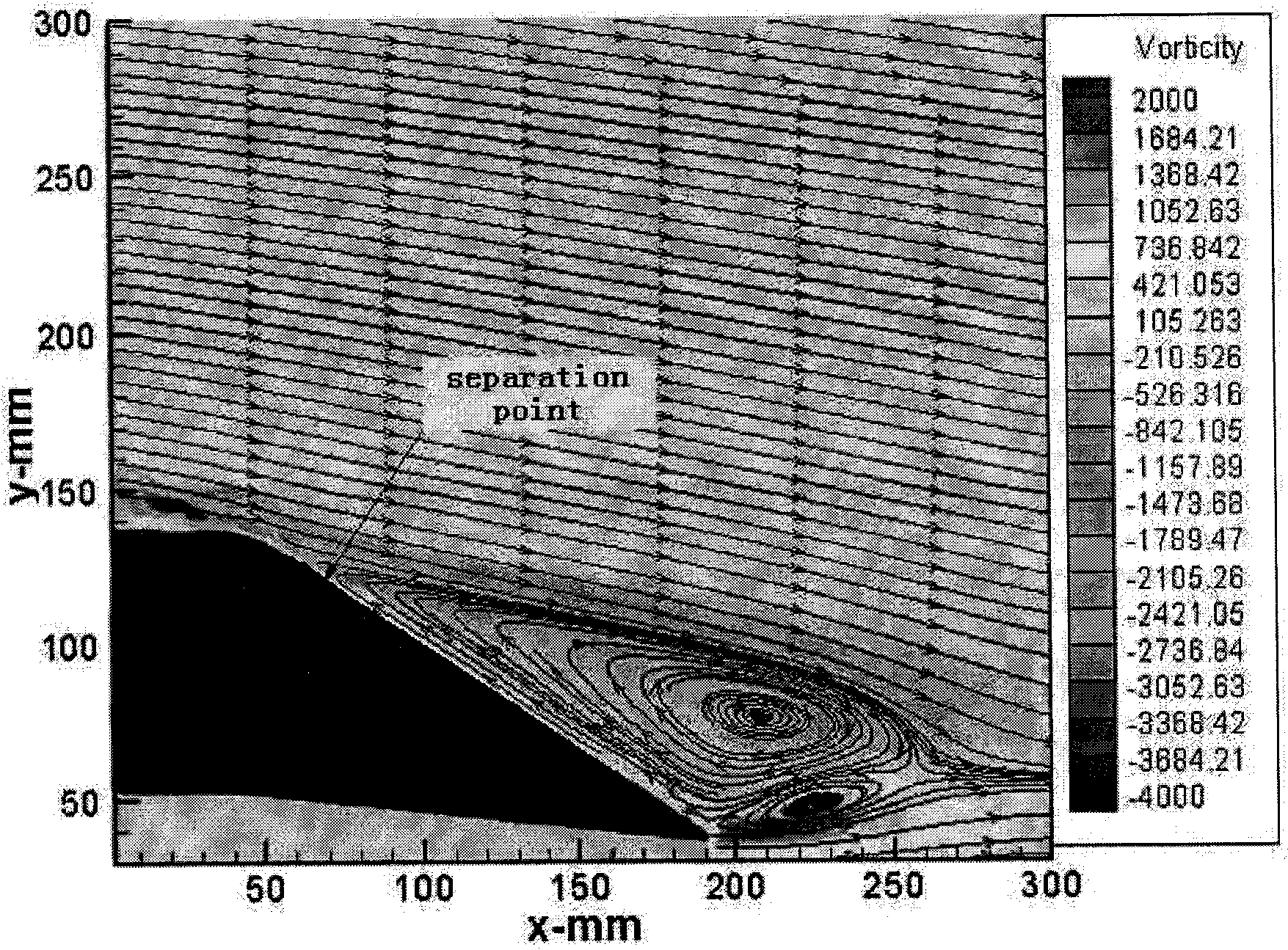

[0015] Step 1: Determine the location of the flow separation point on the rudder surface

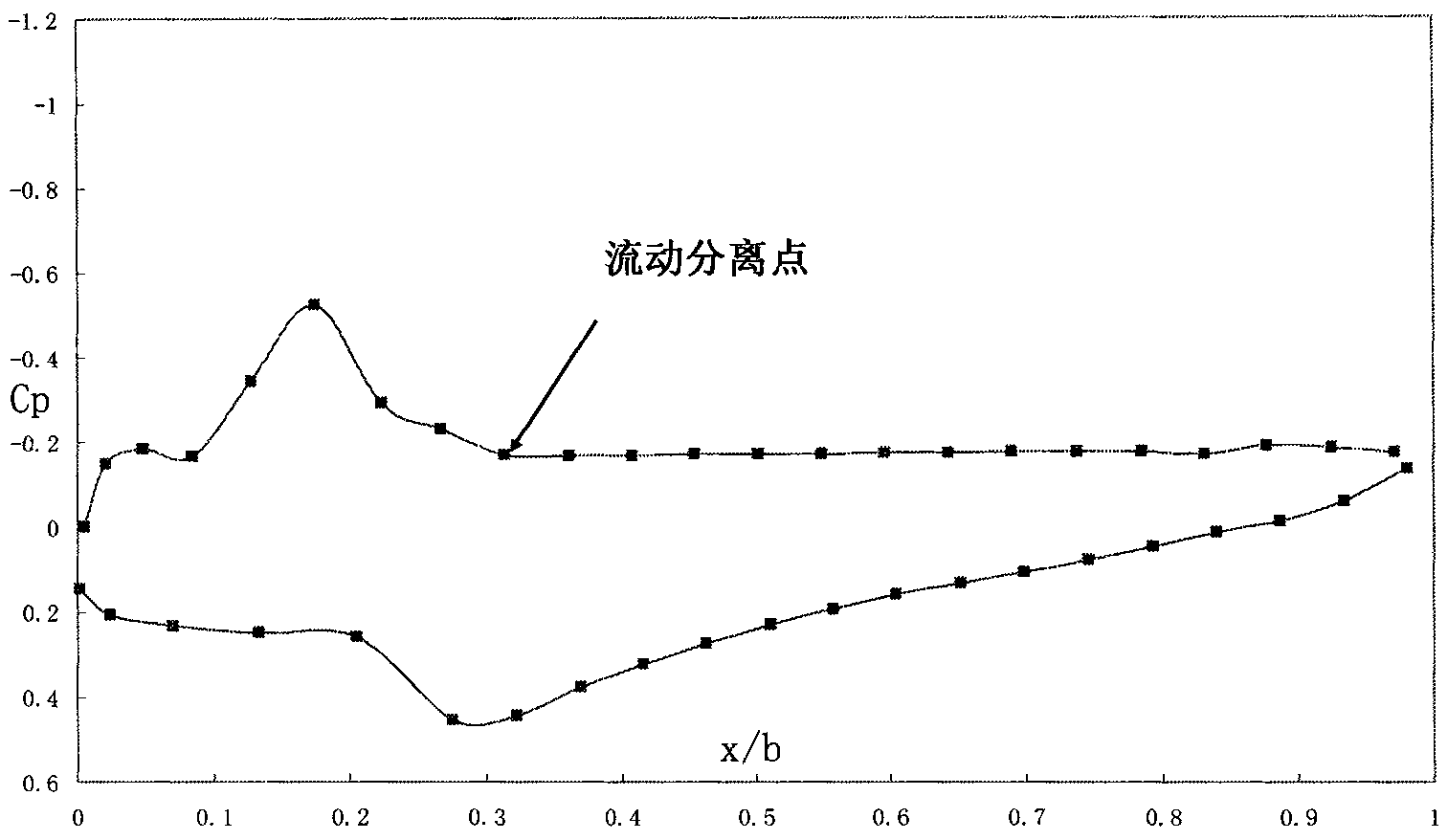

[0016] Through the pressure measurement experiment, the pressure distribution curve of the control rudder surface under the large rudder deviation can be obtained. The surface pressure distribution of the rudder surface in the separated state is a platform area. The characteristic of the platform area is that the pressure coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com