Nano titanium dioxide and preparation method thereof

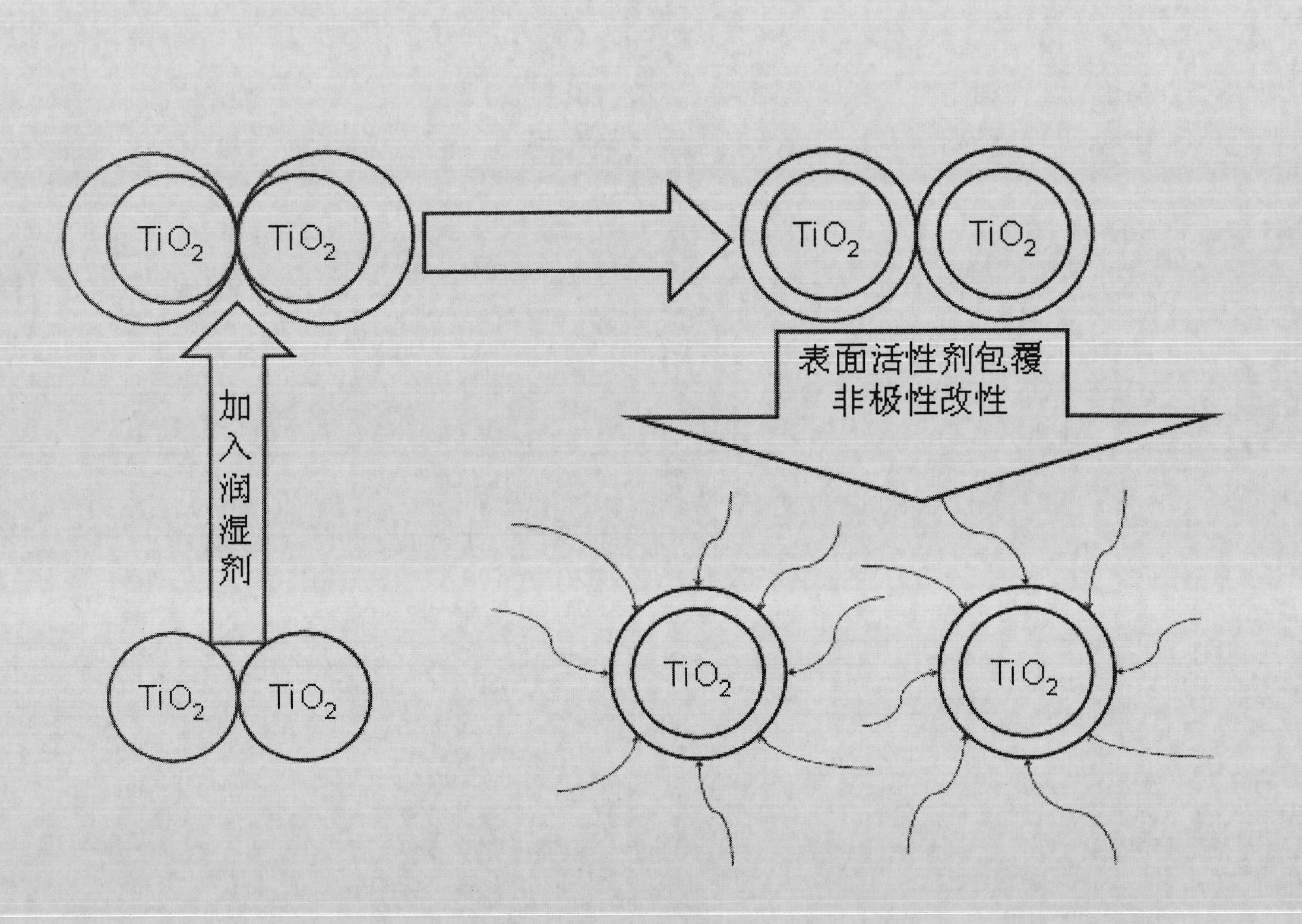

A nano-titanium dioxide and matrix technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of reducing the strength, compactness and gloss of organic polymer materials, and achieve low surface energy and difficulty in agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Add 200 grams of nano-titanium dioxide particles with a particle diameter of 18-20 nm into 1000 grams of isopropanol, and stir for 20 minutes with a stirrer. Then, add 10 grams of glyceryl monolaurate with a hydrophilic-lipophilic balance value of 5.2, and stir at a high speed for 1 hour, so that glyceryl monolaurate is dissolved in isopropanol and evenly coated on the surface of the nano-titanium dioxide particles. Then, dry under reduced pressure at a temperature of 60° C. for 24 hours to obtain nano-titanium dioxide surface-modified with glyceryl monolaurate.

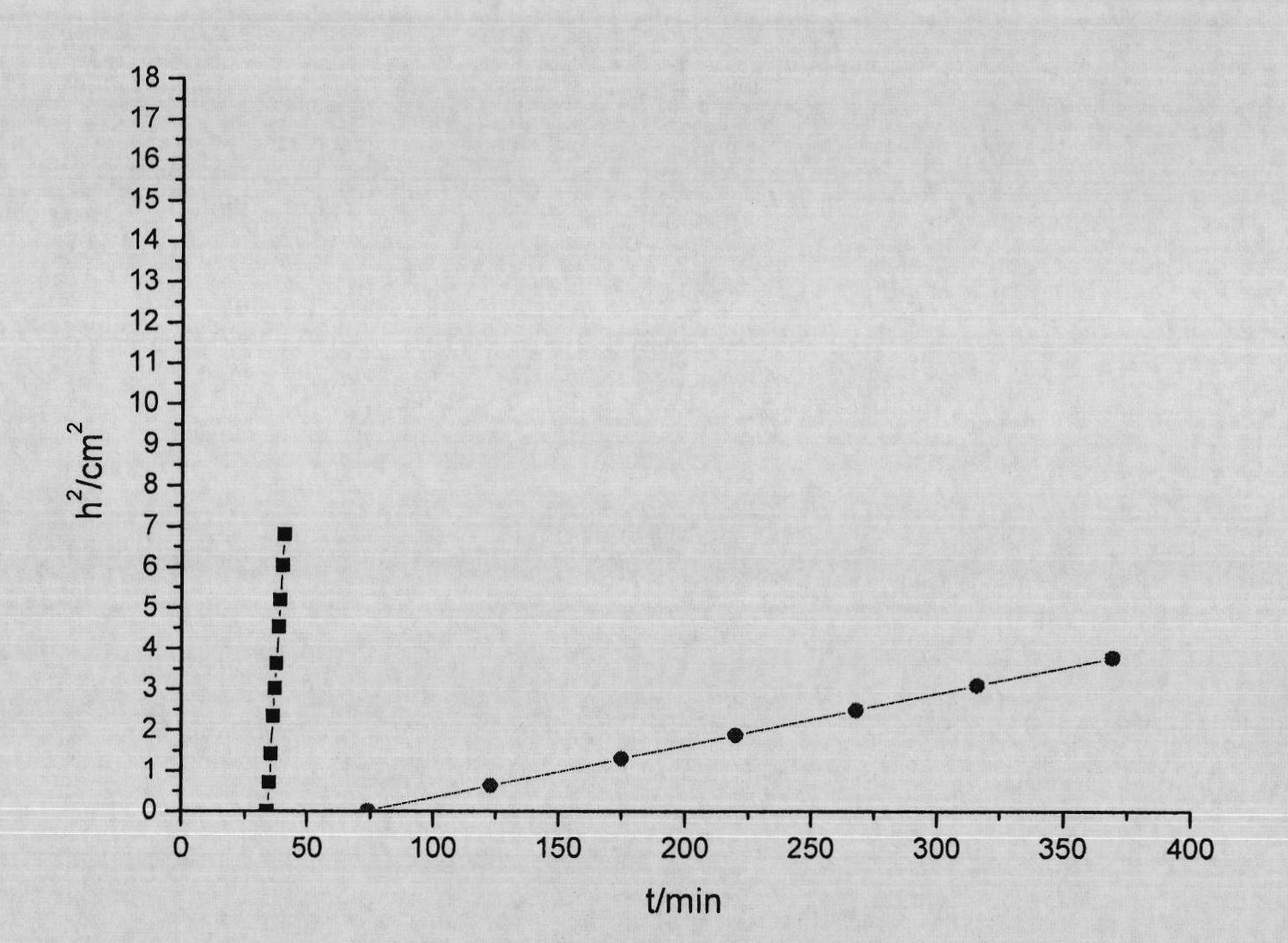

[0055] Wetting height and time (h 2 ~t) the relationship is as image 3 shown. Before modification, wetting height and time (h 2 ~t) The slope k of the relationship line is relatively large, k=0.2437, at this time, the hydrophilicity is strong, and the contact angle between nano-titanium dioxide and water can be set to 5°. After modification with glyceryl monolaurate, the wet height and time (h 2 ~t) The ...

Embodiment 2

[0058] Add 500 grams of nano-titanium dioxide particles with a particle diameter of 50-60 nm into 1000 grams of ethanol, and stir for 30 minutes with a stirrer. Then, add 20 grams of sorbitan tristearate Span 65 with a hydrophilic-lipophilic balance value of 2.1, and stir at high speed for 1.5 hours, so that Span 65 is completely dissolved in ethanol and evenly coated on the surface of nano-titanium dioxide particles superior. Then, dry under reduced pressure at a temperature of 60° C. for 24 hours to obtain Span 65 surface-modified nano-titanium dioxide.

[0059] Wetting height and time (h 2 ~t) the relationship is as Figure 5 shown. Before modification, the slope k=0.342, the nano-titanium dioxide exhibits strong hydrophilicity, and the contact angle between the nano-titanium dioxide and water can be set to 5°. After modified by Span 65, h 2 The slope k of the ~t relationship line becomes very small, k=0.000599, and the contact angle θ increases obviously. Calculated ...

Embodiment 3

[0062] 300 grams of particle diameters are 10-15nm nano-titanium dioxide particles and 18 grams of propylene glycol monostearate with a hydrophilic-lipophilic balance value of 3.4 are added in 1000 grams of methanol, stirred at a high speed for 1.5 hours, so that the monostearic acid The propylene glycol ester is completely dissolved in methanol and uniformly coated on the surface of nano titanium dioxide particles. Then, dry under reduced pressure at a temperature of 60° C. for 24 hours to obtain propylene glycol monostearate surface-modified nano-titanium dioxide.

[0063] The wetting height and time (h 2 ~t) the relationship is as Figure 7 shown. Before modification, h 2 The slope k of the relationship line between ~t is relatively large, and k=0.3089. At this time, the hydrophilicity is strong, and the contact angle between nano-titanium dioxide and water can be set to 5°. After modification with propylene glycol monostearate, h 2 The slope k of the ~t relationship l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com