Method for preparing D-phenylalanine through dynamic kinetic resolution

A dynamic kinetics, phenylalanine technology, applied in chemical instruments and methods, preparation of cyanide reactions, preparation of organic compounds, etc., can solve the problems of long separation time, mild conditions, and large production-to-dissolve ratio. , to achieve the effect of improving the split yield, stable product quality and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

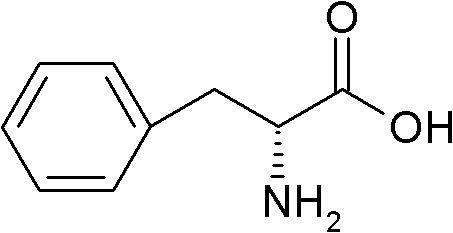

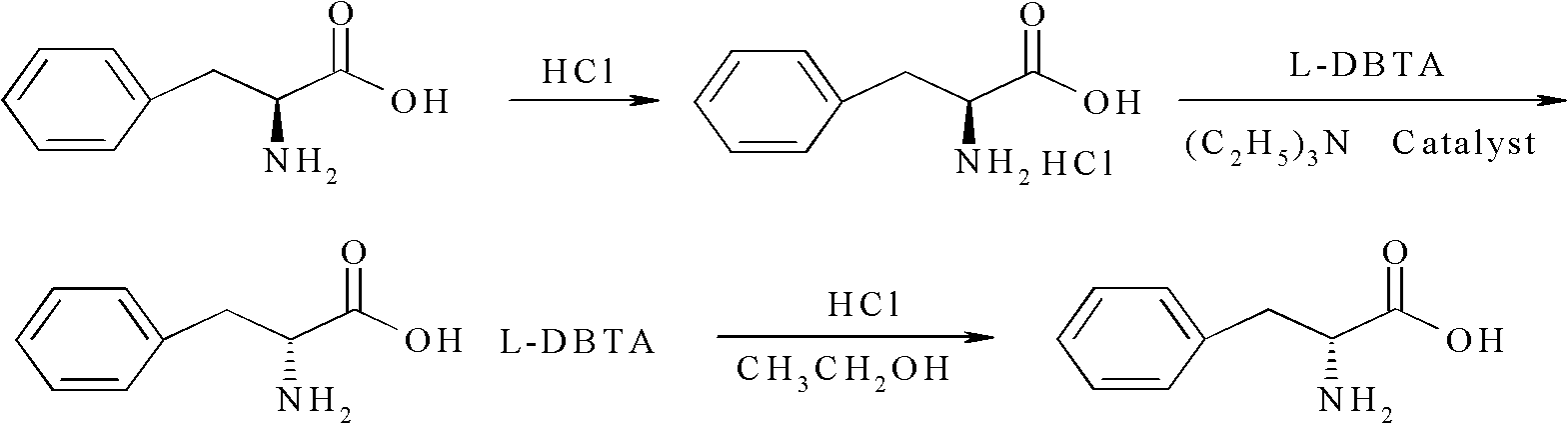

[0029] (1) Preparation of L-phenylalanine hydrochloride:

[0030] Add 99.1g (0.60mol) of L-phenylalanine and 241g of 10% (0.66mol) hydrochloric acid to a stirred reactor, stir at room temperature until the solids are completely dissolved, then evaporate the reaction solution to dryness to obtain phenylalanine salt Salt 121g.

[0031] (2) Preparation of D-phenylalanine L-DBTA di-salt:

[0032] In a reactor with stirring, heating and thermometer, 40.3g (0.20mol) of L-phenylalanine hydrochloride obtained in step (1) was dissolved in 82ml of methanol, and 2.5g (0.01mol) of 2- Aldehydpyridine, stirred and heated to 65°C. Begin to add dropwise the mixed solution that is made up of 35.8g (0.10mol) L-DBTA, 20.2g (0.2mol) triethylamine, 72ml methanol, along with the adding of mixed solution, D-phenylalanine·L-DBTA disalt It also crystallized gradually, and the mixed solution was added after 1.5 hours; reacted for another 30 minutes, and the system was cooled to room temperature, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com