Technology for producing low-caffeine catechin through non-solvent method

A low-caffeine, non-solvent technology, applied in organic chemistry and other directions, can solve the problems of complicated operation, great influence on product yield, toxic chloride, etc., and achieve the effects of simple and convenient operation, green and safe products, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

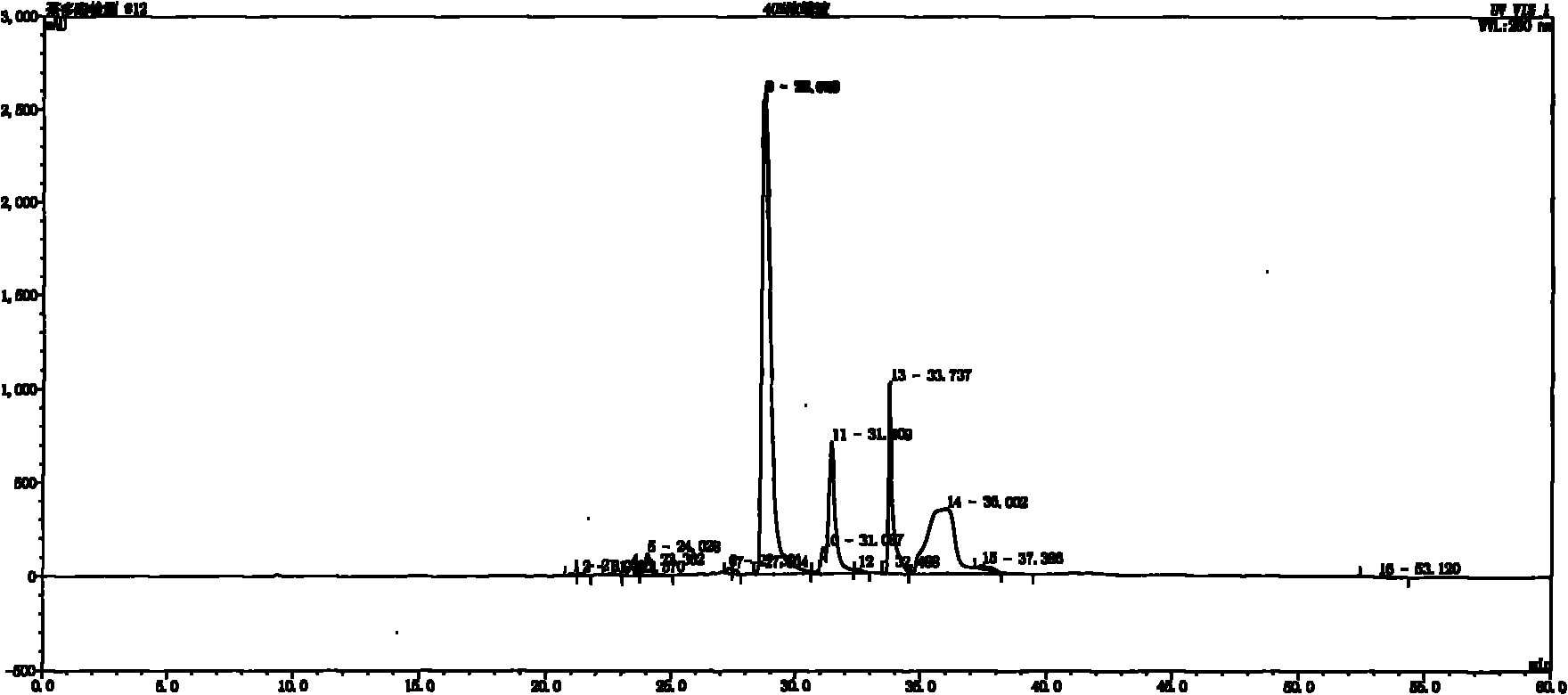

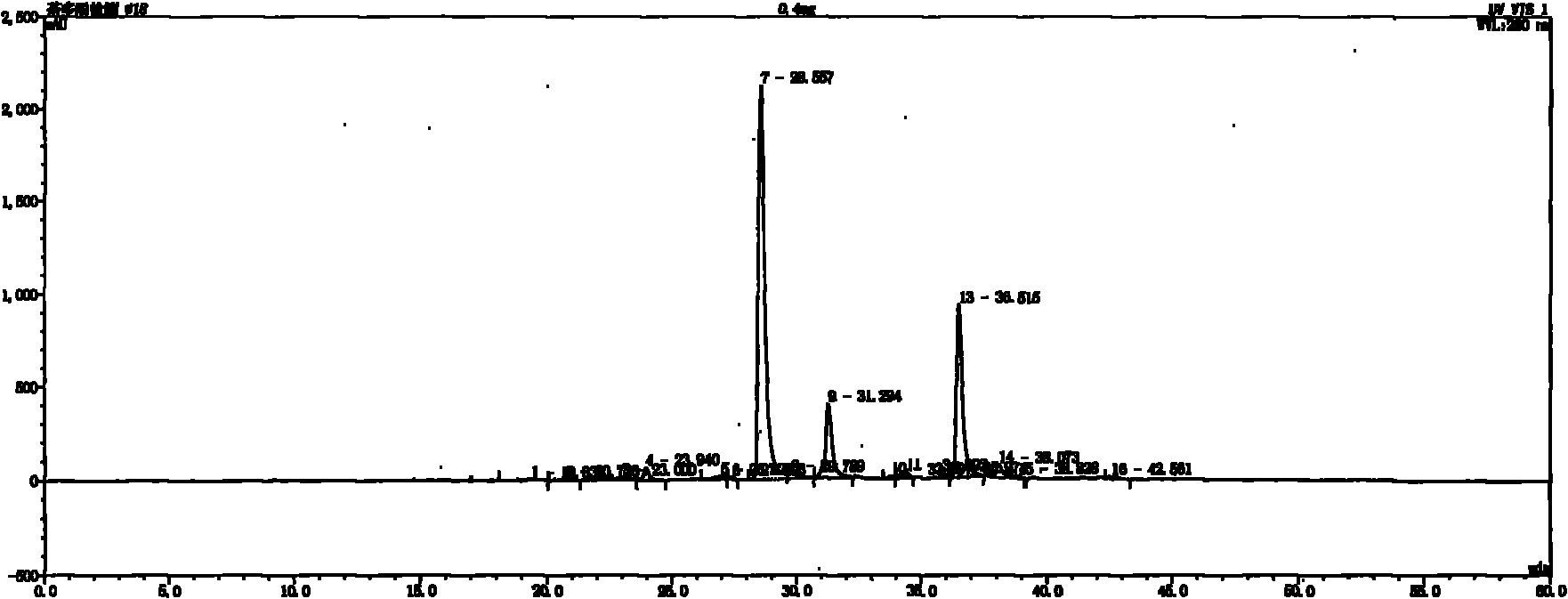

Image

Examples

example 1

[0025] 1) Weigh 1000.0g green tea, add 12L of deionized water at a solid-liquid ratio of 1:12, 45°C, ultrasonic frequency 28KHz, ultrasonic extraction for 30min, stop for 2min every 15min, filter the extract, repeat the extraction once, combine the two Filtrate, to obtain extract 17L;

[0026] 2) The filtrate was allowed to stand at 4°C for stratification, and the clarified liquid was separated with a ceramic membrane with a pore size of 100nm, the separation pressure was 0.1MPa, and the flow rate was 20ml / min, and the permeate was collected; the permeate was concentrated with a nanofiltration membrane (200dal) to 1 / 2 of the original volume;

[0027] 3) Load the concentrated solution onto a well-balanced lignocellulose resin chromatography column (the column specification is 20cm×1500mm), let it stand for 30min, and elute the four bed layers sequentially with 5% ethanol with a pH value of 5 (flow rate 1.9L / min), 35% ethanol with a pH value of 5 elutes 3 bed layers (flow rate ...

example 2

[0031] 1) Weigh 500.0g of green tea, add 7.5L of deionized water at a solid-to-liquid ratio of 1:15, 50°C, ultrasonic frequency 40KHz, ultrasonic extraction for 30min, stop for 2min every 15min, filter the extract, repeat the extraction once, combine Secondary filtrate to obtain 11L of extract;

[0032] 2) The filtrate was allowed to stand at 5°C for stratification, and the clarified liquid was separated with a ceramic membrane with a pore size of 200nm at a separation pressure of 0.1MPa and a flow rate of 20ml / min to collect the permeate; the permeate was concentrated with a nanofiltration membrane (400dal) to 1 / 2 of the original volume;

[0033] 3) Load the concentrated solution onto a well-balanced lignocellulose resin chromatographic column (the column specification is 20cm×1500mm), let it stand for 30min, and elute the four bed layers sequentially with 15% ethanol with a pH value of 3.5 (flow rate 2.0L / min), 45% ethanol with a pH value of 3.5 eluted 3 bed layers (flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com