Method for removing iron through external circulation standing and cooling during continuous hot-dipping of zinc and aluminum

A technology of hot-dip galvanizing and extracorporeal circulation, which is used in hot-dip galvanizing process, coating, metal material coating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Introduce this embodiment in detail below in conjunction with the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementation example.

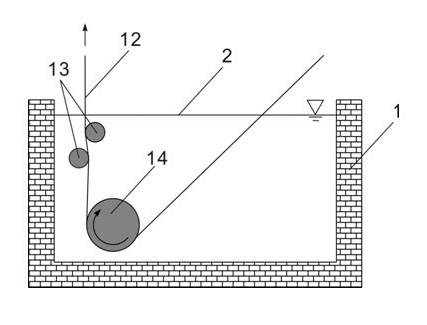

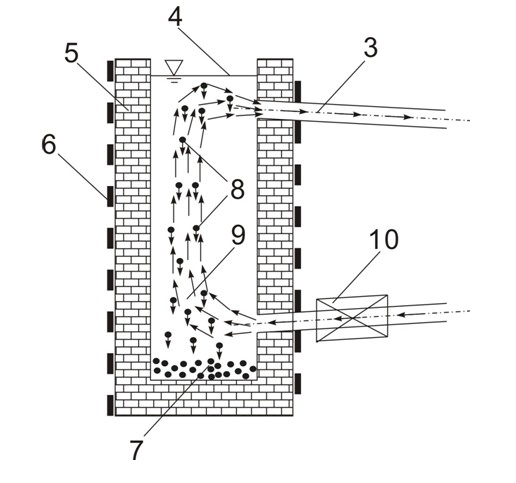

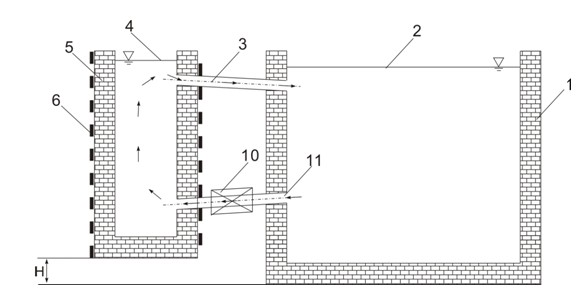

[0031] combine figure 1 , figure 2 and image 3 As shown, the method for continuous hot-dip galvanized aluminum medium and extracorporeal circulation of the present invention for static cooling and iron removal includes a galvanized zinc pot 1 and a low-temperature static zinc pot 5 . The position of the low-temperature static zinc pot 5 is H higher than the galvanized zinc pot 1, and the height difference is 30-50 cm. The hot-dip galvanizing process of the steel plate is completed in the galvanized zinc pot, and the low-temperature static zinc pot is used to cool down and remove iron. The galvanized zinc pot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com