Dual-phase steel color metallographic coloring agent and color display method thereof

A color metallography and dye technology, applied in metal material coating process, preparation of test samples, instruments, etc., can solve the problems of indistinguishability, affect product organization judgment, affect scientific research and product development, etc., and achieve stable performance. , Significant economic and social benefits, and novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

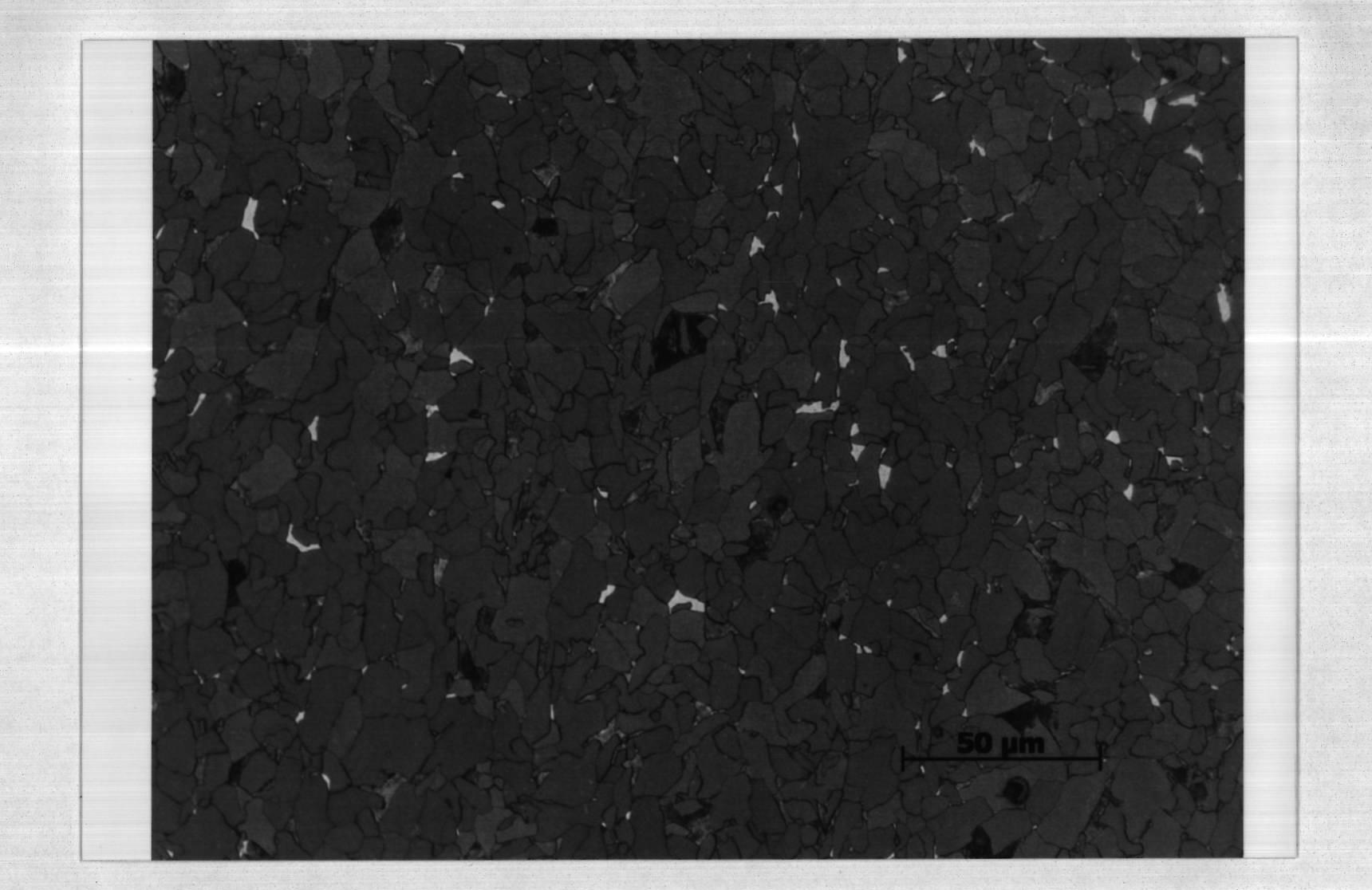

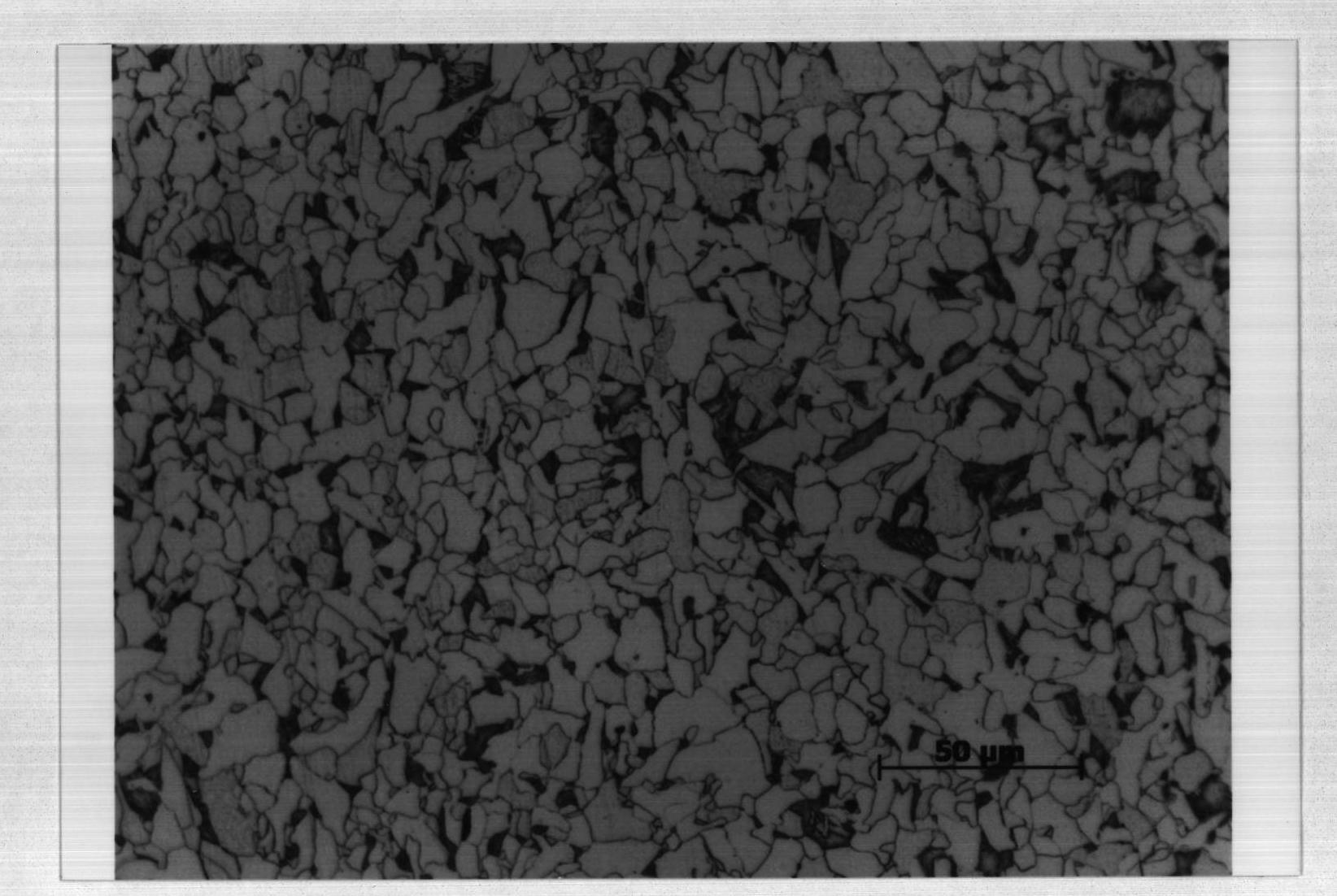

Image

Examples

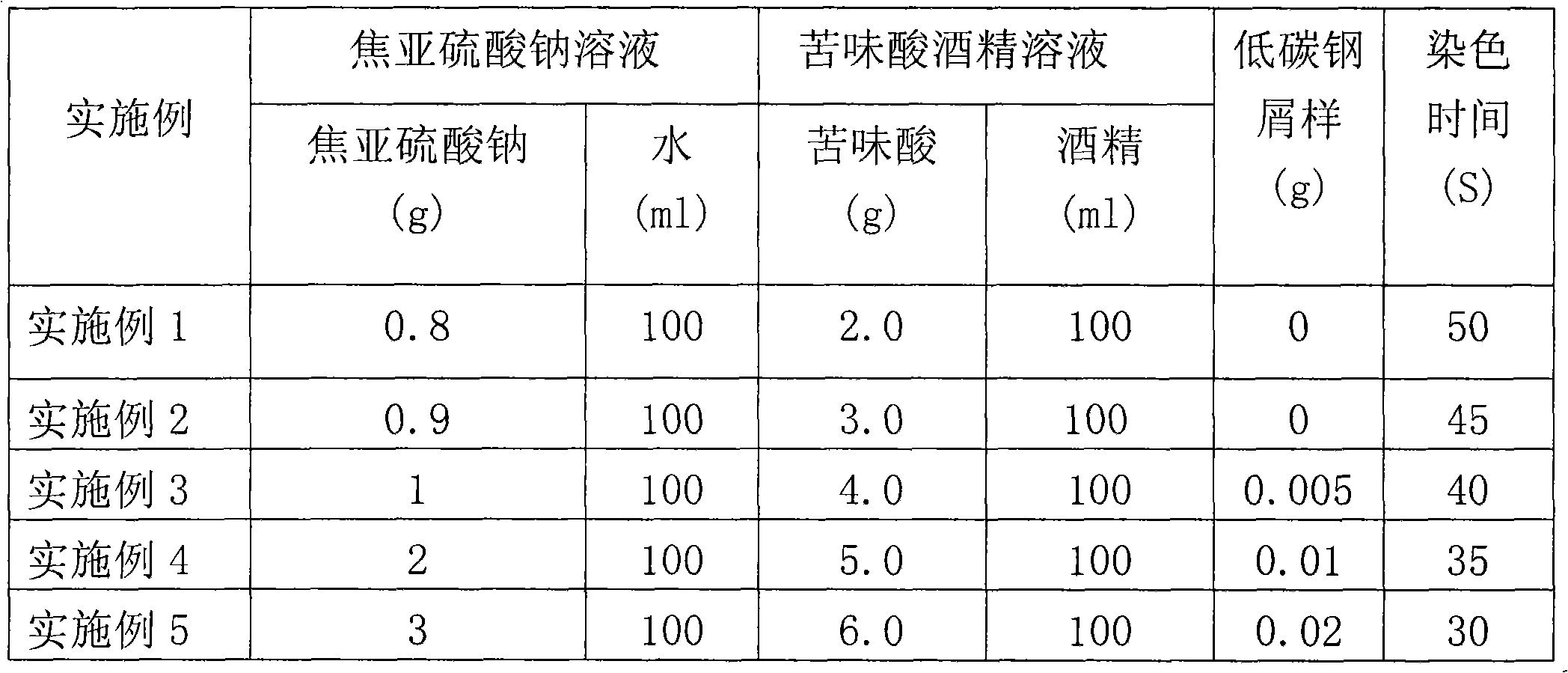

Embodiment 1

[0033] At a constant temperature of 30°C, first dissolve sodium metabisulfite in water to make a 0.8% sodium metabisulfite solution, then add 2% picric acid alcohol according to the specified volume ratio, and mix it into a dye solution. The specimen is then immersed in the stain solution. Its content of sodium metabisulfite solution, picric acid alcohol concentration, film-forming time are listed in Table 1.

Embodiment 2

[0035] With embodiment 1 method. Its sodium metabisulfite and picric acid alcohol solution volume, film-forming time are listed in Table 1.

Embodiment 3

[0037] With embodiment 1 method. Its sodium metabisulfite and picric acid alcohol solution volume, film-forming time are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com