Nanometer garnet woven fabric

A technology of garnet textile cloth and textile cloth, which is applied in the direction of textiles, papermaking, and fiber treatment, and can solve the problems of low mineral powder content, reduced fabric efficacy, and low efficiency of nano-ore particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

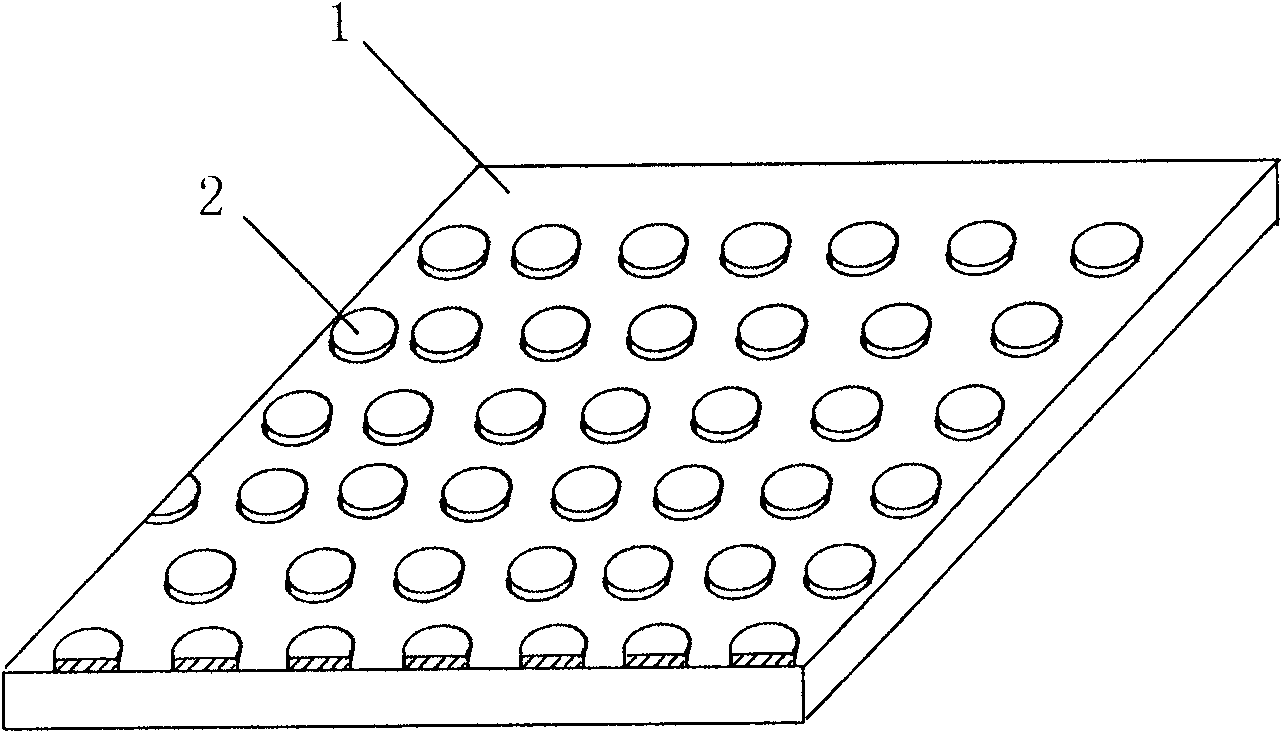

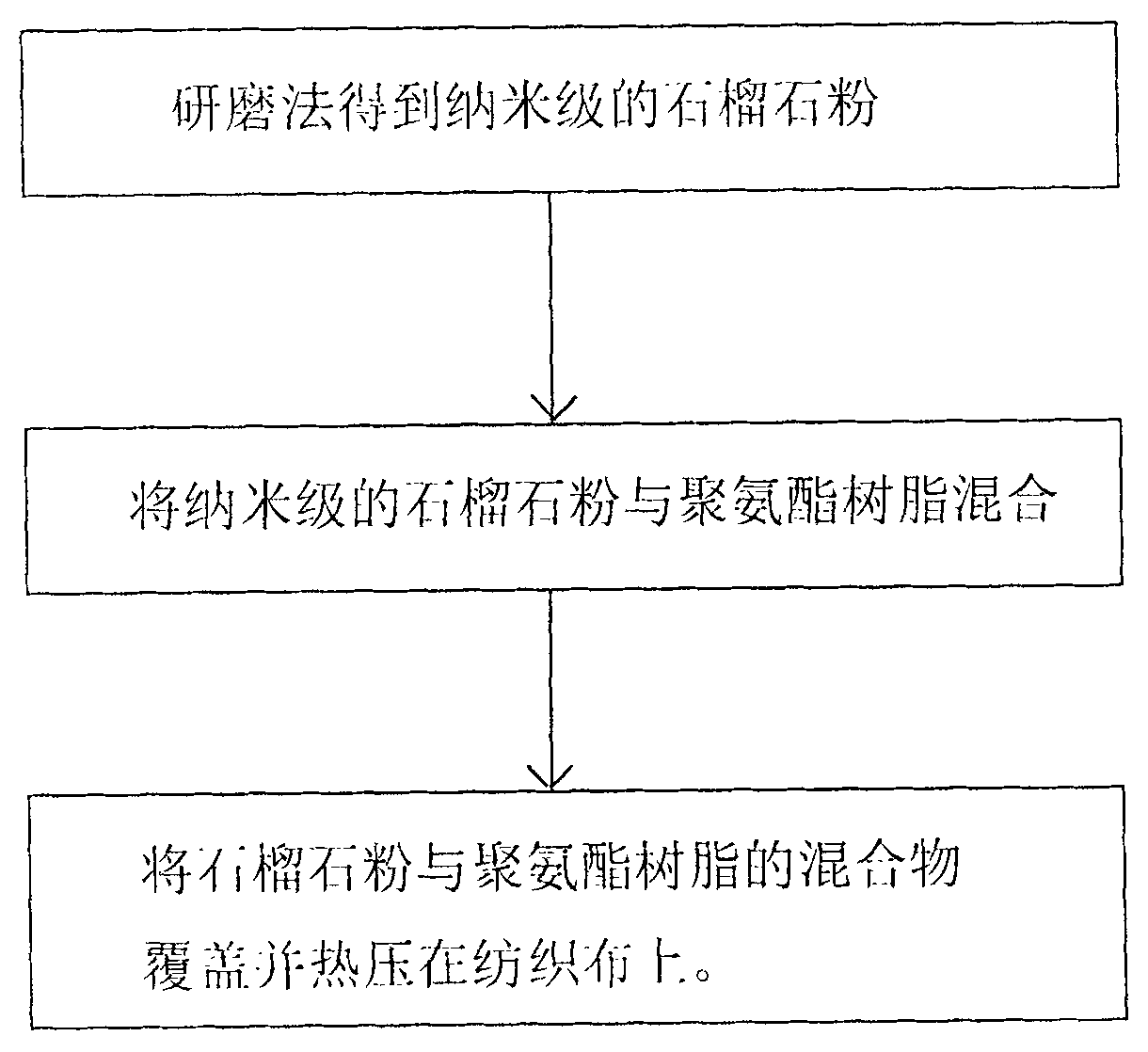

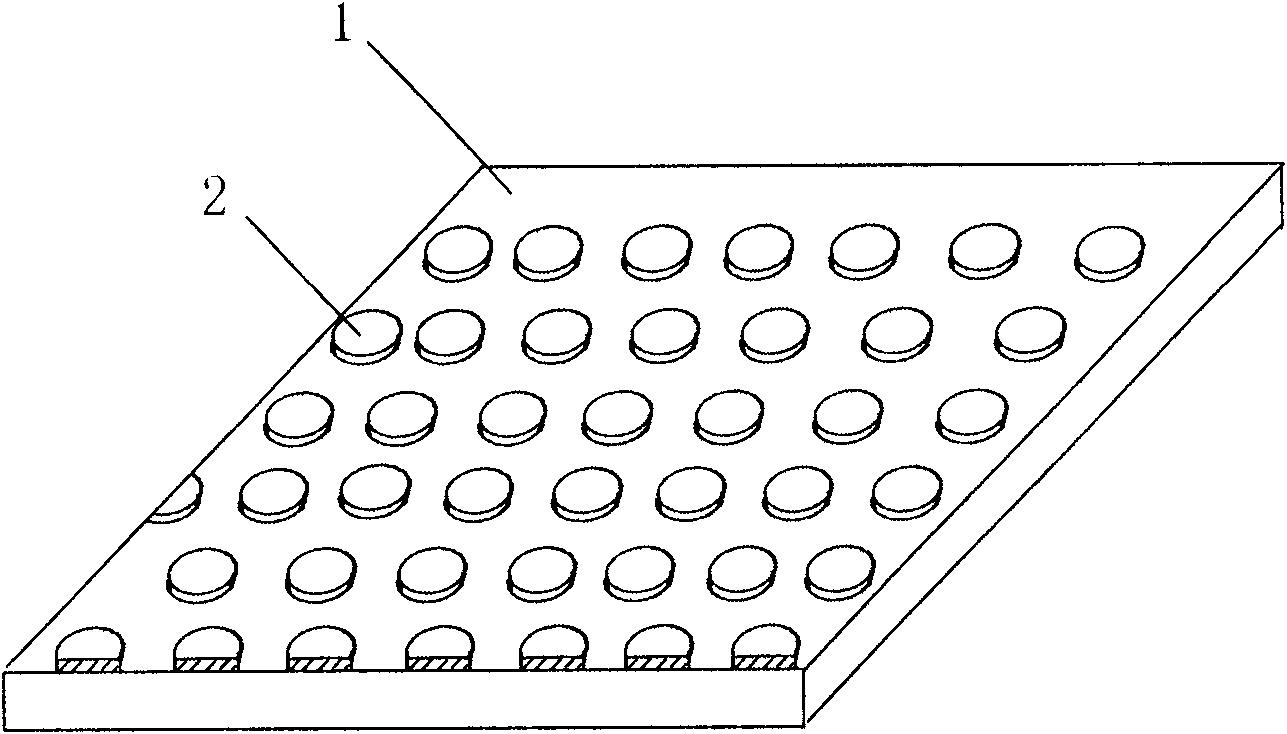

[0024] like Figure 1 to Figure 2 Shown, a kind of manufacture method of nanometer garnet woven cloth is characterized in that described method comprises the following steps:

[0025] 1) Obtain nano-scale garnet powder by mechanical grinding;

[0026] 2) sintering at high temperature after mixing the garnet powder obtained in the previous step with silica powder;

[0027] 3) the sintered product obtained in the previous step is mixed with the polyurethane resin particles in a screw mixer;

[0028] 4) The mixture containing polyurethane resin particles obtained in the previous step is covered and heat-pressed on the woven cloth.

[0029] The manufacture method of described nano garnet woven cloth is characterized in that

[0030] 1) the described step of obtaining garnet powder by mechanical grinding method is:

[0031] dry-grinding the garnet to a particle size of less than 50 microns, and then jet-grinding to obtain garnet powder with a particle size of less than 500 nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com