Material for lithium-sulfur battery current collector and preparation method thereof

A technology for lithium-sulfur batteries and current collectors is applied in the field of materials and preparations of current collectors for lithium-sulfur batteries, which can solve the problems that restrict the high-rate discharge performance and cycle performance of lithium-sulfur batteries, and improve the high-rate discharge performance and cycle performance. , Good mechanical strength, high capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

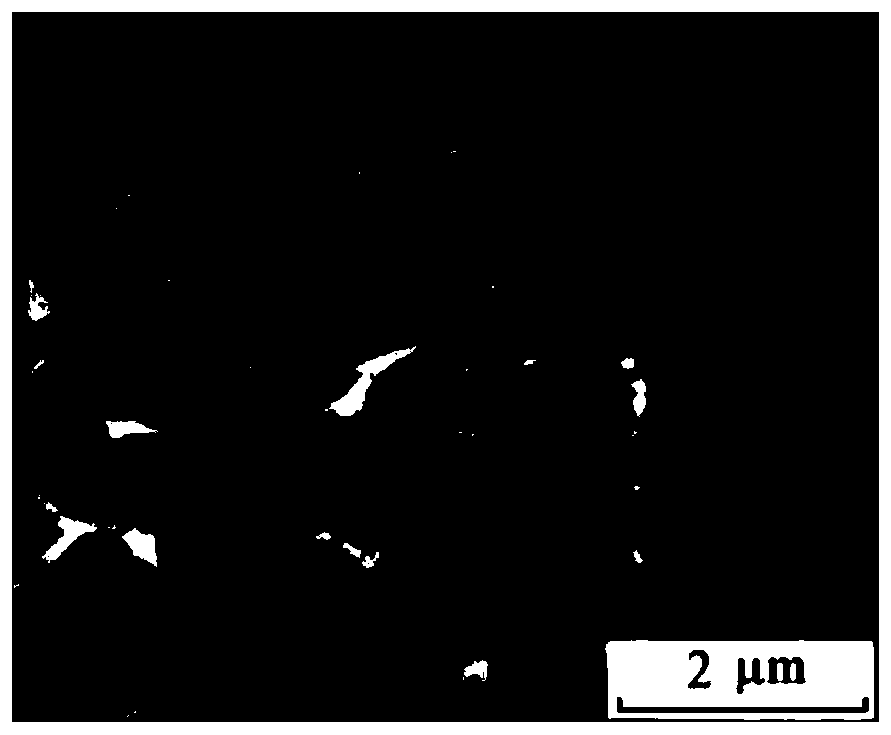

[0025] The material used for the lithium-sulfur battery current collector is Ni with a one-dimensional nano-array structure 0.25 co 0.75 (OH) 2 nanoscale materials.

[0026] The preparation method of the current collector material for lithium-sulfur batteries comprises the following steps:

[0027] (1) Preparation of basic cobalt-nickel carbonate nanowire array: first cut the foam into a block with a size of 3 × 2cm, place it in 40ml of concentrated hydrochloric acid with a mass fraction of 37%, and ultrasonically wash it for 10 minutes, and wash the NiO layer; Then use deionized water to rinse the surface acid, place it in deionized water and clean it for 10 minutes, and finally use ethanol solution ultrasonic cleaning for 10 minutes to remove the surface organic matter, and obtain the finished foamed nickel block; 2mmol mass fraction of 10% Co ( NO) 3 6H 2 O, 8mmol mass fraction of 20% NH 4 F and 10mmol mass fraction are 70% CO(NH 2 ) 2 Dissolve in 36mL deionized wat...

Embodiment 2

[0031] The material used for the lithium-sulfur battery current collector is Ni with a one-dimensional nano-array structure 0.25 co 0.75 (OH) 2 nanoscale materials.

[0032] The preparation method of the current collector material for lithium-sulfur batteries comprises the following steps:

[0033] (1) Preparation of basic cobalt-nickel carbonate nanowire array: first, the foam is cut into a block with a size of 3 × 3 cm, placed in 50 ml of concentrated hydrochloric acid with a mass fraction of 37%, and ultrasonically washed for 15 minutes, and the NiO layer is washed clean; Then use deionized water to rinse the surface acid, place it in deionized water and clean it for 15 minutes, and finally use ethanol solution ultrasonic cleaning for 15 minutes to remove surface organic matter, and obtain the foamed nickel block that has been processed; 2mmol mass fraction is 5% Co ( NO) 3 6H 2 O, 8mmol mass fraction of 15% NH 4 F and 10mmol mass fraction are 60% CO(NH 2 ) 2 Dissol...

Embodiment 3

[0037] The material used for the lithium-sulfur battery current collector is Ni with a one-dimensional nano-array structure 0.25 co 0.75 (OH) 2 nanoscale materials.

[0038] The preparation method of the current collector material for lithium-sulfur batteries comprises the following steps:

[0039] (1) Preparation of basic cobalt-nickel carbonate nanowire array: first cut the foam into a block with a size of 3 × 2cm, place it in 40ml of concentrated hydrochloric acid with a mass fraction of 37%, and ultrasonically wash it for 20 minutes, and wash the NiO layer; Then use deionized water to clean the surface acid, place it in deionized water and clean it for 20 minutes, and finally use ethanol solution ultrasonic cleaning for 20 minutes to remove surface organic matter, and obtain the finished nickel foam block; 2mmol mass fraction of 15% Co ( NO) 3 6H 2 O, 8mmol mass fraction of 25% NH 4 F and 10mmol mass fraction are 80% CO(NH 2 ) 2 Dissolve in 36mL deionized water to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com