Range hood and cooker integrated machine

The technology of a range hood and an all-in-one machine is applied in the direction of removing oil fume, household stoves, household appliances, etc. It can solve the problems of inability to remove oil fume, indoor environmental pollution, and oil fume diffusion, and prolong the cleaning cycle and the service life of the whole machine. The effect of high fume absorption rate and uniform negative pressure area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

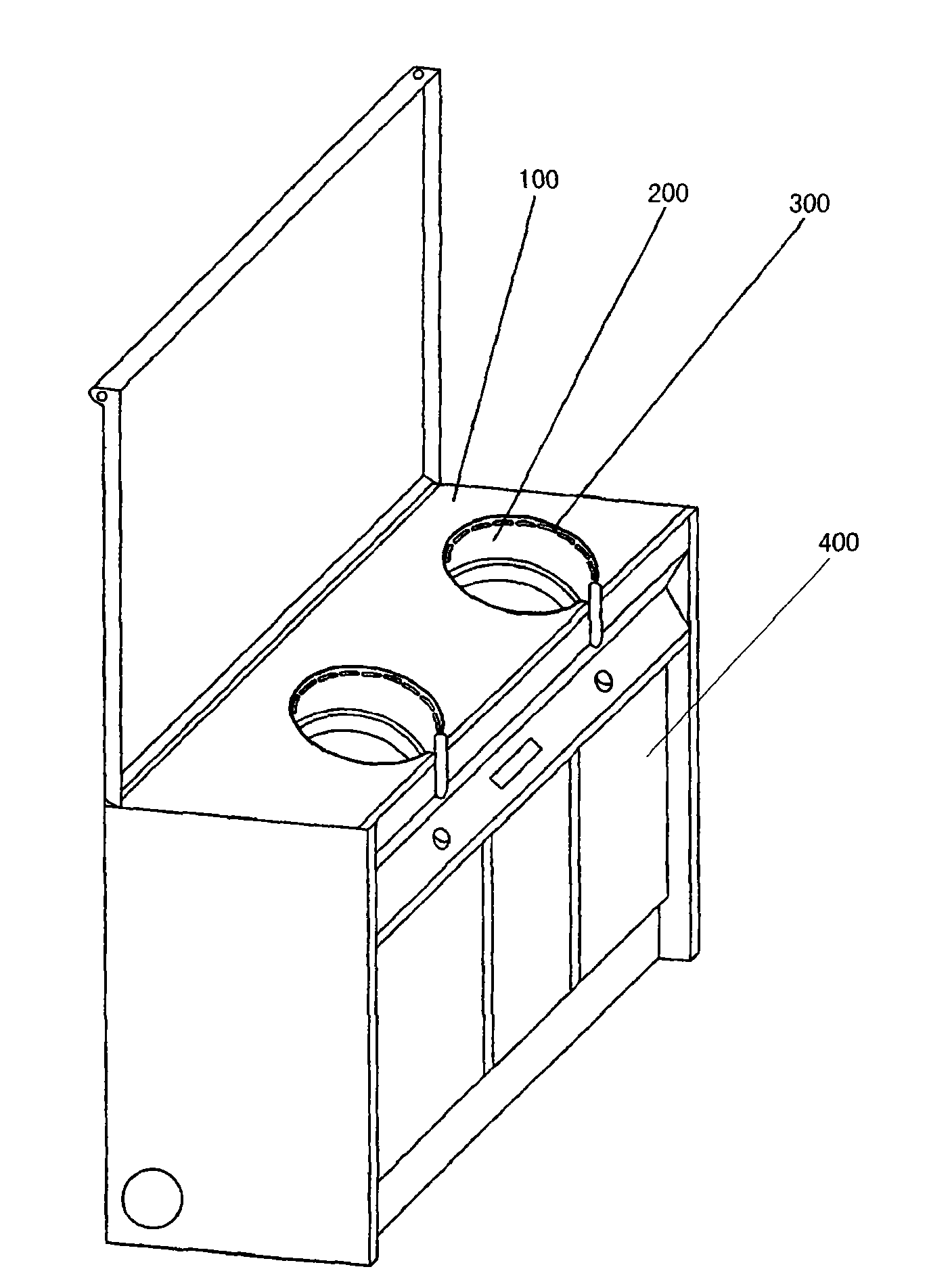

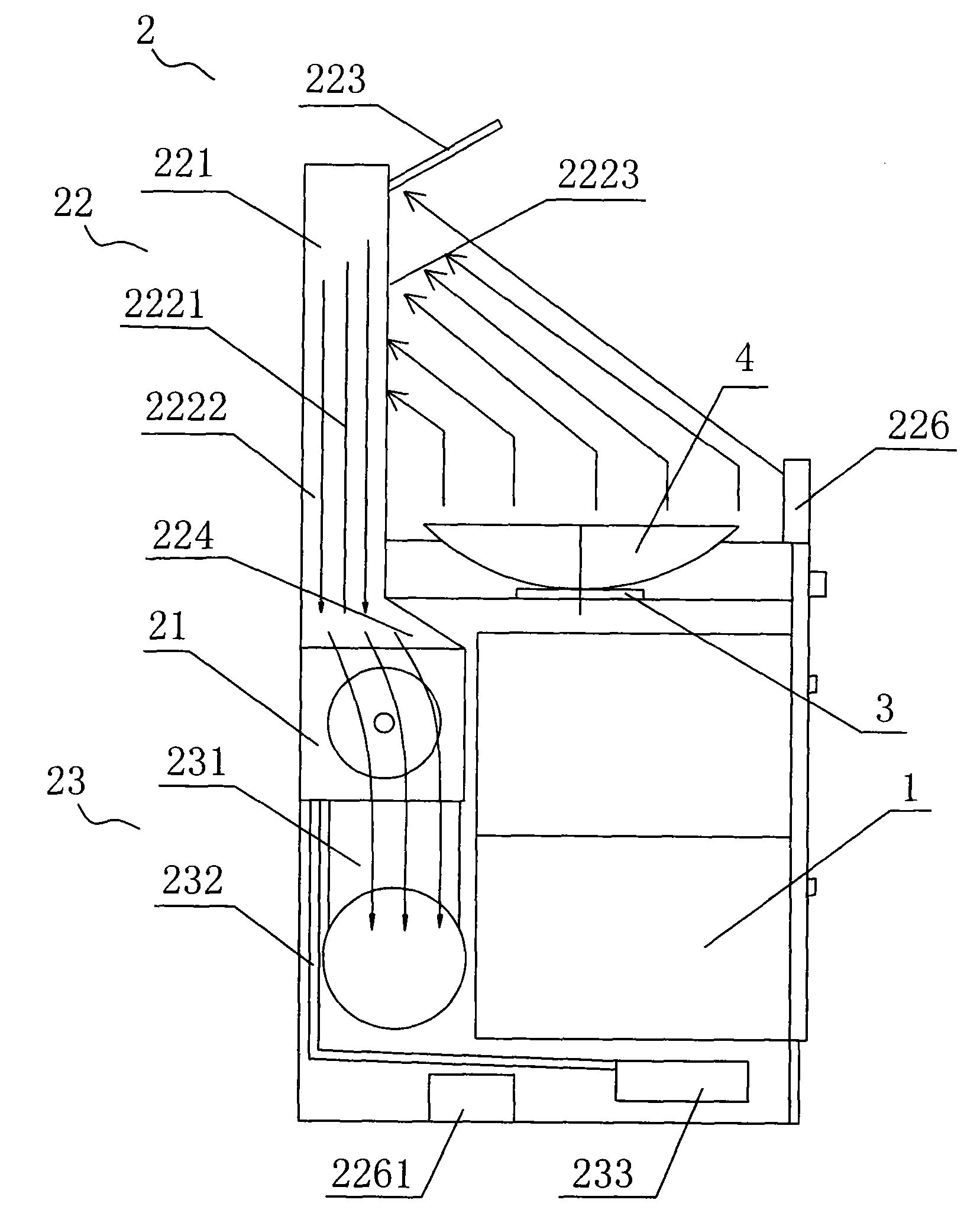

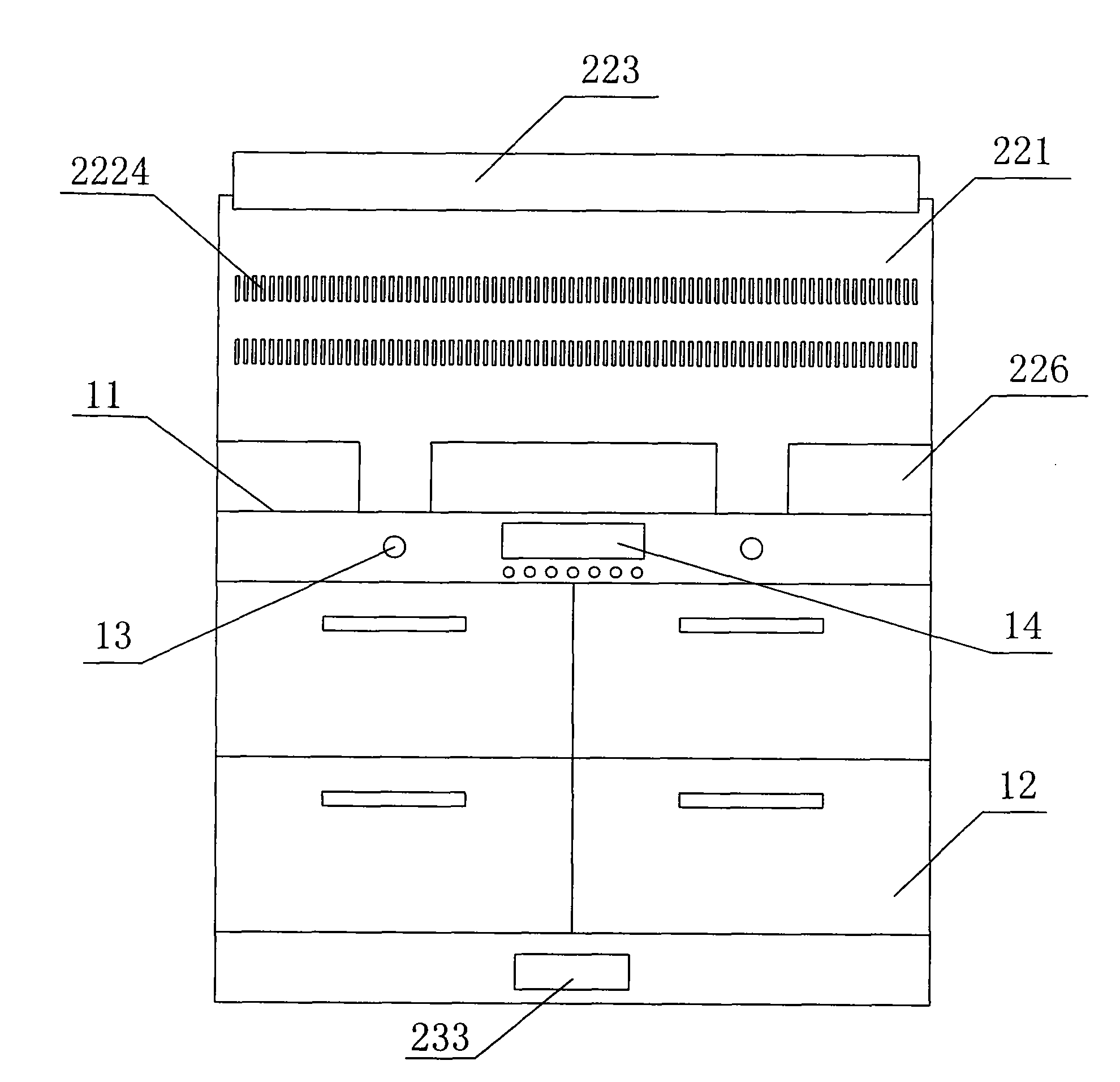

[0090] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0091] See Figure 2 ~ Figure 4 , figure 2 It is a structural schematic diagram of an embodiment of the present invention, image 3 for figure 2 The front structure schematic diagram of the embodiment of the present invention shown, Figure 4 It is an enlarged schematic diagram of a blowpipe according to an embodiment of the present invention. The range hood integrated machine of the present invention includes a body 1, a range hood 2 and a cooker 3 arranged on the body 1, and a locker 12, a gas switch 13 and a display panel 14 are also arranged on the body 1, Commonly used kitchen appliances and kitchen utensils can be placed in the locker 12; Wherein, the oil suction device 22 includes an air guide pipe 221 provided with an air suction port 2223, the air guide pipe 221 is arranged on the rear side of the panel 11 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com