Palladium/carbon/silicon heterojunction material with hydrogen sensitive effect

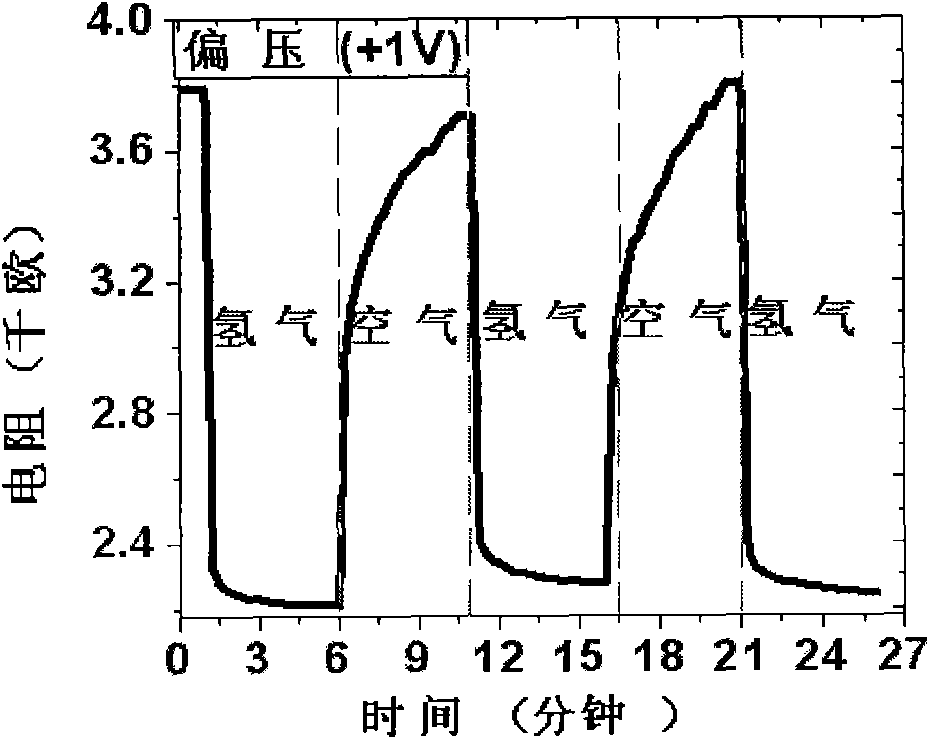

A technology of silicon heterojunction and hydrogen, applied in the direction of material resistance, material capacitance, etc., can solve the problems of complex sensor preparation process, detection of hydrogen, and the electrical characteristics of palladium film/carbon film/silicon heterojunction materials, etc., to achieve High sensitivity, short response time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

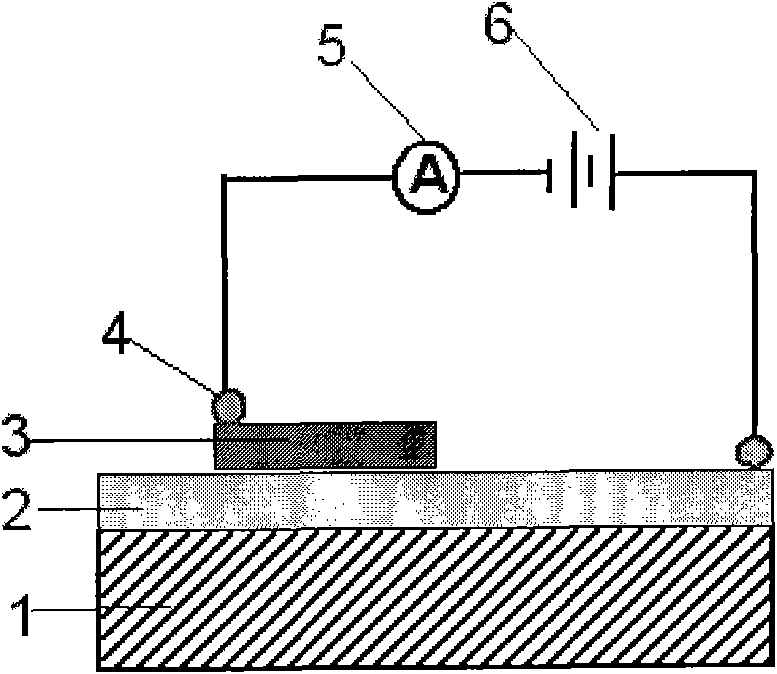

[0022] Example 1, take graphite powder with a mass concentration of 99.9% and make a pure graphite target by cold pressing. Use magnetron sputtering method to sputter pure graphite target to an area of 0.8cm 2 , a thickness of 0.5 to 1.0 mm on a monocrystalline silicon substrate 1, on the monocrystalline silicon substrate, a carbon film 2 with a thickness of about 100 nanometers is formed, and then the mass concentration is 99.9% by magnetron sputtering. % of the palladium target is sputtered onto the carbon film 2, forming a 0.3cm area on the surface of the carbon film 2 2 , a palladium film 3 with a thickness of 20nm, connect a DC power supply 6 on the heterojunction material, such as figure 1 As shown, among the figure 4 is the contact point of power line and material, 5 is an ammeter, becomes the conductivity type hydrogen gas sensor. The preparation parameters of the heterojunction material: ① pure carbon film: the sputtering DC voltage is 0.40 kV, the sputtering DC c...

Embodiment 2

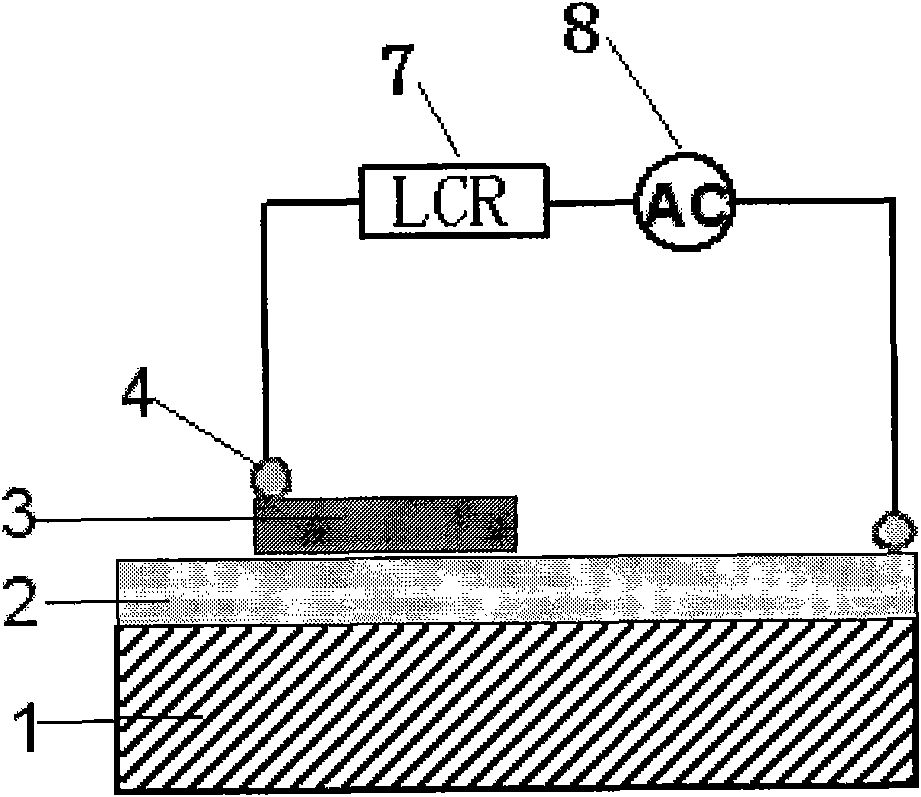

[0024] Example 2, take graphite powder with a purity of 99.9% and make a pure graphite target by cold pressing. Use magnetron sputtering method to sputter pure graphite target to an area of 0.8cm 2 , a thickness of 0.5 to 1.0 mm on a monocrystalline silicon substrate 1, on the monocrystalline silicon substrate, a carbon film 2 with a thickness of about 100 nanometers is formed, and then the mass concentration is 99.9% by magnetron sputtering. % of the palladium target is sputtered onto the carbon film 2, forming a 0.3cm area on the surface of the pure carbon film 2 2 , a palladium film 3 with a thickness of 20nm, such as figure 2 As shown, 8 in the figure is the AC signal loaded by the heterojunction material, 4 is the contact point between the power line and the material, and 7 is the precision LCR digital bridge, which becomes a capacitive hydrogen gas sensor. The preparation parameters of the heterojunction material: ① pure carbon film: the sputtering DC voltage is 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com