Carbon/silicon heterojunction material having NH3 gas sensitizing effect

A silicon heterojunction, gas-sensitive technology, applied in the direction of material resistance, can solve the problems of short life, potential safety hazards, and limited application of gas sensors, and achieve the effects of short response time, good stability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

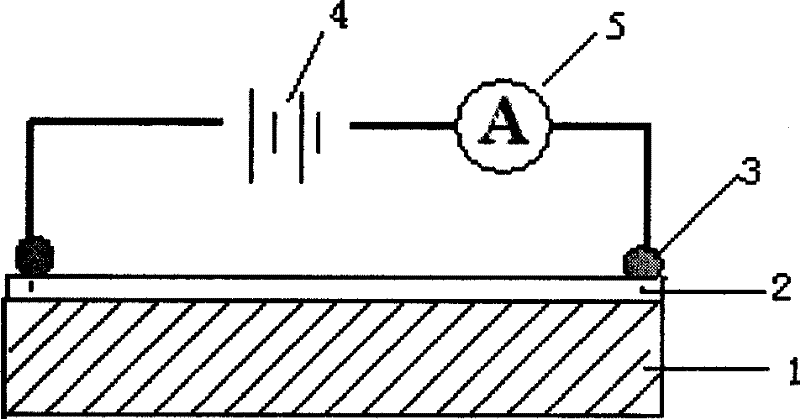

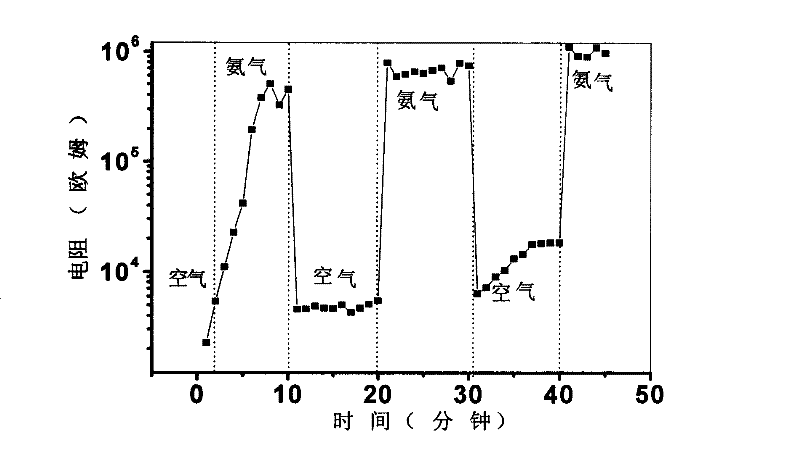

[0017] Embodiment 1, a diamond-like carbon film 2 with a thickness of 100 nm is sputtered on a silicon substrate 1 with a thickness of 1.0 mm by magnetron sputtering, and a DC power supply 4 and an ammeter are connected on the heterojunction material 5, 3 are the contacts between the power line and the material, and become conductive NH 3 Gas sensors such as figure 1 As shown, the purity of the graphite target is 99.9%, the sputtering DC voltage is 0.50KV, the sputtering DC current is 0.10A, the sputtering deposition temperature is 400°C, and the sputtering time is 20 minutes. The sensitivity of the resistance of the sample at room temperature to ammonia and air has been tested, and the test results are as follows: figure 2 shown. The results show that the resistance of the sample in air is about two orders of magnitude smaller than that in ammonia.

Embodiment 2

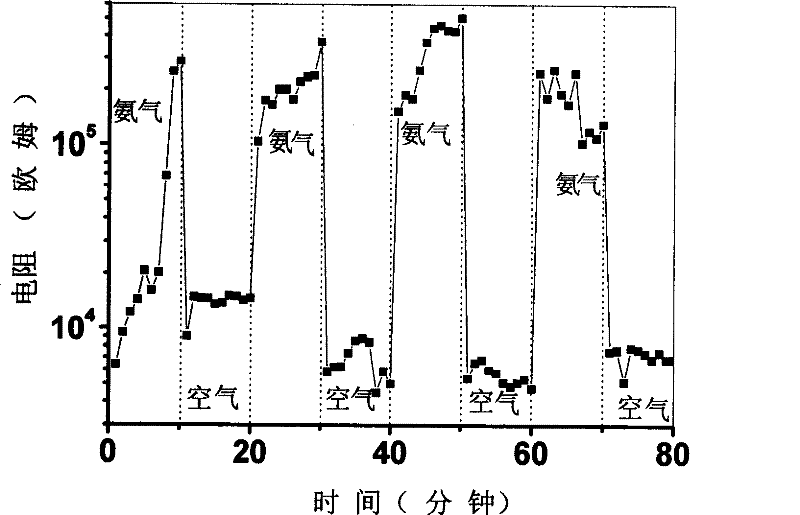

[0018] Example 2, take graphite powder with a purity of 99.9%, add a small amount of iron powder with a purity of 99.9%, and use cold pressing to make an iron-carbon composite target with a mass content of iron of 5%. The iron-carbon composite target is sputtered onto a silicon wafer 1 with a thickness of 1.0 mm by magnetron sputtering, and an iron-doped carbon film 2 with a thickness of 100 nm is formed on the silicon wafer. Turn on the DC power supply 4, 3 is the contact point between the power line and the material, and it becomes a conductive NH 3 Gas sensors such as figure 1 As shown, the sputtering DC voltage is 0.50KV, the sputtering DC current is 0.10A, the sputtering deposition temperature is room temperature, and the sputtering time is 20 minutes. The sensitivity of the resistance of the sample at room temperature to ammonia and air has been tested, and the test results are as follows: image 3 shown. The results show that the resistance of the sample in air is ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com