Dynamical pressure type high-energy synthetic jet actuator

A synthetic jet and exciter technology, applied in the direction of electrical components, plasma, etc., can solve the problems of small jet flux and energy, low air pressure and density, and limited operating frequency of the exciter, so as to improve the operating frequency and Response speed, solving the effect of small jet flow rate and easy integration of control components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

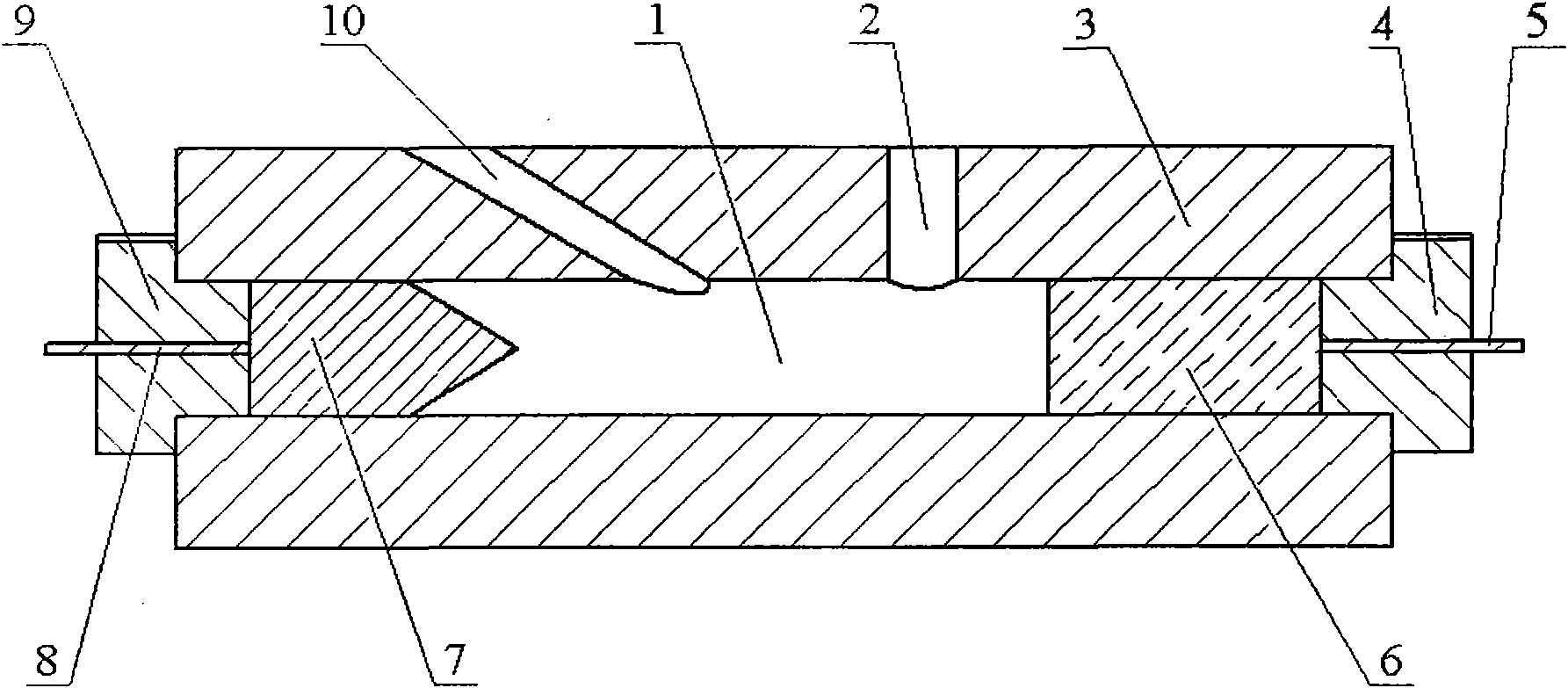

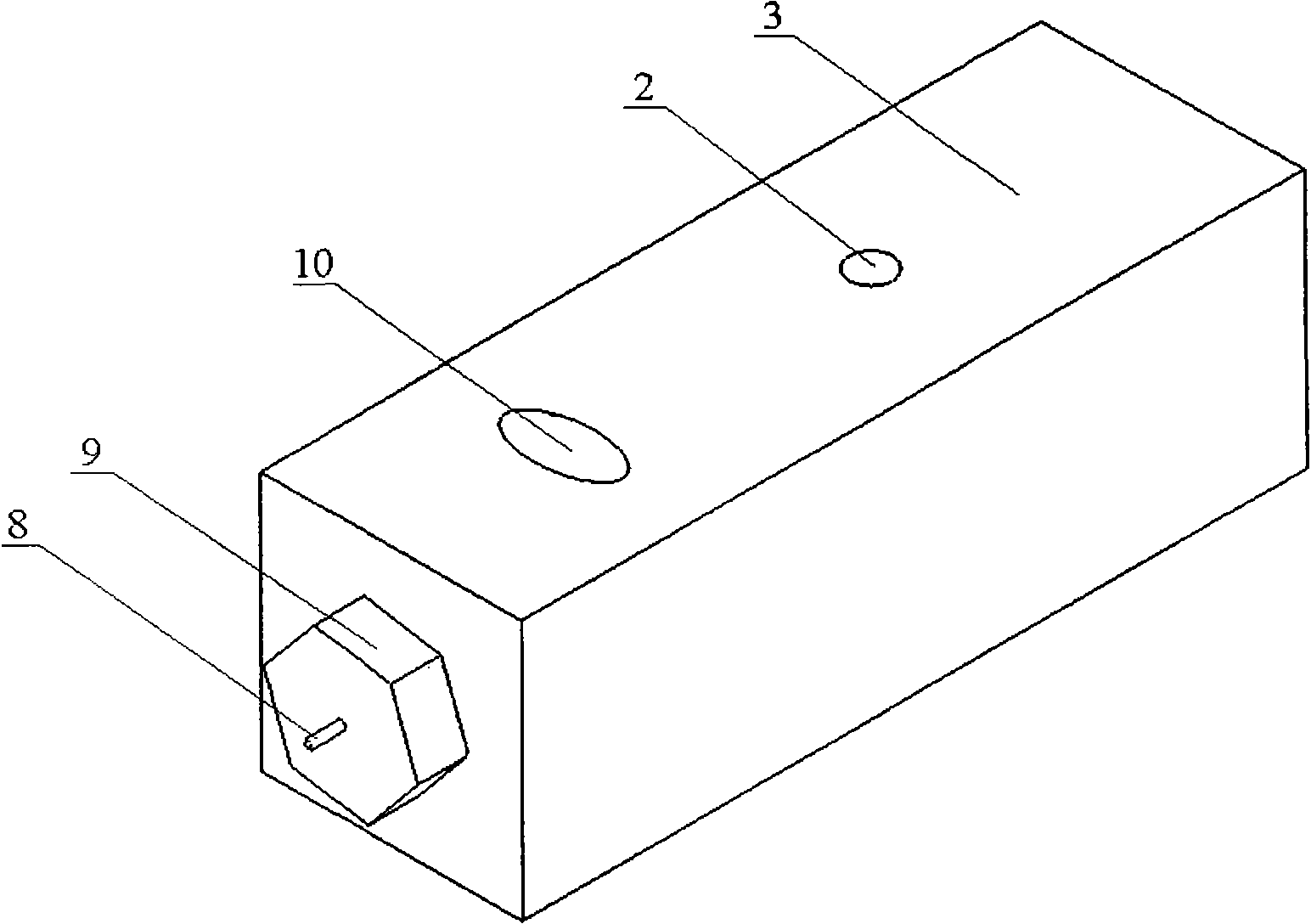

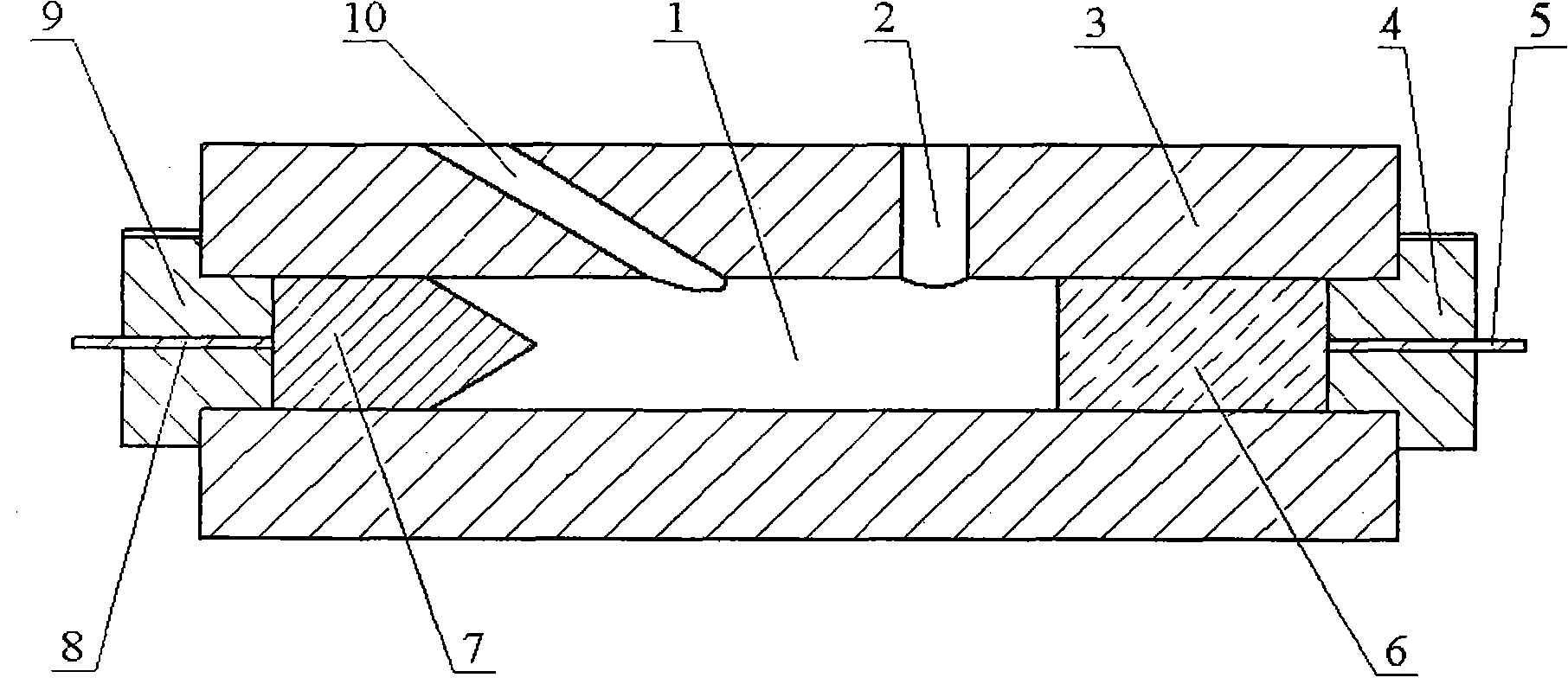

[0027] See attached Figure 1~2 , this embodiment of the dynamic pressure type high-energy synthetic jet exciter of the present invention, in order to accelerate the cooling rate of the housing, the material is made of glass-ceramic plate profiles with a thickness of 2mm, or with a large thermal conductivity. The casing 3 is made of a boron nitride plate profile with a thickness of 2mm. The housing 3 is in the shape of a cuboid with a size of 60×10×10mm 3 . Shell 3 as figure 1 As shown, a dynamic pressure inlet 10 and a jet outlet 2 are provided on both axial sides of its upper bottom surface. Among them, the dynamic pressure inlet 10, in order to increase the flow rate of the intake air flow, is made into a convex oval shape, which is opposite to the external high-speed incoming flow, so that the dynamic pressure of the incoming flow can be efficiently used to increase the flow rate that can be captured; while the jet outlet 2 is round hole shape, in order to increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com