Food product conditioning agent and food product

A quality improver, food technology, applied in food preparation, application, food science and other directions, can solve problems such as unpleasant odor, and achieve the effects of excellent storage stability, improved physical properties, and improved mechanical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The method for preparing the food quality improver of the present invention is not particularly limited, and any method may be used as long as the above-mentioned components can be mixed. Specifically, for example, it can be manufactured by the following method.

[0078] First, the water phase and the oil phase are emulsified with an emulsifier to prepare a W / O emulsion, and the W / O emulsion is added to a water-swelling liquid of a gel-forming substance and stirred to obtain a mixed liquid. Here, when glucomannan is used as the gel-forming substance, it is only necessary to contain an alkaline agent in advance in the water phase forming the W / O emulsion. In addition, the emulsifier used for a W / O type emulsion is not an emulsifier which forms a lamellar structure. In addition, an aqueous dispersion in which a layered structure is formed from organic acid monoglycerides and the like is prepared. When preparing this aqueous dispersion, it is preferable to contain other ...

Embodiment

[0152] Hereinafter, the present invention will be described in more detail by way of examples, but the explanation of the present invention is not limited to the following examples unless the gist of the present invention is exceeded.

[0153] It should be noted that in the following experimental examples, only succinic acid monoglyceride stearate is the emulsifier for forming a lamellar structure in the present invention, and all other emulsifiers are equivalent to other emulsifiers in the present invention .

experiment example 1

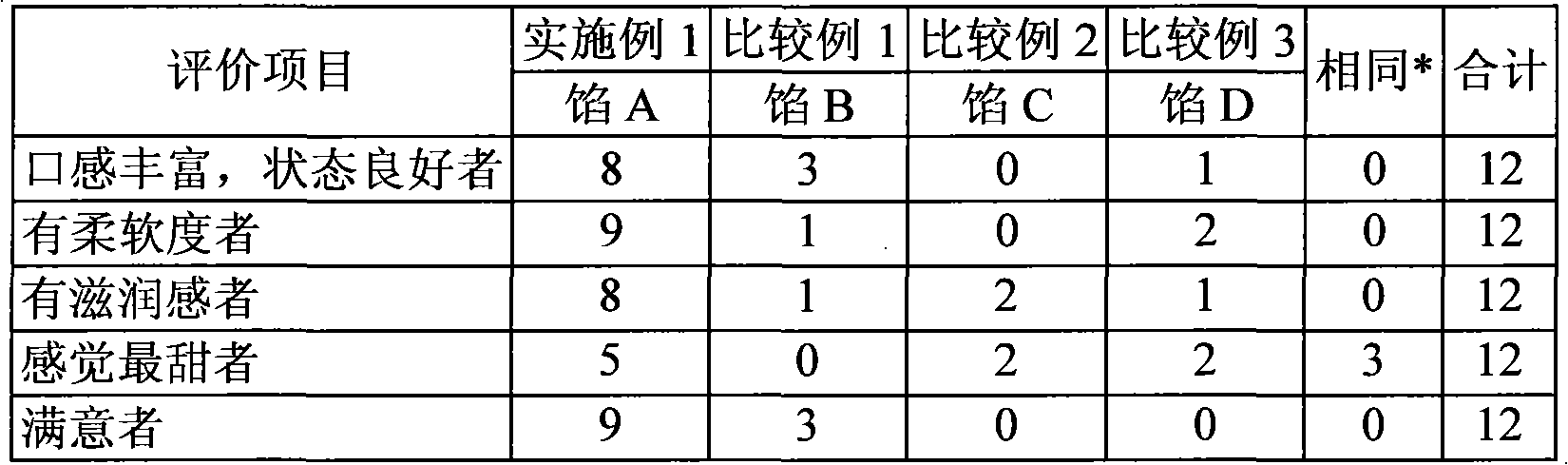

[0154] [Experimental example 1] Evaluation of stuffing

[0155] 1. Preparation of Food Quality Improver A

[0156] 2.1 g of glucomannan ("RHEOLEX RS" manufactured by Shimizu Chemical Co., Ltd.) was swelled in 219.94 g of tap water, and 0.042 g of a fragrance preparation ("Neroli flower water AS-1671" manufactured by Kyowa Fragrance Kosan Co., Ltd.) and ethanol were added. 0.021g, stirred. On the other hand, 25.13 g of lipoprotein (prepared by the following method) was dispersed in 83.77 g of corn oil, and Na 3 PO 4 12H 2 O 4.188g and Na 2 P 2 o 7 0.084 g was dissolved in tap water 86.289 g of the obtained aqueous solution, 0.05 g of VC palmitate ("Bitumin C Parumite" manufactured by Mitsubishi Chemical Foods Co., Ltd.) and polyglyceryl fatty acid ester ("Sunsoft 818SK" manufactured by Sun Chemical Corporation) were added. ") 0.503g, and emulsified at 40°C with a homomixer to prepare a W / O emulsion.

[0157] 8.36 g of this W / O emulsion was mixed with the glucomannan sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com