Structure, method of forming structure, method of laser processing, and method of discriminating between true and false objects

一种结构体、激光的技术,应用在激光焊接设备、金属加工设备、化学仪器和方法等方向,能够解决成本增加、成本升高、作业烦杂等问题,达到简化作业工序、抑制成本提高、提高吸收率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

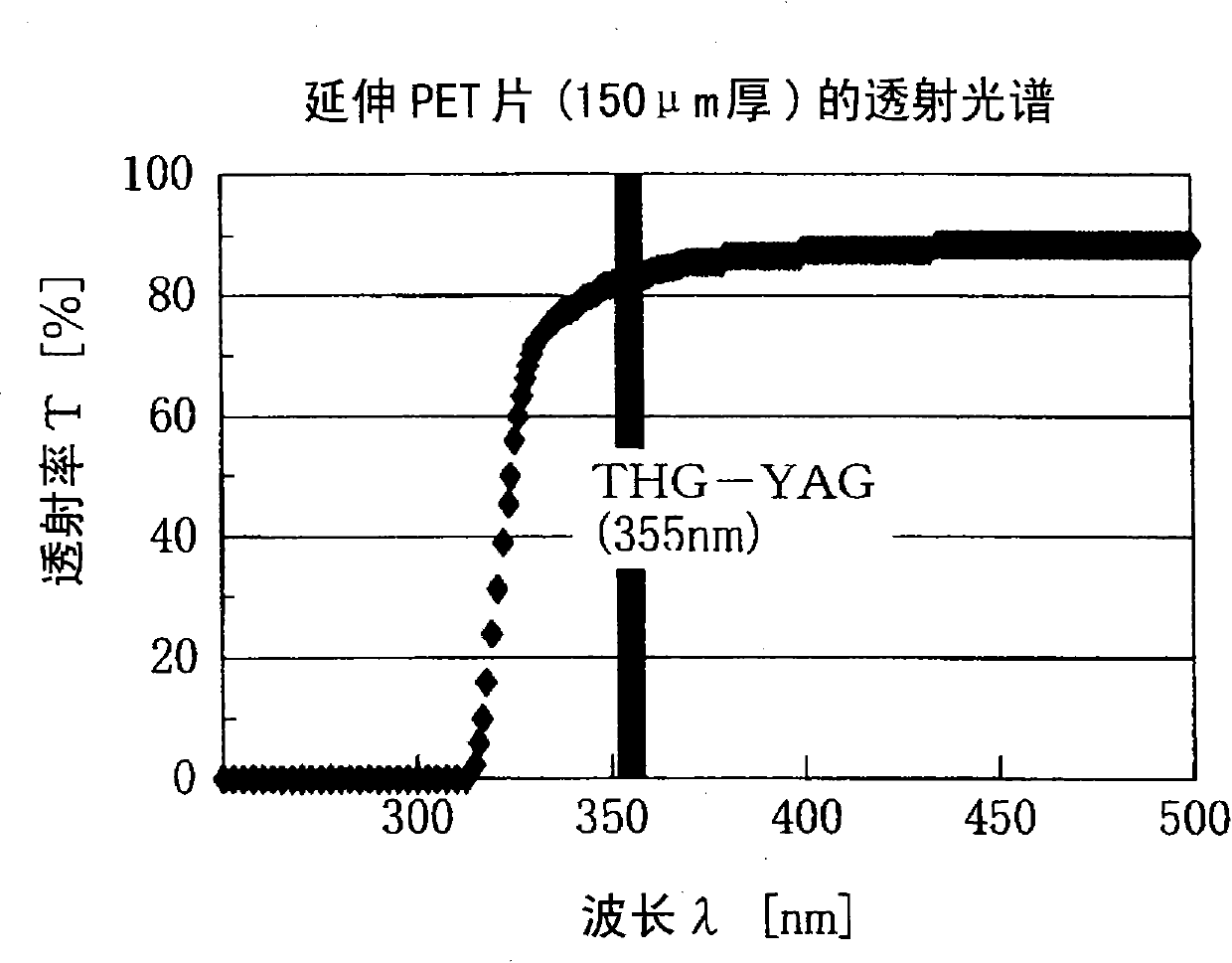

[0228] A plurality of stretched PET sheets having a thickness of 150 μm were prepared as the workpiece 10 d.

[0229] One or more of the stretched PET sheets were irradiated with ultraviolet light from a mercury xenon lamp (Ushio Denki) for 10 minutes at a distance of 12 cm.

[0230] Here, as a result of measuring the transmittance of the stretched PET sheet with respect to a wavelength of 355 nm, it was 82.3% before irradiation and 76.7% after irradiation.

[0231] Next, the stretched PET sheet after UV irradiation and the unirradiated stretched PET sheet were prepared, and the Q-switched pulsed YAG laser third harmonic (wavelength 355 nm) exhibiting transmittance in the stretched PET sheet was irradiated with a laser irradiation device.

[0232] Here, the specifications of the pulsed YAG laser are a pulse width of 5 ns and a repetition rate of 10 Hz. In addition, the irradiation energy density is 400 [mJ / cm 2 ], one pulse is irradiated, and the irradiated energy density is...

Embodiment 2

[0238] A plurality of stretched PET sheets with a thickness of 150 μm were prepared as the workpiece 10 d.

[0239] One or more of these stretched PET sheets were irradiated with ultraviolet light emitted from a mercury xenon lamp (Ushio Denki) at a distance of 55 mm for 5 seconds.

[0240] Here, as a result of measuring the transmittance of the stretched PET sheet with respect to a wavelength of 355 nm, it was 82.3% before irradiation and 82.1% after irradiation.

[0241] Next, prepare the stretched PET sheet after UV irradiation and the stretched PET sheet that has not been irradiated, and irradiate the stretched PET sheet with the Q-switched pulsed YAG laser third harmonic that exhibits transmittance using an interference optical system (laser irradiation device 20). (wavelength 355nm).

[0242] Here, the specifications of the pulsed YAG laser are a pulse width of 5 ns and a repetition rate of 10 Hz. In addition, the irradiation energy density is 400 [mJ / cm 2 ] to emit a...

Embodiment 3

[0246] Four stretched PET sheets with a thickness of 150 μm were prepared as the workpiece 10 d.

[0247] One of these stretched PET sheets was irradiated with a UV lamp (black light) having an emission peak wavelength of 254 nm for 90 minutes. In addition, another sheet was irradiated with a 302 nm UV lamp for the same period of time. Furthermore, another sheet was irradiated with a 365 nm UV lamp for the same period of time. And, the UV lamp was not irradiated to the remaining stretched PET sheet.

[0248] Here, the transmittance of the stretched PET sheet with respect to a wavelength of 355nm was 82.3% without irradiation, 80.4% after irradiation at 254nm, 77.9% after irradiation at 302nm, and 81.8% after irradiation at 365nm.

[0249] Next, the above-mentioned four stretched PET sheets were irradiated with the third harmonic of YAG laser (wavelength: 355 nm) by a laser irradiation device.

[0250] Each PET sheet irradiated with UV of each peak wavelength was irradiated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com