New comprehensive impurity removing process and system for reconstituted tobacco raw material extract

A technology of tobacco flakes and extracts, which is applied in the fields of tobacco, tobacco treatment, application, etc., can solve the problem of no tobacco flake raw material adsorption clarifying agent, etc., and achieve the effects of improving mechanical sedimentation efficiency, improving miscellaneous gas and aftertaste, and good product aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

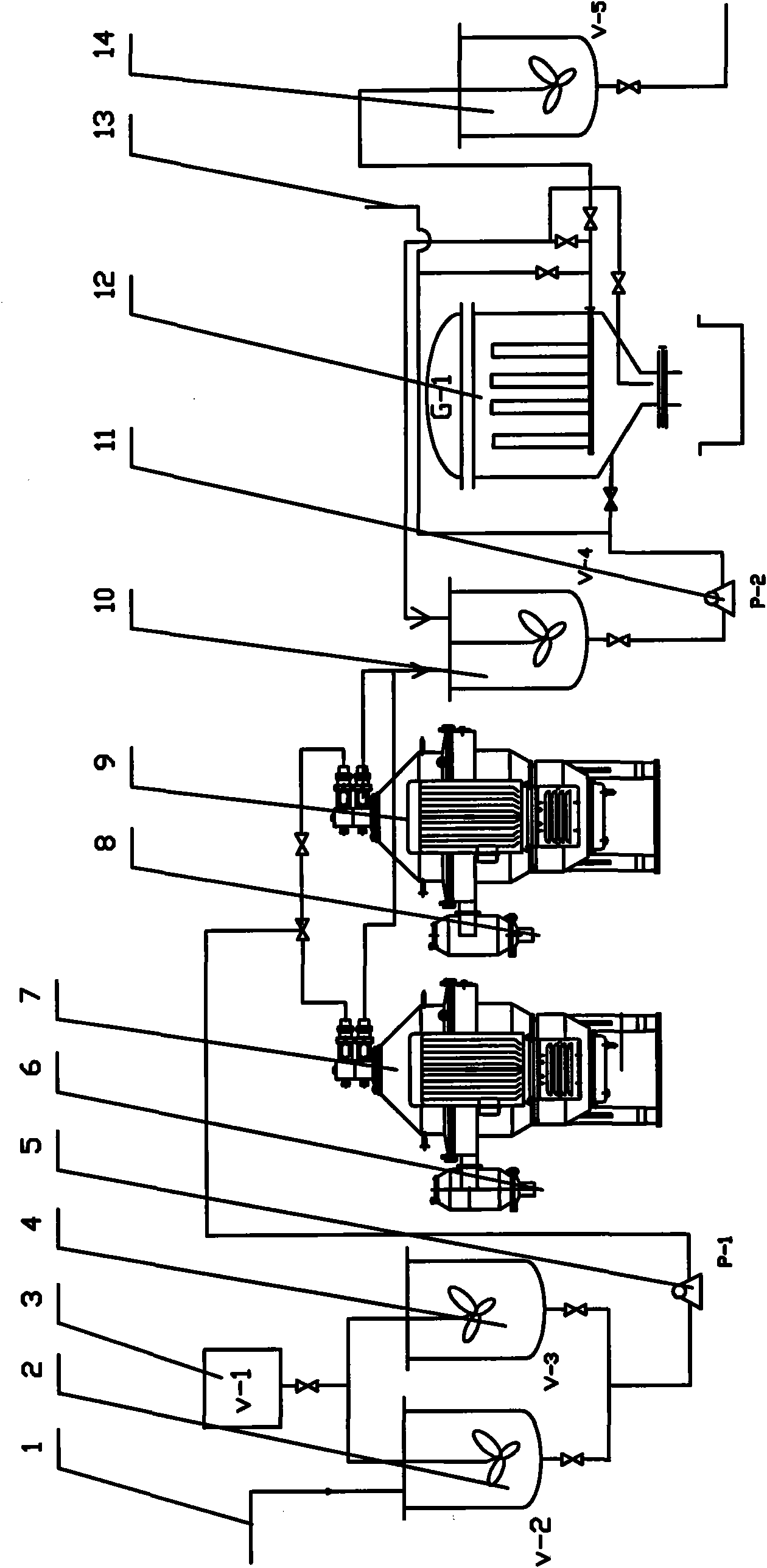

[0022] The specific implementation manners and related technical problems of the present invention will be further described in detail below in conjunction with the accompanying drawings. For brevity, the process and system are described together below. as attached figure 1 As shown, the material that needs to be removed is fed into the flocculation tanks 2 and 4 through the material pipeline 1 of the stalk and the final extract, and the adsorption clarifier tank 3 is arranged on the upper part of the flocculation tank 2 and 4, and the adsorption clarifier There are pipelines at the bottom of the tank 3 connected to the flocculation tanks 2 and 4. The adsorption clarifier tank 3 can add the special adsorption clarifier to the flocculation tanks 2 and 4 through the pipeline, and stir and keep warm in the flocculation tanks 2 and 4 for flocculation Reaction (so-called flocculation is also called adsorption clarification), the special adsorption clarifier for impurity removal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com