Raspberry-like polystyrene microsphere/silicon dioxide composite particles and preparation method and use thereof

A technology of polystyrene microspheres and silicon dioxide, which is applied in the preparation of microspheres and microcapsule preparations, and can solve the problems that it is difficult to obtain composite particles with regular structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1. carry out oxygen plasma treatment to polystyrene microsphere surface

[0034] Select commercially available polystyrene microspheres (solid powder state) with a particle size of 50-200nm, 200-500nm and 500-800nm as the core to prepare raspberry-shaped polystyrene microspheres (core) / dioxide Silicon (shell) organic-inorganic composite particles.

[0035] The specific process of oxygen plasma treatment is: after grinding the above-mentioned commercially available polystyrene microsphere solid powder, transfer it to the sample chamber of the plasma cleaner (Chengdu Mingheng Technology Development Co., Ltd.), and evacuate the sample chamber through a vacuum pump. , make the pressure difference between the sample chamber and the sample chamber be -1~-0.1MPa, then pass oxygen into the sample chamber through the gas flow meter, and keep the gas flow rate at 600~1000mL / min. Continue to evacuate the sample chamber through the vacuum pump. When the air pressure i...

Embodiment 2

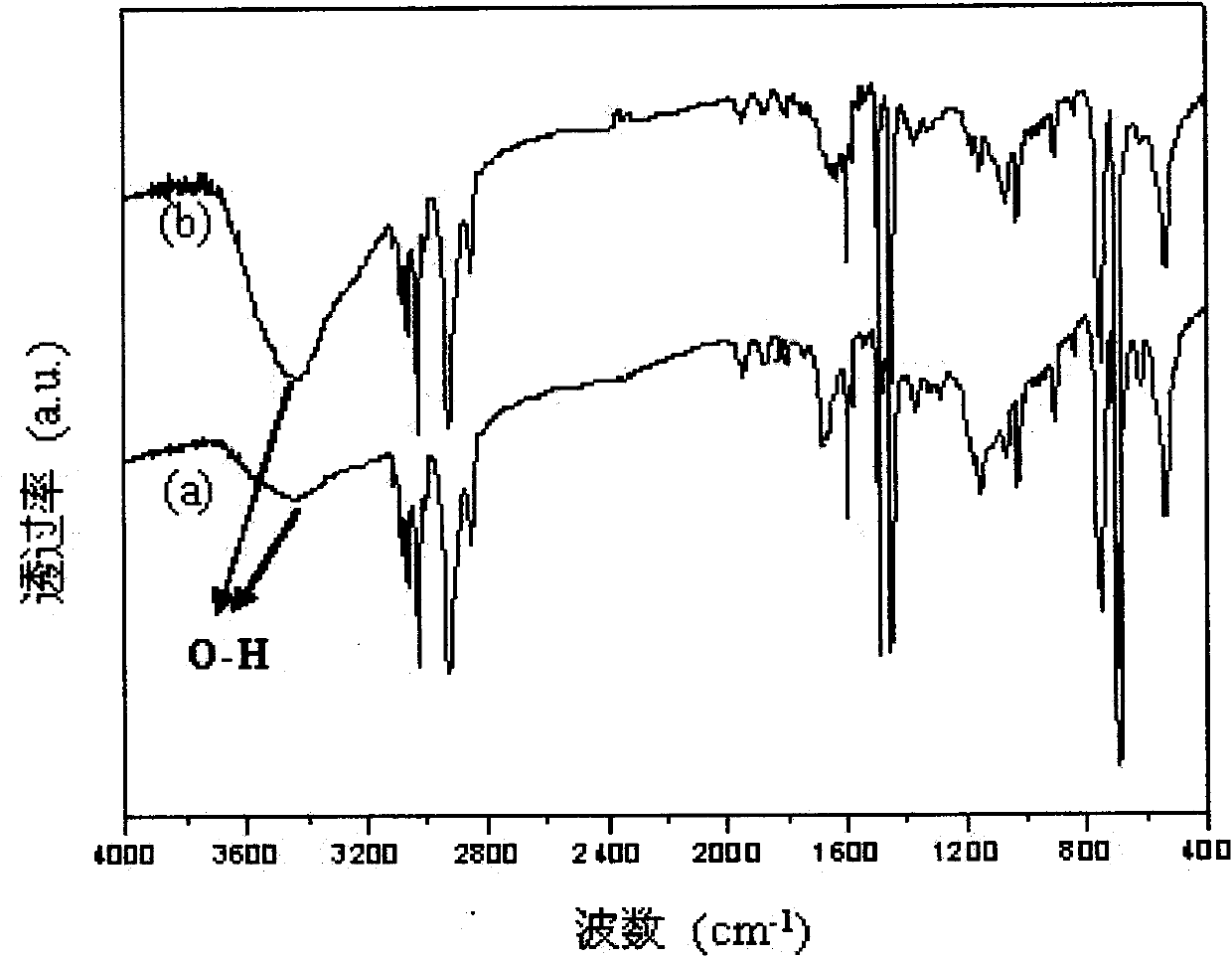

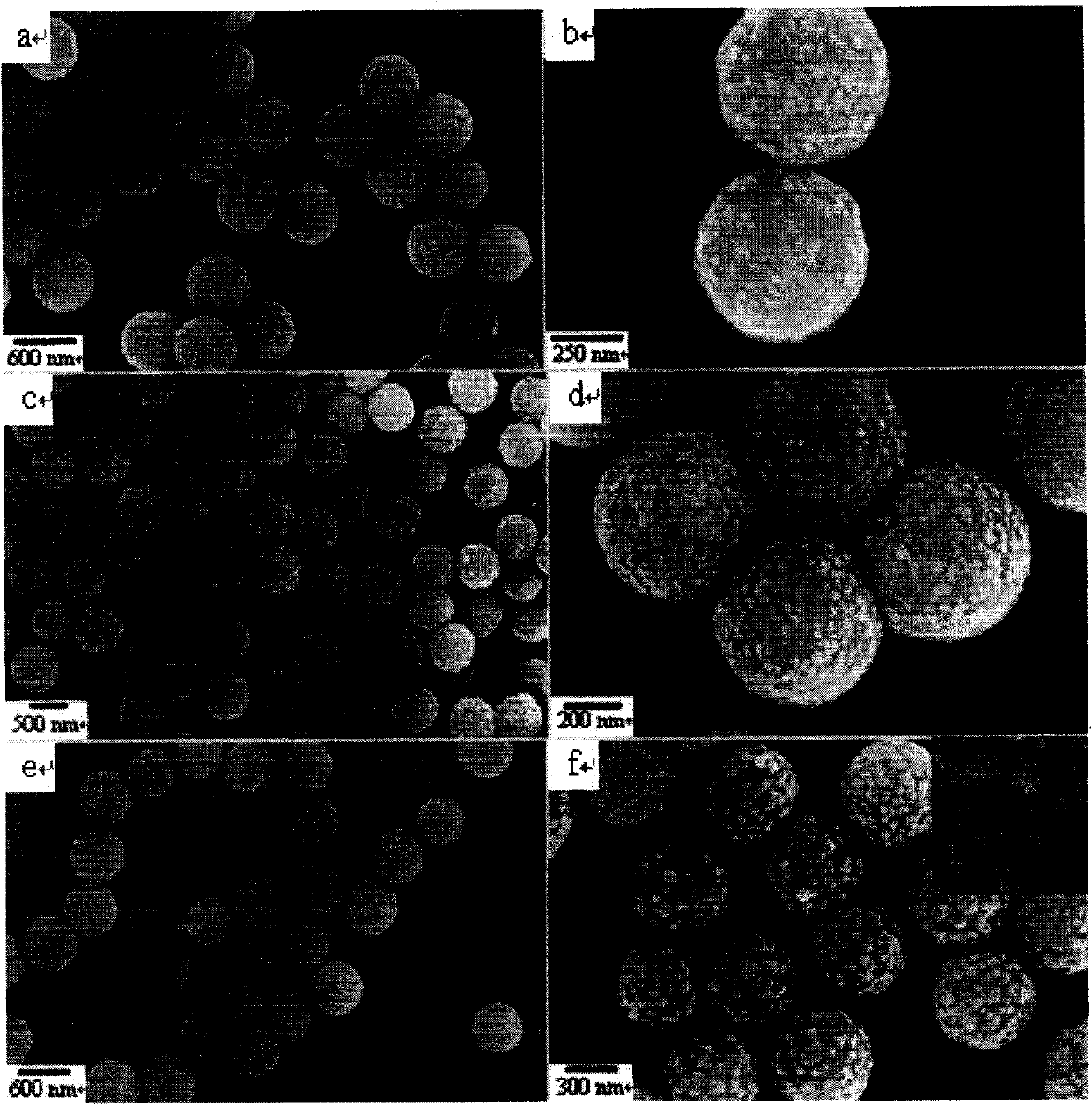

[0036] Example 2. Preparation of raspberry-shaped polystyrene microspheres (core) / silicon dioxide (shell) organic-inorganic composite particles

[0037] Put 0.5~1.5g of polystyrene microspheres with a particle size of 50~200nm, 200~500nm and 500~800nm through the oxygen plasma treatment in Example 1 respectively into a 150mL conical flask equipped with 100mL absolute ethanol middle; put the container loaded with the polystyrene microspheres into an ultrasonic cleaner, and the polystyrene microspheres were ultrasonically treated in the ultrasonic cleaner for 10 to 30 minutes at a power of 80 to 120W to obtain a suspension; When the above-mentioned suspension was subjected to slow electromagnetic stirring (30-60 rpm) respectively, 3-6 mL of ammonia water (concentration was 25-28 wt%) was added respectively; slow electromagnetic stirring (30-60 rpm) was carried out for 10 to After 30 minutes, carry out strong electromagnetic stirring (120-180 rpm), and add tetraethoxysilane to ...

Embodiment 3

[0042] Embodiment 3. the application of raspberry shape polystyrene microsphere (core) / silicon dioxide (shell) organic-inorganic composite particle

[0043] Utilize the polystyrene microspheres of 50~200nm and 200~500nm respectively in the particle size of oxygen plasma treatment in embodiment 1 as core, the raspberry shape polystyrene microsphere (core) prepared in embodiment 2 / Silica (shell) organic-inorganic composite particles are used as building blocks and the electrostatic layered self-assembly method is used to prepare porous silica hollow sphere coatings on the glass surface. The schematic diagram of the preparation process is as follows Figure 7 shown. The specific process is as follows: First, the newly synthesized and undried raspberry-shaped polystyrene microspheres (core) / silica (shell) organic-inorganic composite particles are dispersed in ultrapure water, and cleaned in an ultrasonic cleaner. Sonicate for 30 minutes at medium 100W power. Secondly, the glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com