Seawater desalination system

A seawater and brine technology, applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve the problems of high energy, low cost, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure, features and embodiments of the present invention are described below by illustrations, so that the present invention can be further understood.

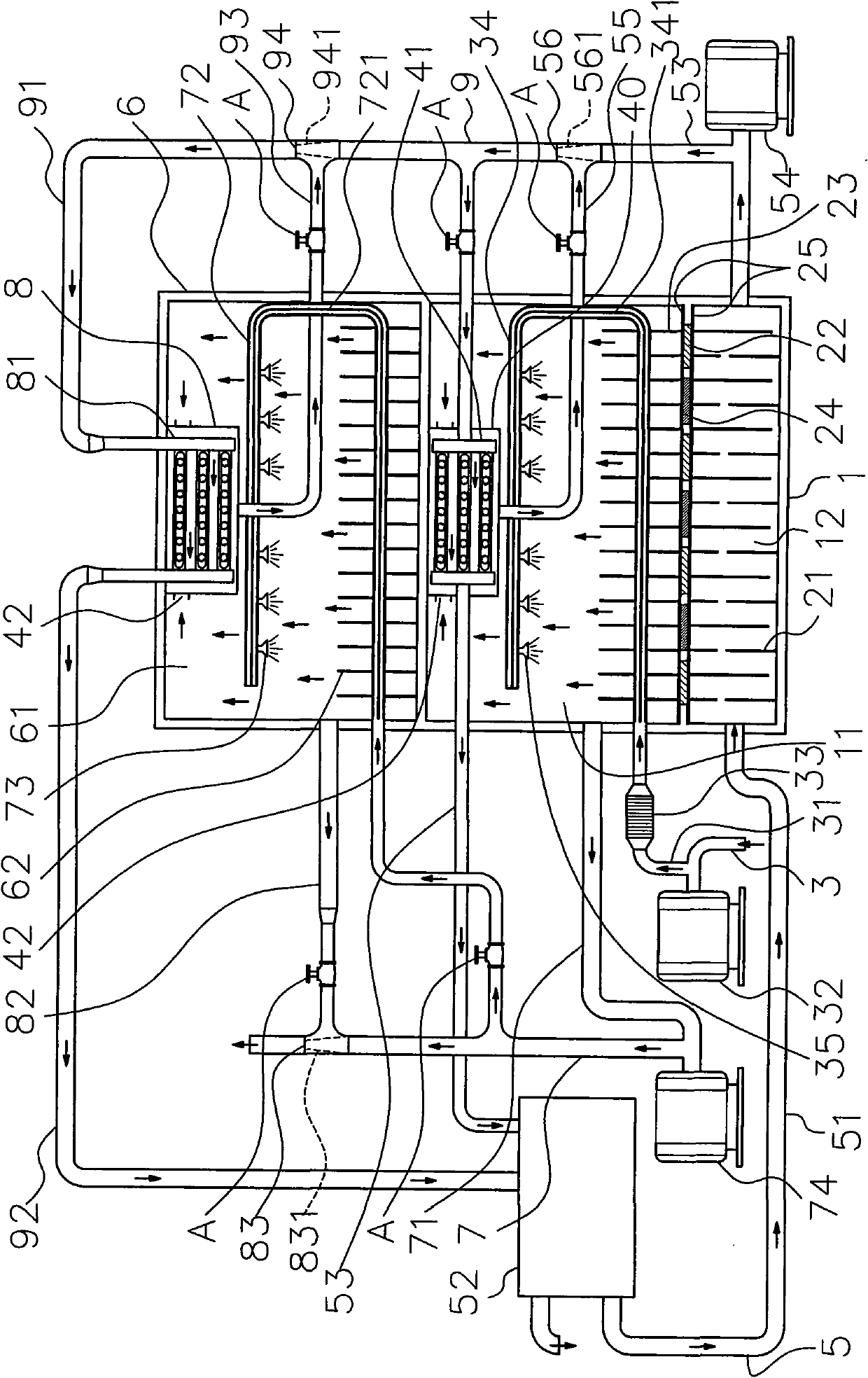

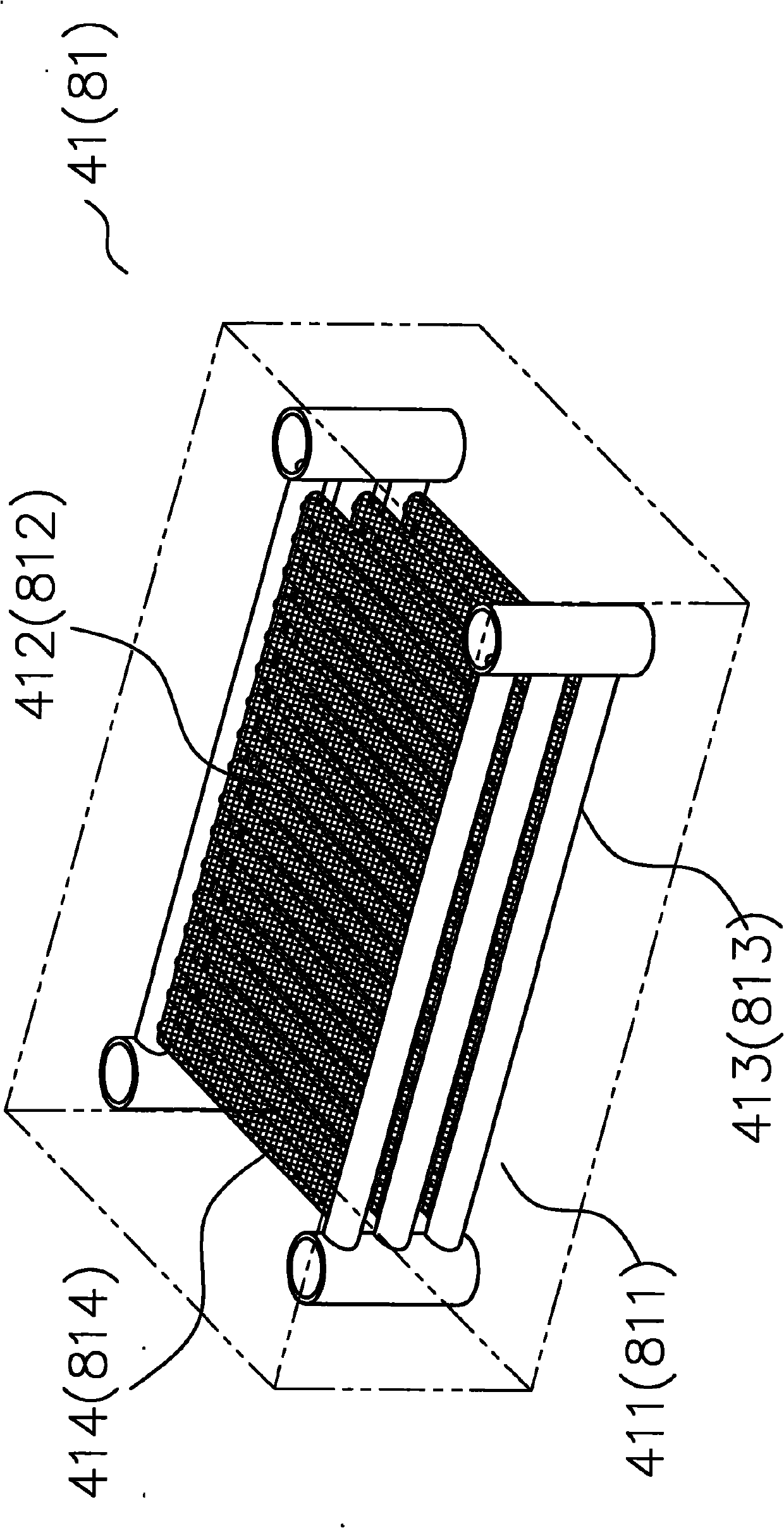

[0031] see figure 1 shown, with Figure 4 , Figure 5 and Image 6 As shown, a seawater desalination system includes an evaporation mechanism 2 and a condensation mechanism 4 communicated with the evaporation mechanism 2, wherein:

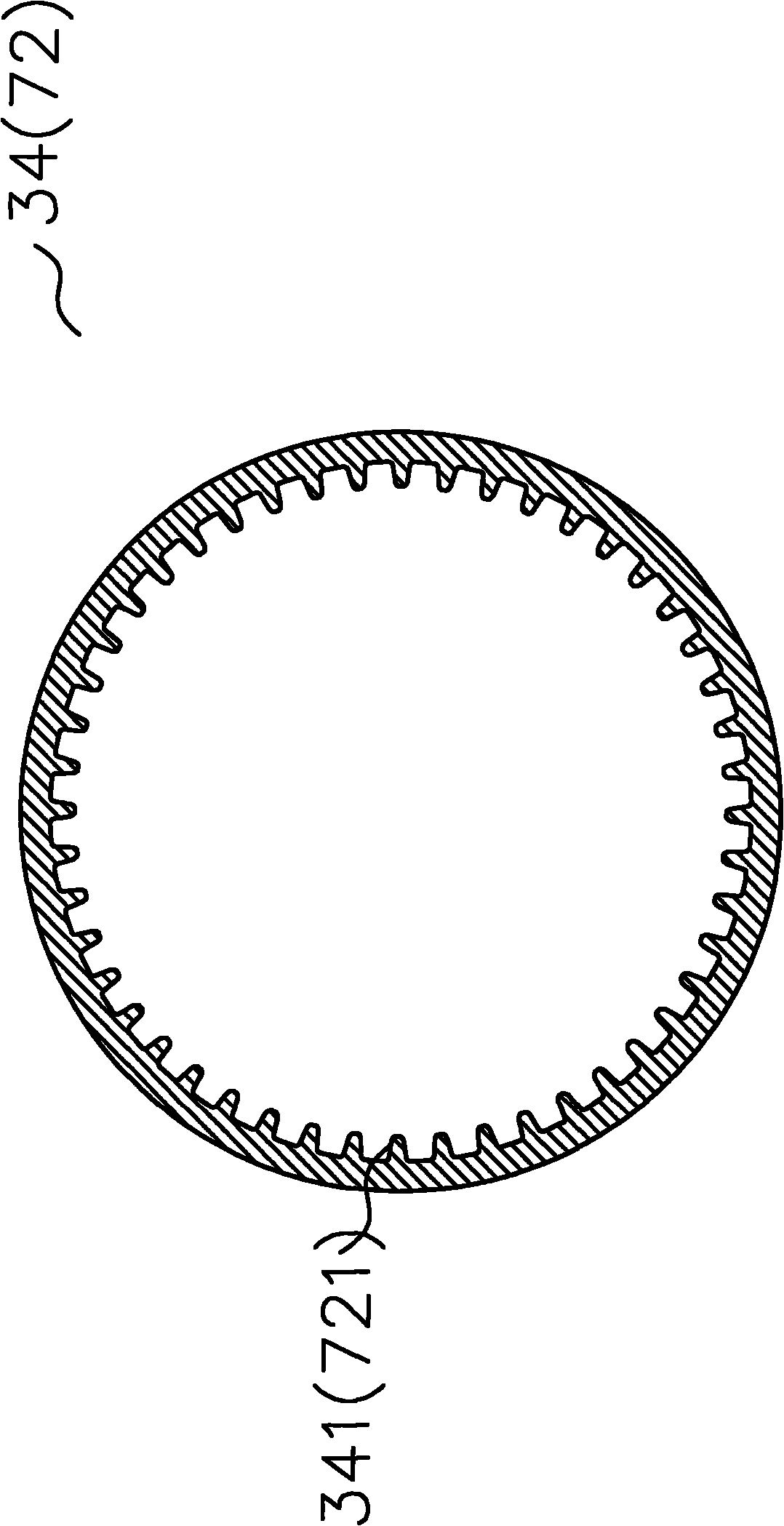

[0032] The evaporation mechanism 2 includes two conductors 25 arranged at intervals, and the intervals between the two conductors 25 are alternately provided with thermoelectric cooling chips 22 and thermoelectric power generation chips 24 at intervals. The thermoelectric cooling chips 22 have a cold surface and a hot surface. , and the cold and hot surfaces of the thermoelectric cooling chip 22 and the top and bottom surfaces of the thermoelectric power generation chip 24 are respectively attached to the two conductors 25, and the temperature generated by the cold and hot surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com