Chemical vapor deposition technology and vapor deposition furnace for preparing pyrolytic boron nitride (PBN) products

A technology for chemical vapor deposition and boron nitride products, which is applied in the field of chemical vapor deposition (CVD) to achieve the effects of improving production efficiency, improving qualification rate and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Single product with three concentric circles, multi-channel air intake, PBN crucible for in-situ synthesis (LEC method), diameter Φ300mm×245mm:

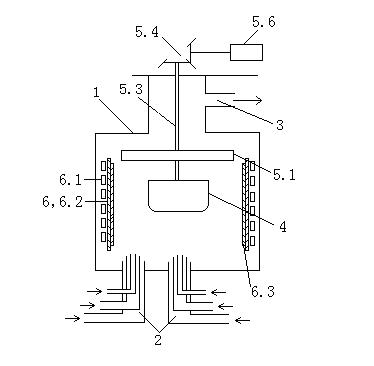

[0029] like figure 1 As shown, the motor 5.6 is connected with the turntable 5.1 through the bevel gear set 5.4, a mold is hung under the turntable 5.1, and the air inlet 2 is a multi-channel three concentric circle air inlet.

[0030] Preparation: Hang the processed graphite mold in the furnace, conduct electricity to raise the temperature, keep the temperature at 2000°C, and ventilate according to the molar ratio of the following gases: N 2 : NH 3 :BCl 3 =48:8:4.8, where N 2 6 L / min, NH 3 1 L / min, BCl 3 0.6 L / min. The pressure in the furnace is 3 Torr, and the holding time is 24 hours. After power-on, the furnace is cooled to room temperature, and the white hard shell deposited on the mold is removed to form a complete PBN crucible blank, which is then machined into a qualified size to obtain a qualified PBN product. ...

Embodiment 2

[0037] 2 products, three concentric circles with multi-channel air intake, the preparation of PBN crucibles for VGF method, diameter Φ25mm×30mm, 2 pieces in one furnace.

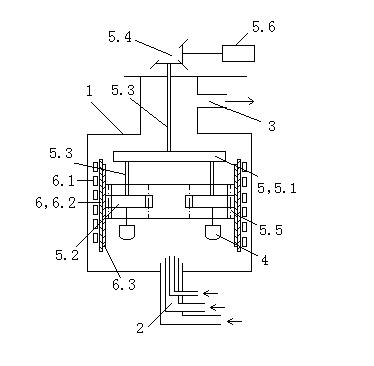

[0038] like figure 2 As shown, the motor 5.6 is connected with the turntable 5.1 through the bevel gear set 5.4, and the two gears 5.2 are fixed under the turntable 5.1 through the connecting shaft, and a mold 4 is hung under each gear. Gear sleeve 5.5 rests on graphite sleeve 6.3 and meshes with all gears 5.2. Air inlet 2 is three concentric circular air inlets.

[0039] Preparation: Cover the furnace cover and start to heat up. After the temperature reaches 1900°C, turn on the motor 5.6 to make the gear 5.2 rotate in revolution and rotation under the action of the motor 5.6, and the revolution speed is 5 revolutions / minute. Raw material gas is introduced into the gas inlet 2 in the following molar ratio: N 2 : NH 3 :BCl 3 =12:1.2:1.0, the pressure in the furnace is 2 torr, the power is cut off after ...

Embodiment 3

[0042] 5 products with three concentric circles and multi-channel air intake, PBN crucibles for MBE method, diameter Φ22×120mm, 5 pieces in one furnace.

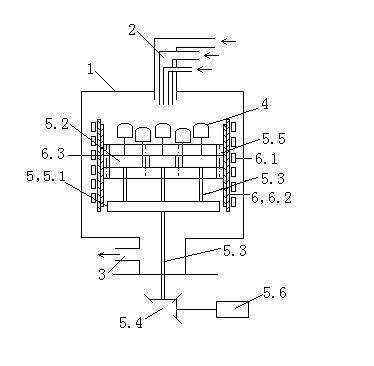

[0043] like image 3 As shown, the motor 5.6 is connected with the turntable 5.1 through the bevel gear set 5.4, and the five gears 5.2 are fixed on the turntable 5.1 through the connecting shaft, and a mold 4 is erected on each gear. The tooth sleeve 5.5 is placed on the graphite sleeve and meshes with all the gears 5.2. Air inlet 2 is three concentric circular air inlets.

[0044] Preparation: Cover the furnace cover and start to heat up. After the temperature reaches 1900°C, turn on the motor 5.6 to make the gear 5.2 rotate in revolution and rotation under the action of the motor 5.6, and the revolution speed is 3 revolutions / minute. Raw material gas is introduced into the gas inlet 2 in the following molar ratio: N 2 : NH 3 :BCl 3 =12:1.2:1.0, the pressure in the furnace is 2 torr, and the power is cut off after 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com