Method for performing quantitative analysis on SiGe thin film by using energy-dispersive X-ray spectroscopy

A quantitative analysis and characteristic spectrum technology, applied in the direction of material analysis using radiation, material analysis using wave/particle radiation, material analysis, etc., can solve the problems of expensive SIMS machines, surge in process costs, high measurement costs, etc., to achieve the analysis cycle Short, operable, and low analysis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0026] On the basis of the existing TEM (transmission electron microscope) / EDS (X-ray dispersive spectrometer), the present invention develops a set of quantitative analysis methods for SiGe component analysis, partially replacing the original SIMS analysis method. This method is to fill in the technical gaps of the SiGe thin film project and the quantitative analysis of materials by X-ray characteristic spectrum. The method specifically includes the following steps:

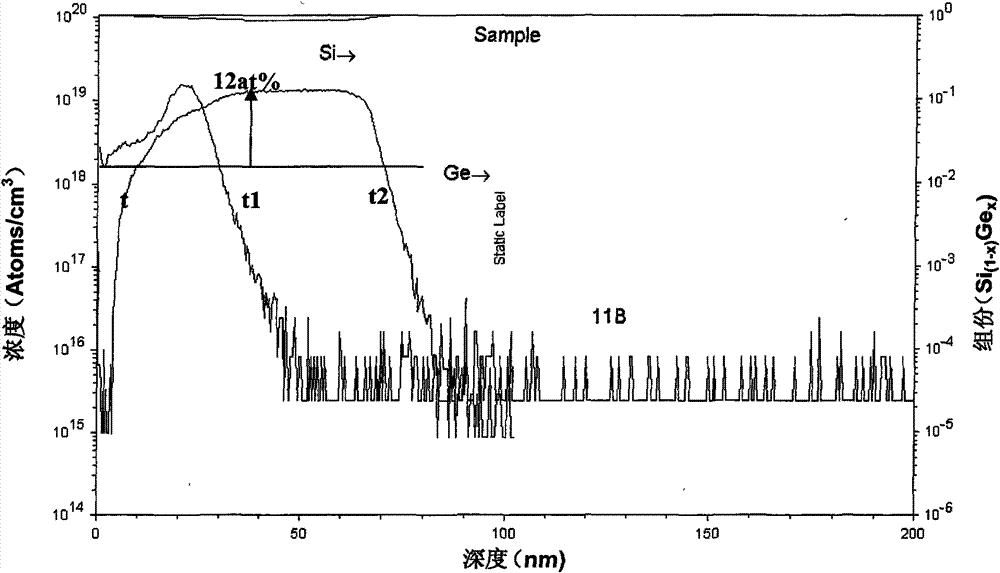

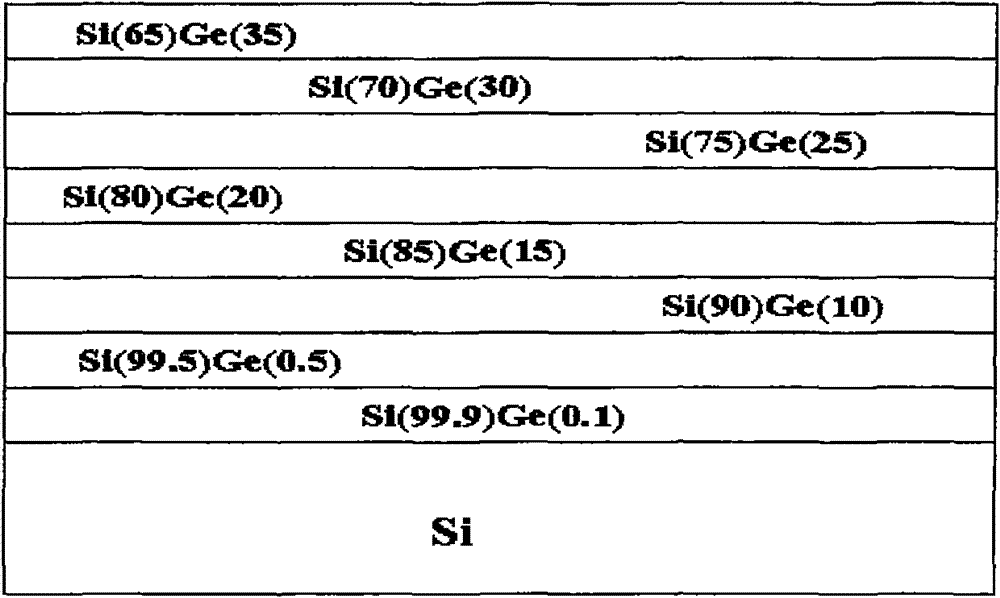

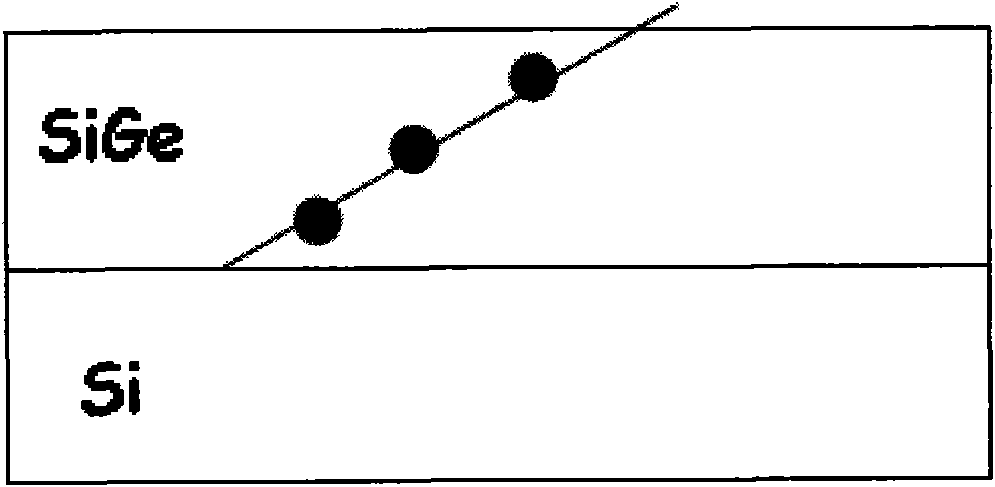

[0027] (1) Use CVD (Chemical Vapor Deposition) SiGe standard multilayer gradient film as a standard sample, and use its SIMS data as the standard composition (atomic percent, at%; or weight percent wt%), the method is in the thickness range of SiGe Take 20 points of equal thickness inside, and find out the corresponding atomic percentage of Ge and Si, see figure 1 ;

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com