Phosphates in the form of suspensions of lanthanum and at least one rare earth element selected from cerium and terbium, process for their preparation and use as luminophores

一种稀土元素、磷酸盐的技术,应用在磷酸盐领域,能够解决难以研磨产物、不可能获得尺寸等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The above description relates to the preparation of phosphate salts in the form of suspensions. To obtain the phosphate salts of the invention in powder form, starting from this suspension, the solid product is separated from the liquid phase using any known separation technique, such as filtration. The solid product thus obtained can optionally be dried and then resuspended in a liquid phase of the same type as described above.

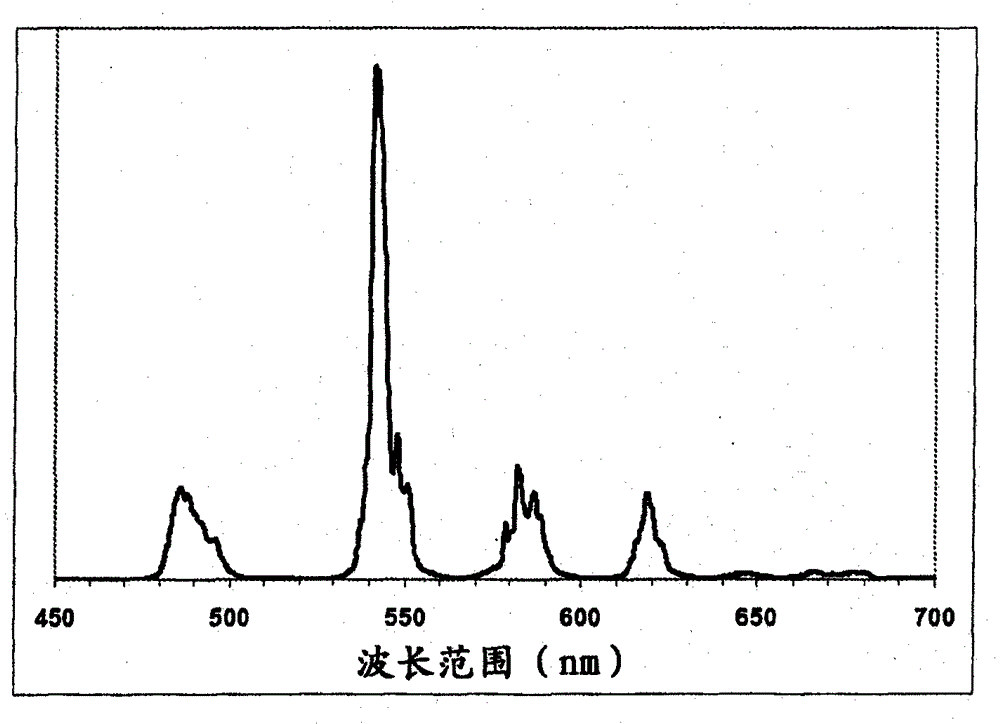

[0085] Due to the nature of the phosphates according to the invention (meaning phosphates in suspension or in solid form) they can be used as emitters. Wavelengths used in plasma systems (screens and lamps where excitation is produced by a noble gas or mixture of noble gases such as xenon and / or neon) and mercury vapor lamps (in the case of phosphate doped with a combination of cerium and terbium) Under electromagnetic excitation in the range, these phosphates have luminescent properties. They can therefore be used as illuminants in plasma s...

Embodiment 1

[0107] This example relates to the formula La according to the invention 0.56 Ce 0.3 Tb 0.14 PO 4 Preparation of a suspension of lanthanum cerium terbium phosphate.

[0108] A solution was composed by mixing lanthanum nitrate, cerium nitrate and terbium nitrate of the following composition (atomic %):

[0109] La: 56%

[0110] Ce: 30%

[0111] Tb: 14%

[0112] The nitrate concentration of the solution was 350 g / l.

[0113] The solution was added to the phosphoric acid solution at 60°C, and its pH value was controlled at 1.6 by adding ammonia water. The phosphate / rare earth element molar ratio was 1.15. The pH during precipitation was adjusted to keep constant by adding ammonia water.

[0114] After precipitation, the reaction medium is kept at 60° C. for 15 minutes. The precipitate was then recovered by filtration, washed with water, then air dried and calcined at 850°C.

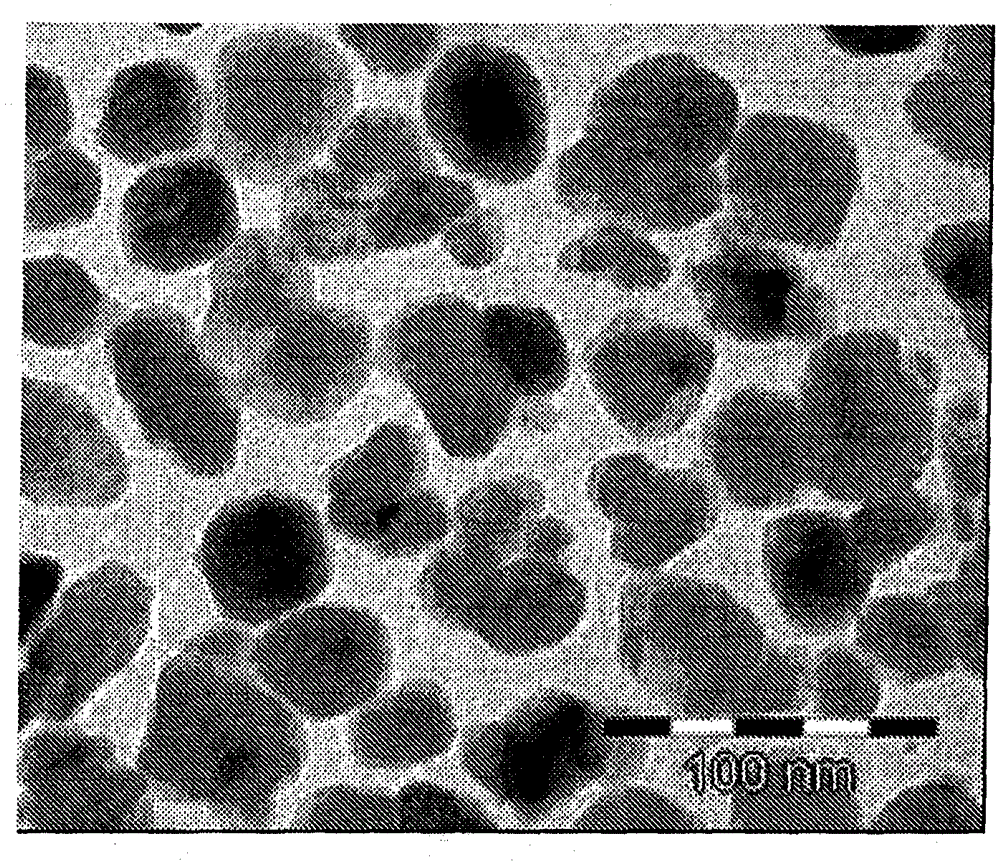

[0115] The powder thus obtained has a monazite-type LaCeTb phosphate structure. Use 0.4-0.6mm...

Embodiment 2

[0124] This example additionally relates to the preparation of lanthanum cerium terbium phosphate in powder form according to the invention.

[0125] The synthesis was the same as in Example 1, and then the slurry obtained from wet grinding was dried in an oven at 110° C. for 12 hours.

[0126] The dry product thus obtained in powder form is resuspended in water to give a suspension.

[0127] Laser particle size analysis of the suspension after sonication at a power of 450 W gave the following results:

[0128] d 16 (nm)

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com