Gas conditioning method for chicken wings

A processing method and technology for chicken wings, applied in the field of air conditioning processing, can solve the problems of lack of product variety, easy deboning of chicken wings, difficulty in keeping the color, aroma, taste and shape of chicken wings in good condition, achieving good protection effect and convenient eating. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Clean fresh chicken wings.

[0027] Marinated:

[0028] Mix the cleaned raw chicken wings with refined salt, rice wine and soy sauce, and let stand for 1.2 hours to obtain marinated chicken wings;

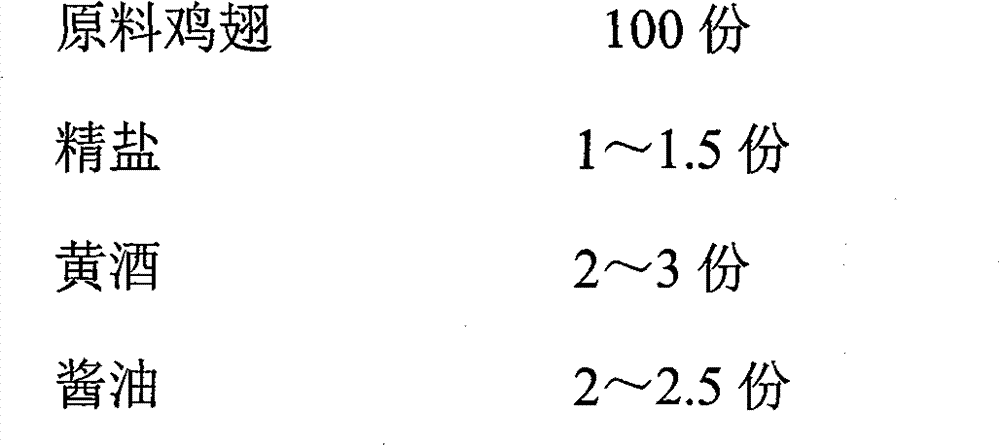

[0029] The parts by weight of components are as follows:

[0030] Raw chicken wings 100 servings

[0031] Refined salt 1.5 parts

[0032] 2 servings of rice wine

[0033] 2 parts of soy sauce.

[0034] Marinated:

[0035] Put the marinated chicken wings, seasoning and water in a pot, boil for 50 minutes, and keep warm for 18 minutes to get the marinated cooked chicken wings. After cooling, use PET-BOPA-AL-CPP composite film to bag and fill with nitrogen. seal;

[0036] The parts by weight of chicken wings after marinating, seasoning and water are as follows:

[0037] 100 servings of marinated chicken wings

[0038] Seasoning 3 servings

[0039] 6 parts water

[0040] Described condiment, condiment condiment comprises such as the component of weight part:

[0041]...

Embodiment 2

[0045] Clean fresh chicken wings.

[0046] Frying: Mix the cleaned raw chicken wings with refined salt, rice wine and soy sauce, let stand for 0.8 hours to obtain marinated chicken wings, put them in a pot and fry them for 3 minutes to obtain fried chicken wings;

[0047] The parts by weight of components are as follows:

[0048] Raw chicken wings 100 servings

[0049] Refined salt 1 part

[0050] 3 servings of rice wine

[0051] 2.5 parts of soy sauce.

[0052] Marinated:

[0053] Put the marinated chicken wings, seasoning and water in a pot, boil for 30 minutes, and keep warm for 22 minutes to get the marinated cooked chicken wings. After cooling, use PET-BOPA-AL-CPP composite film to bag and fill with nitrogen. seal;

[0054] The parts by weight of chicken wings after marinating, seasoning and water are as follows:

[0055] 100 servings of marinated chicken wings

[0056] Seasoning 4 servings

[0057] 7 parts water

[0058] Described condiment, condiment condiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com