Composite scale inhibitor as well as preparation method and application thereof

A composite antiscalant and equipment technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve problems such as material corrosion, reduce equipment life, and reduce production capacity, and achieve durable Good chlorine oxidation performance, reduced treatment costs, and reduced production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

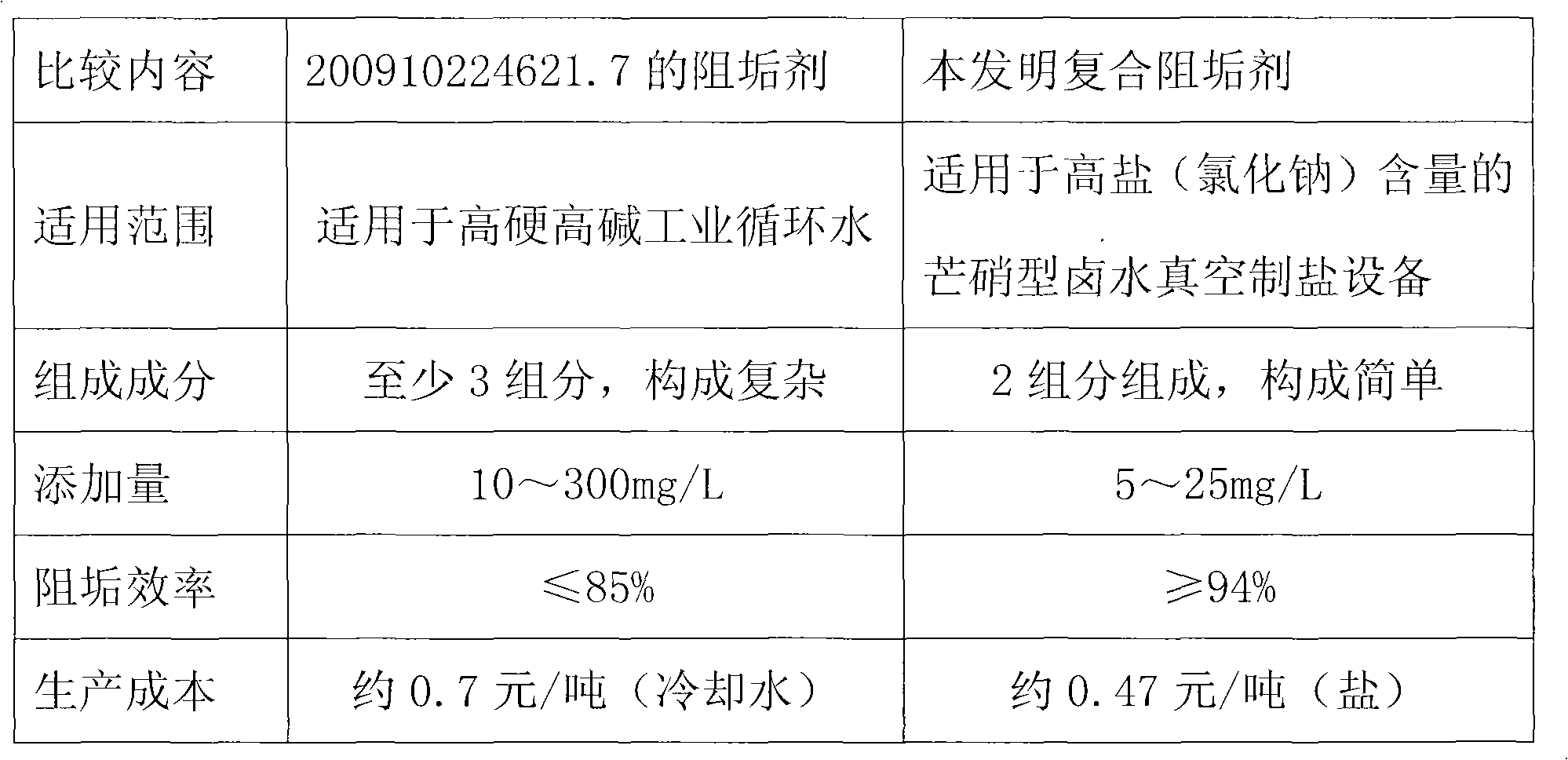

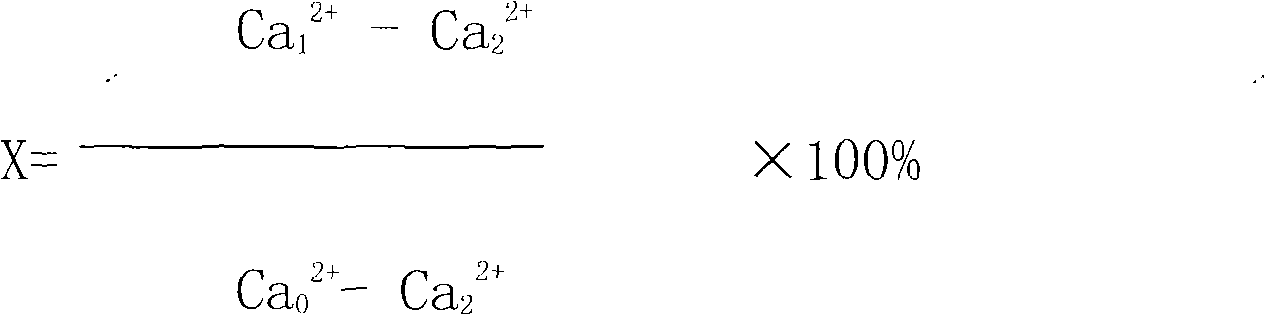

[0041]Prepare 24.2kg of scale inhibitors by adopting the ratio of binary composite scale inhibitor provided by the present invention, wherein polyaspartic acid 12.1kg, hydroxyethylidene diphosphonic acid (HEDP) 12.1kg, mix, stir evenly, adjust to pH2 .0. Then it was applied in the test solution required by "GB / T 16632-2008 Calcium Carbonate Deposition Method for Determination of Scale Inhibition Performance of Water Treatment Agents" according to the addition amount of 10mg / L, and the static scale inhibition test was carried out. The experimental results were: the scale inhibition rate reached 94.1%.

Embodiment 2

[0043] Prepare 12kg of scale inhibitors using the ratio of binary composite scale inhibitors provided by the present invention, including 2kg of polyaspartic acid and 10kg of hydroxyethylidene diphosphonic acid (HEDP), mix and stir evenly, and adjust to pH 1.0. Then, according to the addition amount of 12mg / L, it was applied to the test solution required by "GB / T 16632-2008 Calcium Carbonate Deposition Method for Determination of Scale Inhibition Performance of Water Treatment Agents", and the static scale inhibition test was carried out. The experimental results are: the scale inhibition rate reaches 94.2%.

Embodiment 3

[0045] Prepare 20kg of scale inhibitors by using the ratio of binary composite scale inhibitors provided by the present invention, including 5kg of polyaspartic acid and 15kg of hydroxyethylidene diphosphonic acid (HEDP), mix and stir evenly, and adjust to pH 3.0. Then, according to the addition amount of 15mg / L, it was applied to the test liquid required by "GB / T 16632-2008 Calcium Carbonate Deposition Method for Determination of Scale Inhibition Performance of Water Treatment Agents", and the static scale inhibition test was carried out. The experimental results were: the scale inhibition rate reached 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com