Tower-granulated low-nitrogen high-phosphorus urine sulfur radical compound fertilizer and preparation method thereof

A compound fertilizer and high-tower granulation technology, which is applied in the direction of fertilizer form, fertilizer mixture, fertilization device, etc., can solve the problems that are difficult to meet the needs of crop growth, so as to facilitate mechanized fertilization, improve the utilization rate of soil fertilizer, and resist pressure high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

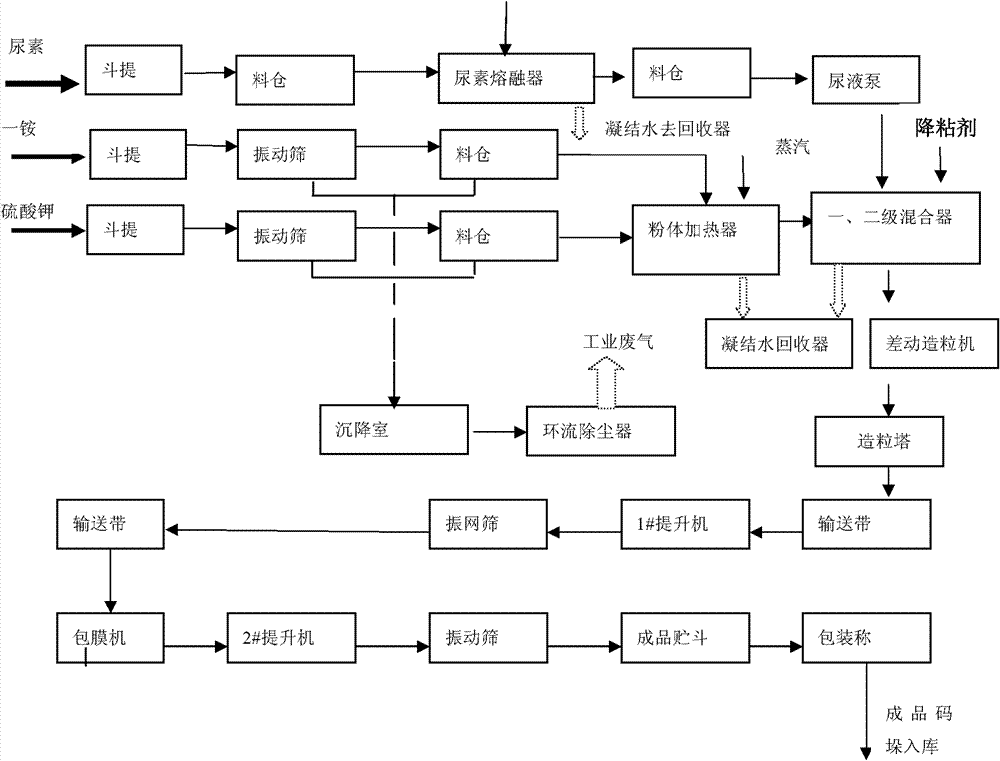

Image

Examples

Embodiment 1

[0047] Prepare the high-tower granulated low-nitrogen and high-phosphorus urea-sulfur-based compound fertilizer of the present invention according to the following steps

[0048] A. Pulping

[0049] a. Urea melting, metering and feeding

[0050] Pour granular urea into the urea belt conveyor, lift it to the urea silo through the bucket elevator, and enter the urea melter through the screw conveyor. After the urea melts, it flows into the urine buffer tank and is transported to the urea through the urine pump and mass flow meter. The first-level mixing tank on the top of the tower, the urea melt entering the first-level mixing tank is 35 parts by weight;

[0051] b. Measuring and feeding of other raw materials

[0052] The monoammonium phosphate and potassium sulfate are poured into the belt conveyor respectively, and are lifted to their respective silos by the bucket elevator. Electronic metering belt scales are installed at the bottom of the silo to measure 32.3 parts by we...

Embodiment 2~ Embodiment 7

[0056] According to the method and steps of Example 1, prepare the high-tower granulated low-nitrogen high-phosphorus urea-sulfur-based compound fertilizer of the present invention according to the raw material formula in Table 1

[0057] Table 1

[0058] raw material name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com