TiN coating silicon carbide fiber reinforced titanium-based composite material and preparation method thereof

A technology of titanium-based composite materials and silicon carbide fibers, which is applied in the field of coated carbon fiber-reinforced titanium-based composite materials and its preparation, can solve problems such as poor interface strength of TiN-coated silicon carbide fiber-reinforced composite materials, and reduce the degree of interface reaction. Achieve good material performance, reduce the degree of interfacial reaction, and good interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

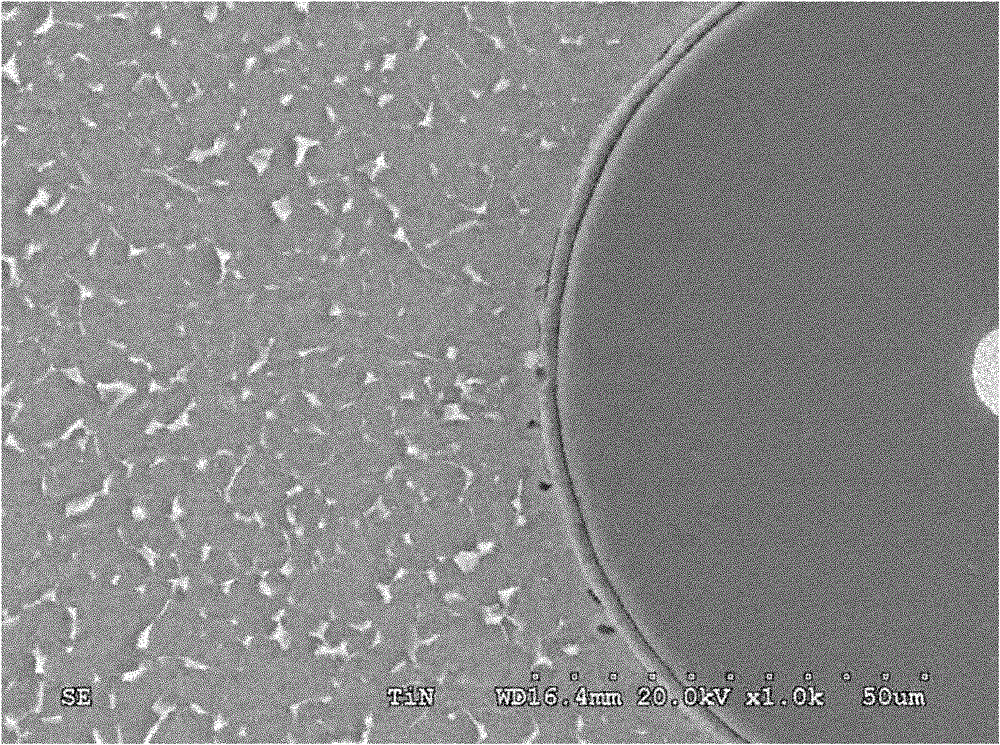

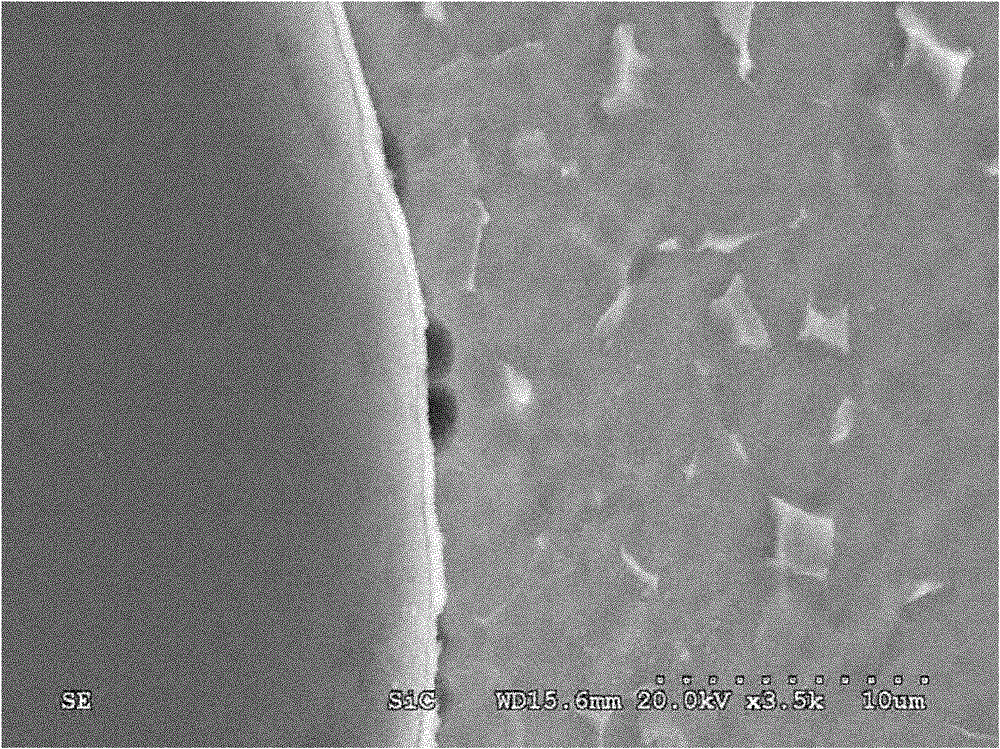

[0012] Specific Embodiment 1: The TiN-coated silicon carbide fiber-reinforced titanium-based composite material of this embodiment is made by vacuum hot pressing of alternately stacked foils and TiN-coated silicon carbide fiber cloth. The TiN-coated silicon carbide The thickness of the TiN coating on the fiber cloth is 1-3 μm, and the TiN coating is applied to the surface of the silicon carbide fiber by magnetron sputtering technology, and the foil material is titanium foil, titanium alloy foil or titanium aluminum alloy foil.

[0013] The interface reaction degree of the TiN-coated silicon carbide fiber-reinforced titanium-based composite material in this embodiment is significantly reduced, has good interface properties, and has greatly improved tensile strength.

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment differs from Embodiment 1 in that the thickness of the TiN coating of the TiN-coated silicon carbide fiber cloth is 2 μm. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the thickness of the foil is 50 μm to 200 μm. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com