Two-stage expansion piston air motor device

A pneumatic engine and two-stage expansion technology, applied in the field of power devices, can solve problems affecting the working efficiency of the system, achieve stable power output, improve energy use efficiency, and high energy transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

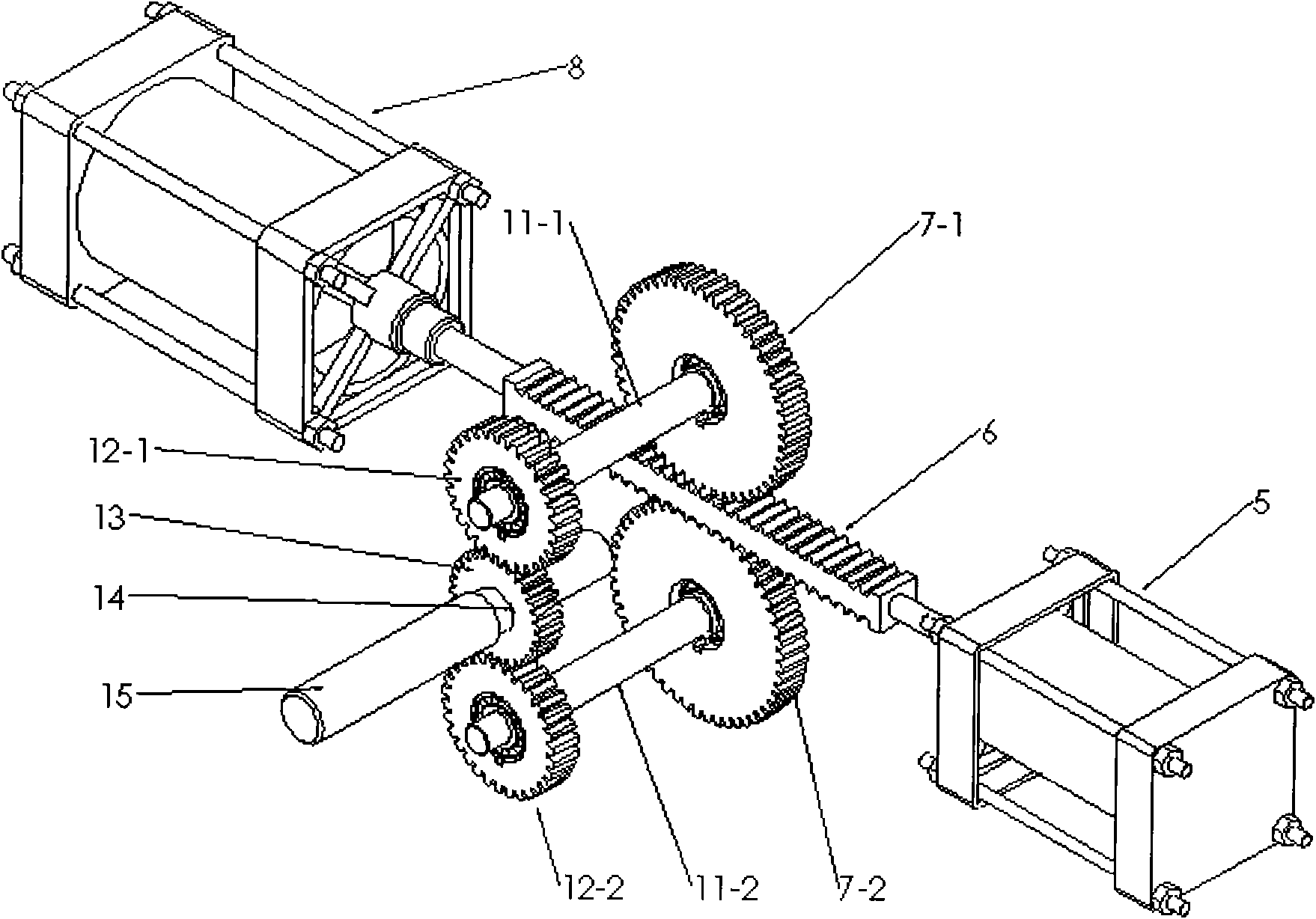

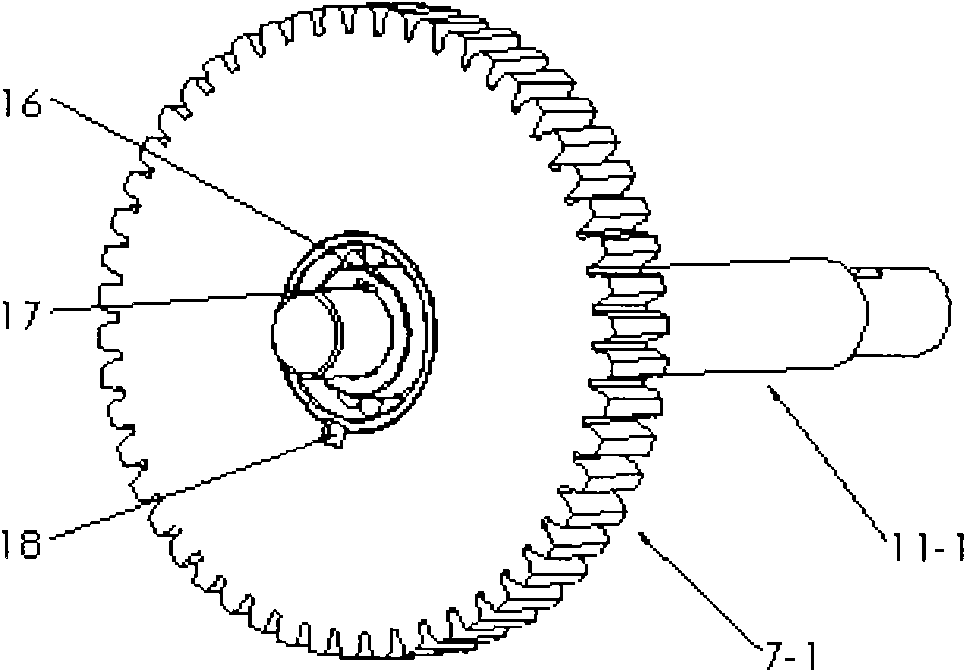

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

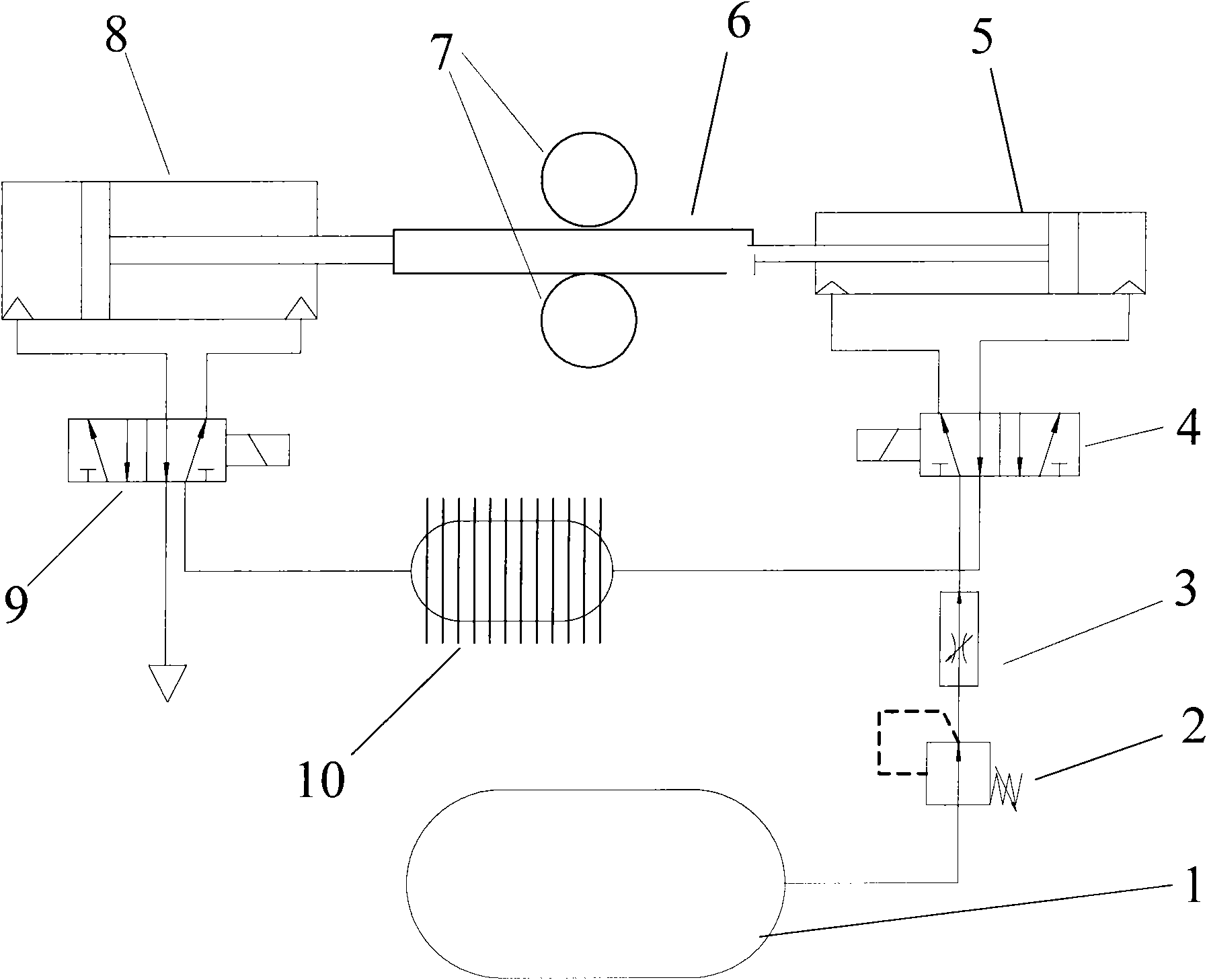

[0012] Such as figure 1 Shown is a schematic diagram of the air pressure control loop system of the present invention. Wherein comprise a gas tank 1, there is the compressed gas of 30Mpa in the gas tank, pressure reducing valve 2 is connected with 1 through flexible pipe, and its function is to reduce the compressed gas of 30Mpa to 1Mpa. After the throttle valve 3 is connected to the pressure reducing valve 2, the function of the throttle valve 3 is to adjust the flow rate of the gas. A valve port at the lower end of the first electromagnetic reversing valve 4 is connected to the throttle valve 3, and the other valve port is connected to the transition gas tank and the heat exchange system 10, and the effect of the 10 is to make the passing gas absorb the heat of the external environment. The two valve ports at the upper end of the 4 are connected to the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com