Heat exchange tube for evaporator and evaporator formed by same

A technology for evaporators and heat exchange tubes, which is applied in the direction of evaporators/condensers, refrigeration components, tubular elements, etc., which can solve the problems of inability to solve the charging volume of refrigeration systems, complex system structures, and limited applications, and achieve omission of throttling The effect of step-down process, solving application limitations, and reducing filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

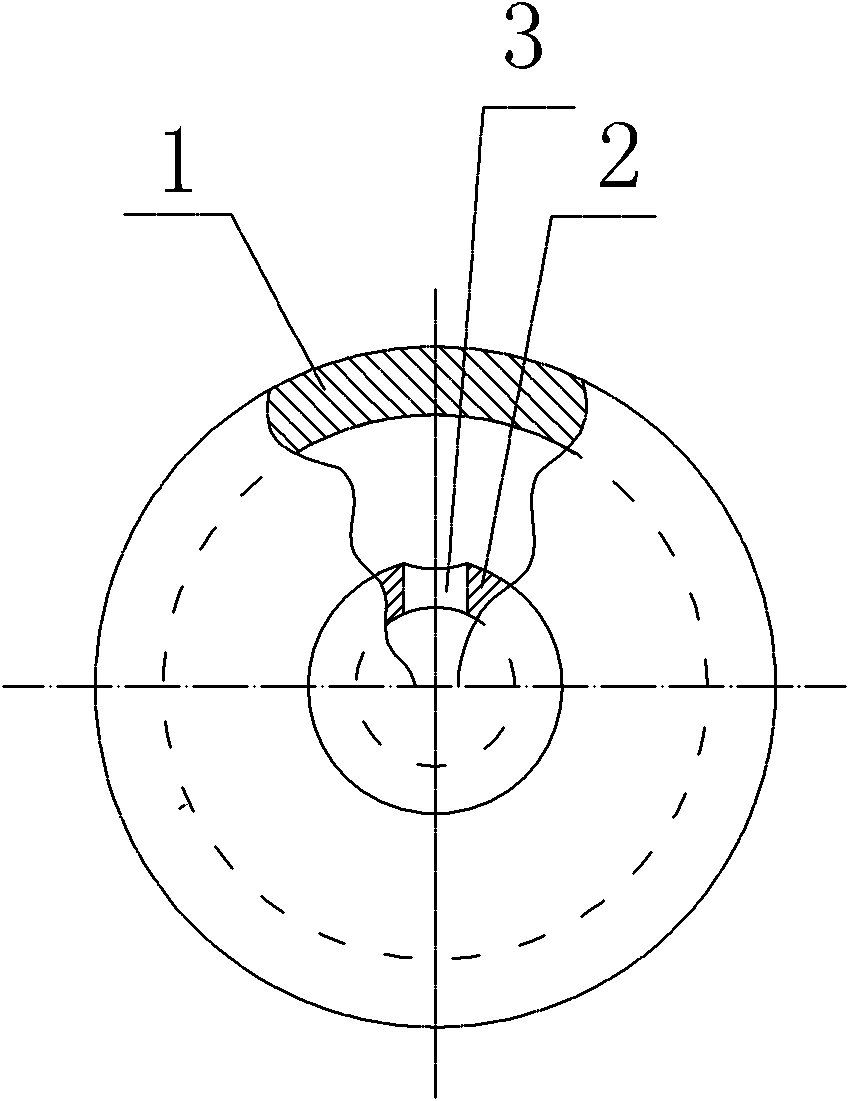

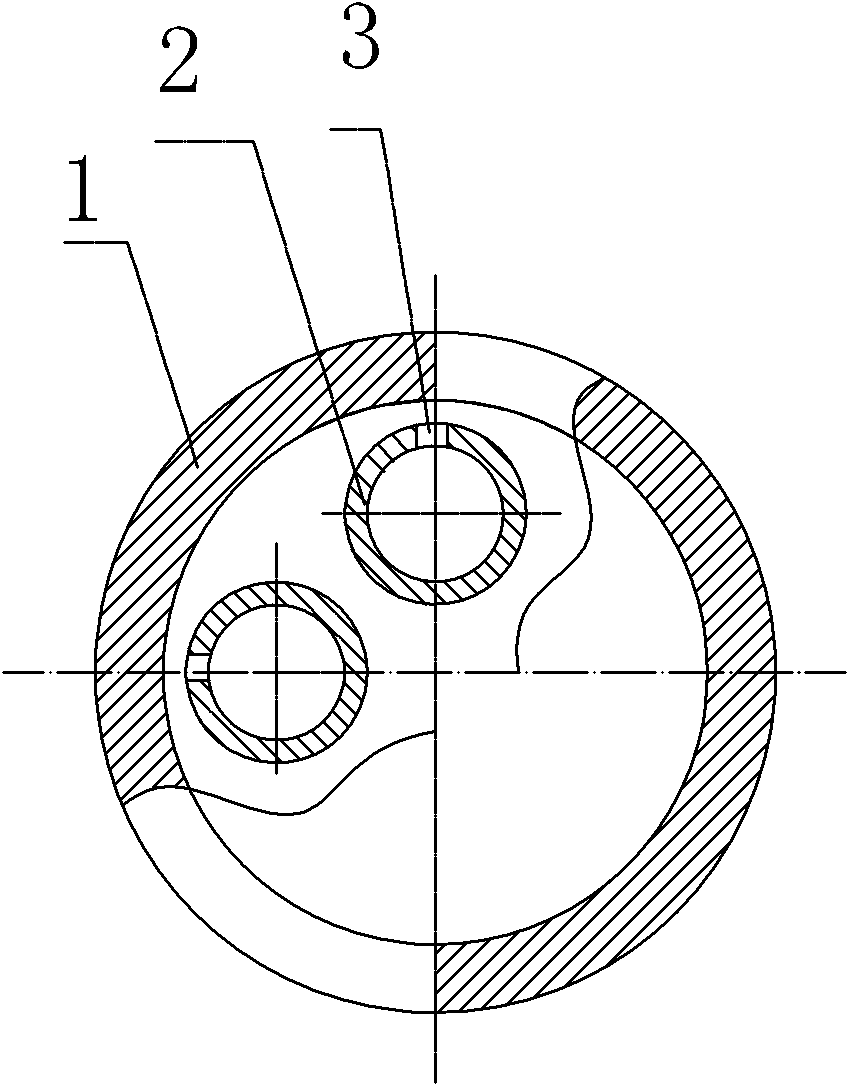

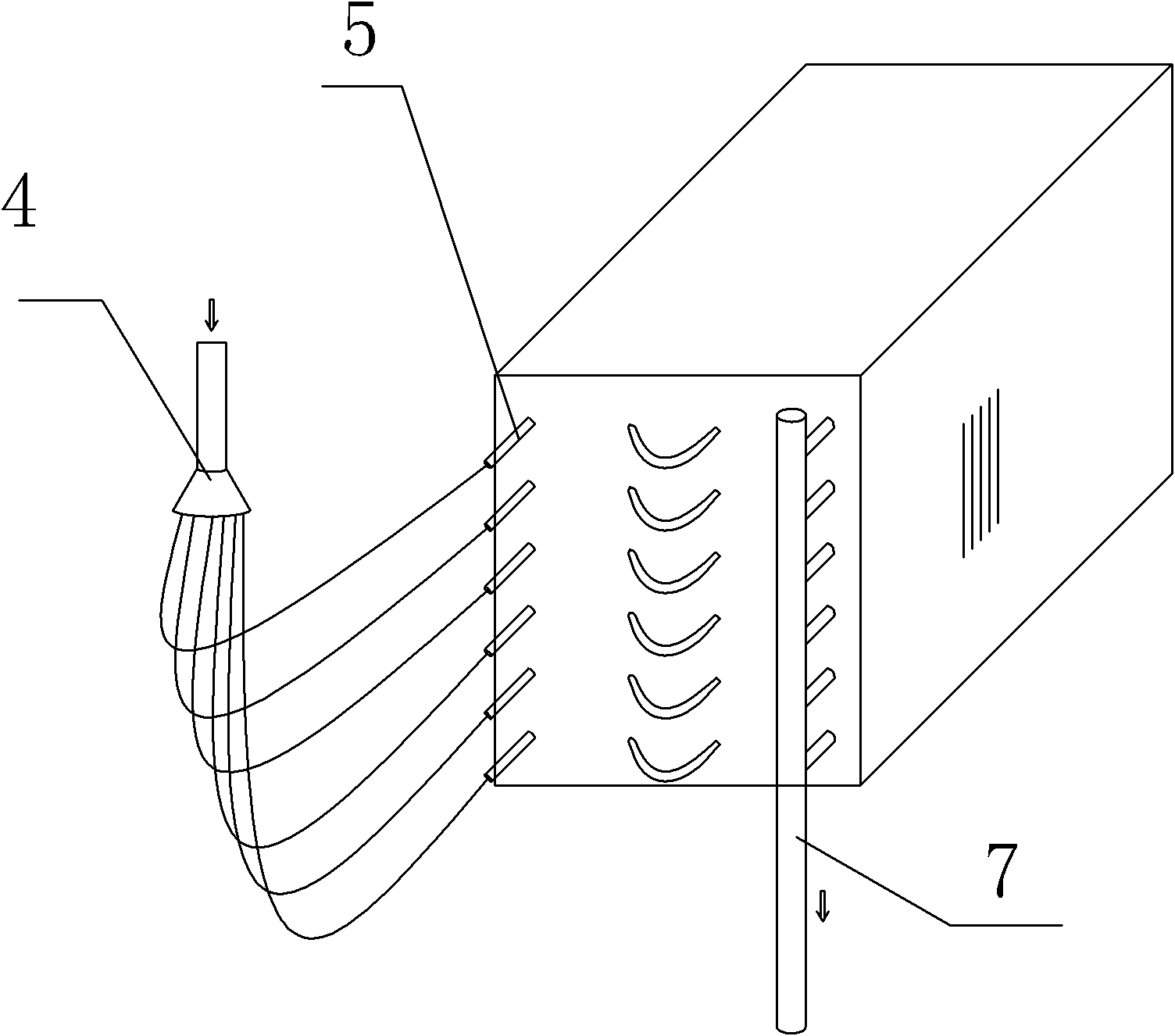

[0028] The heat exchange tube used in the evaporator of the present invention comprises an outer tube 1 and at least one inner tube 2, figure 1 It is a cross-sectional view of a single inner tube in the outer tube of the heat exchange tube used in the evaporator of the present invention, figure 2 It is a cross-sectional view of multiple inner tubes inside the outer tube of the heat exchange tube used in the evaporator of the present invention. At least one inner tube 2 is installed inside the outer tube 1 , and a plurality of jet holes 3 are arranged on the inner tube 2 . The outer tube and the inner tube can be combined in various ways, and the spray holes 3 can be arranged in various ways. The outer tube is a smooth tube or a corrugated tube. The diameter of the inner pipe is preferably 3 to 5 mm, and the diameter of the jet orifice is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com