Inner diameter multiparameter measuring device for large length-to-diameter ratio pipe and measuring method thereof

A technology with large aspect ratio and measuring device, which is applied in measuring device, electromagnetic measuring device, electric/magnetic diameter measurement, etc. Reasonable design of the measurement structure, easy to print or save, and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

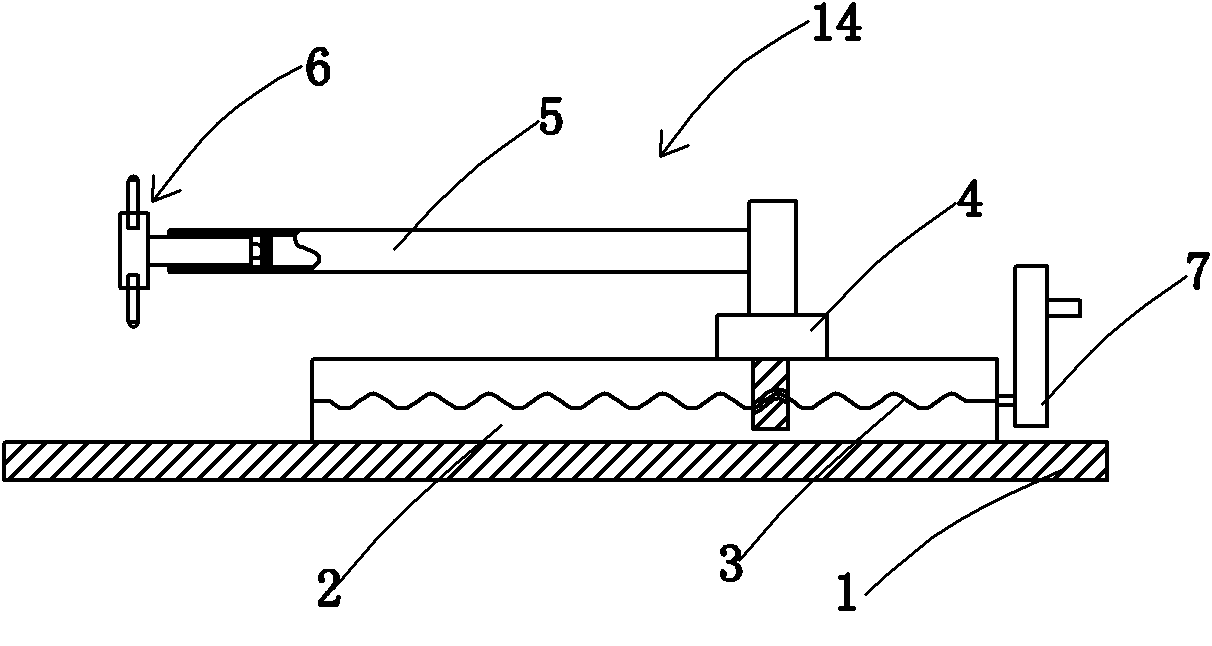

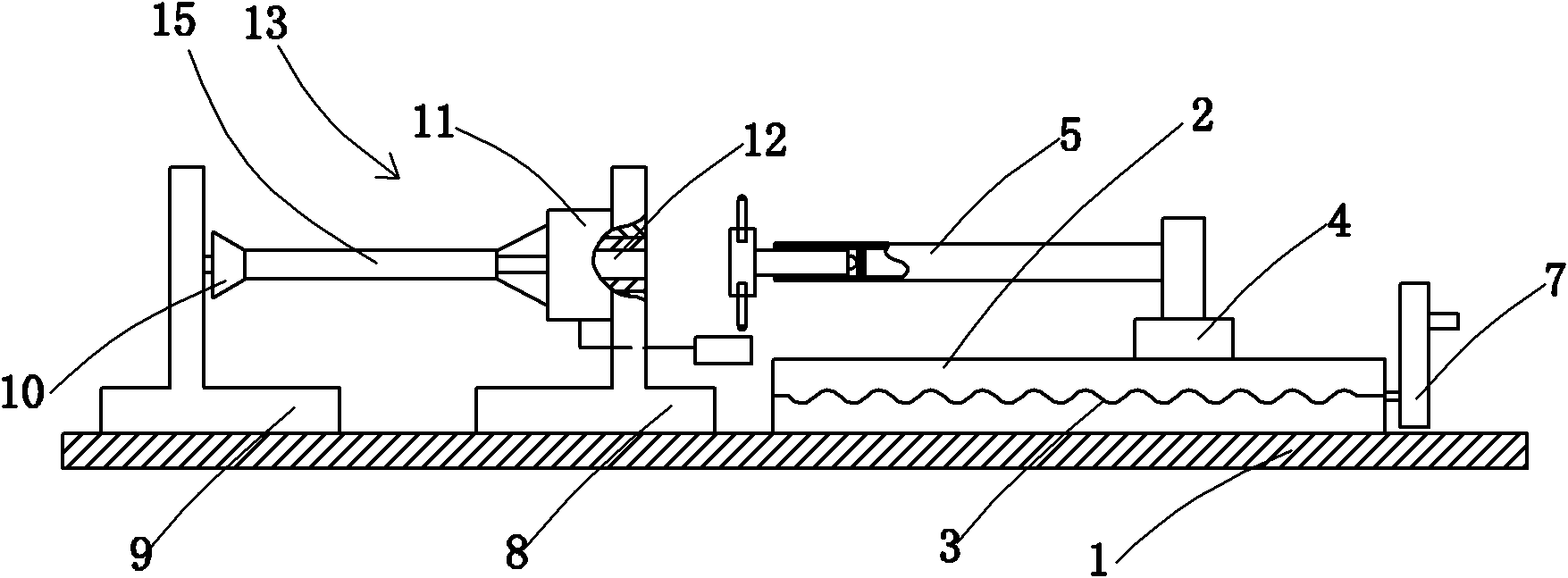

[0023] Embodiment: the measuring device of the present embodiment is as Figure 4 As shown, it is suitable for measuring multiple parameters such as inner diameter, roundness, and straightness of pipe fittings with a large aspect ratio. with measuring mechanism 14 .

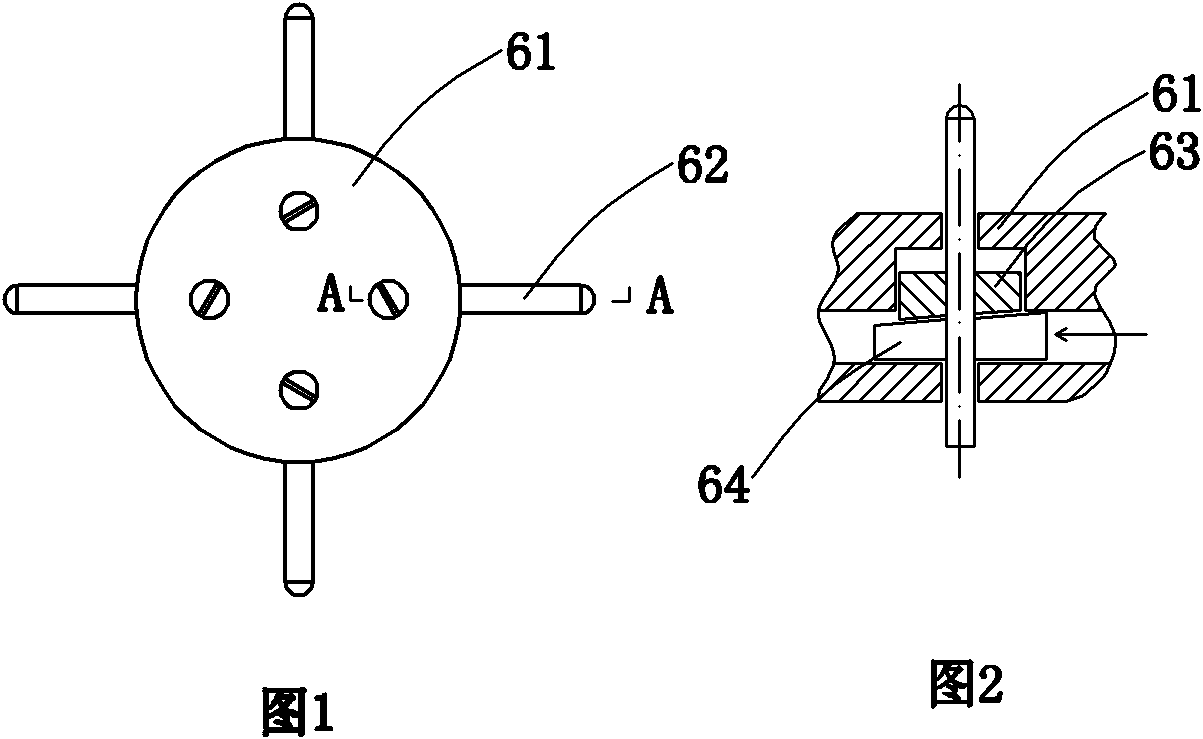

[0024] see image 3 , the measuring mechanism 14 includes: a guide rail 2 arranged at one end of the measuring platform, a lead screw 3 is horizontally provided inside the guide rail, the lead screw 3 is driven to rotate horizontally by a handwheel 7, and a sliding block 4 matching it is provided on the guide rail 2, The slide block is driven by the lead screw 3 and can reciprocate horizontally along the guide rail. The slide block is detachably connected with a clamping rod 5 extending to the clamping mechanism 13, and four ends of the clamping rod 5 are provided. A sensor 6, the axis of the sensor is perpendicular to the axis of the clamping rod.

[0025] The pipe 15 is horizontally fixed and clamped by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com