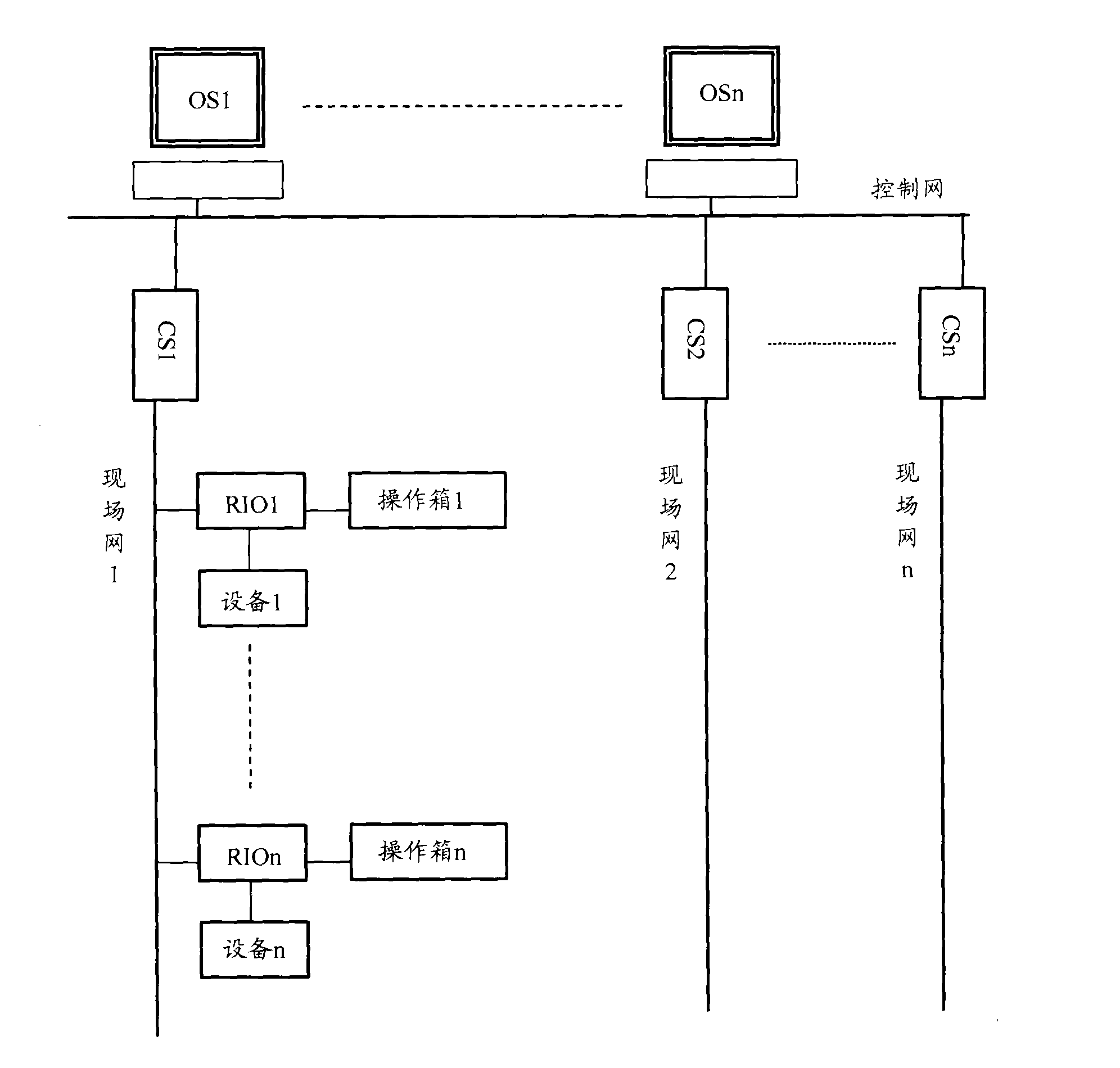

Control system of sintering plant

A control system and control station technology, applied in the direction of comprehensive factory control, comprehensive factory control, transmission system, etc., can solve the problems of long failure time, high operation intensity, cumbersome operation, etc., and achieve the effect of shortening the failure time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

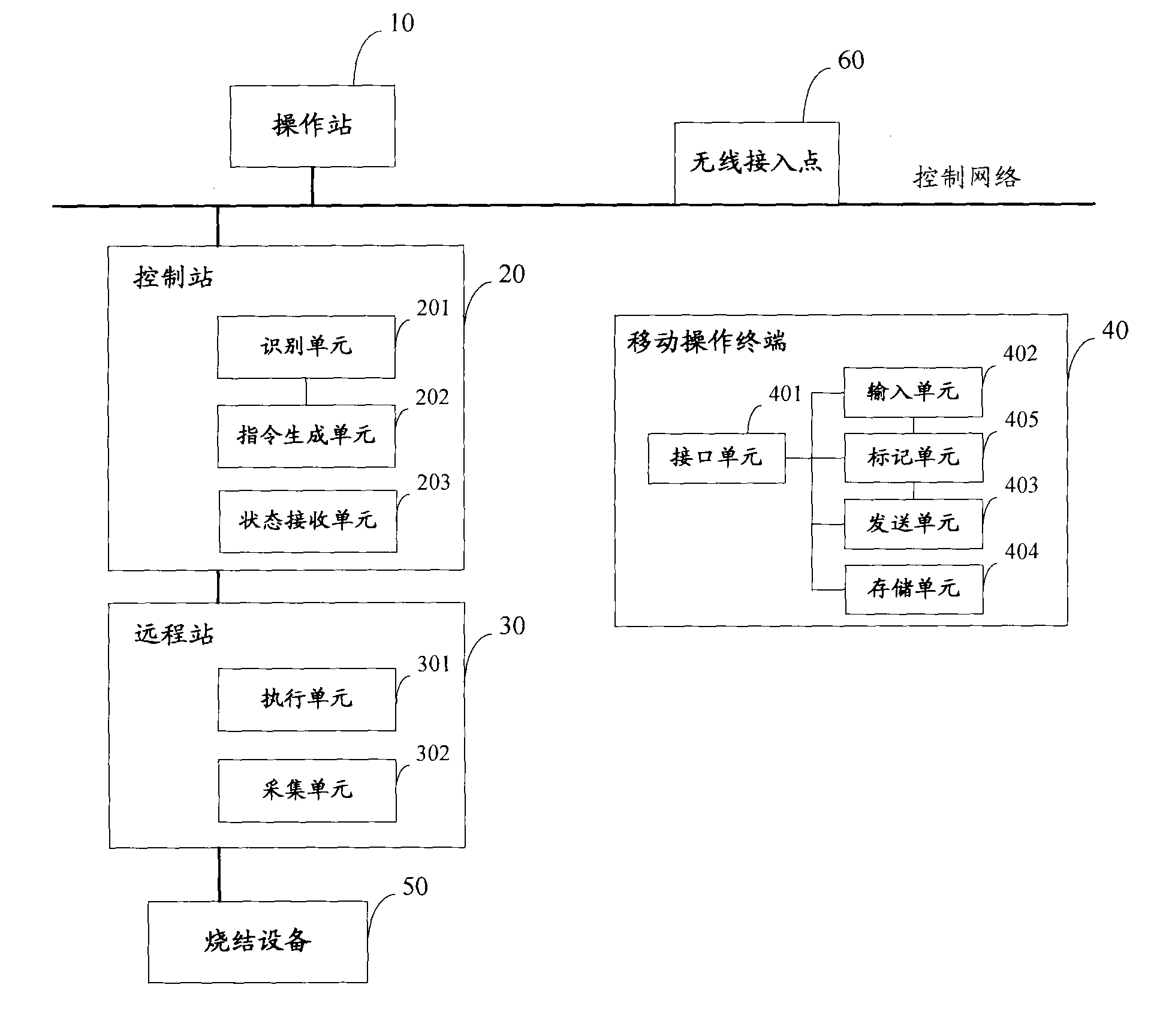

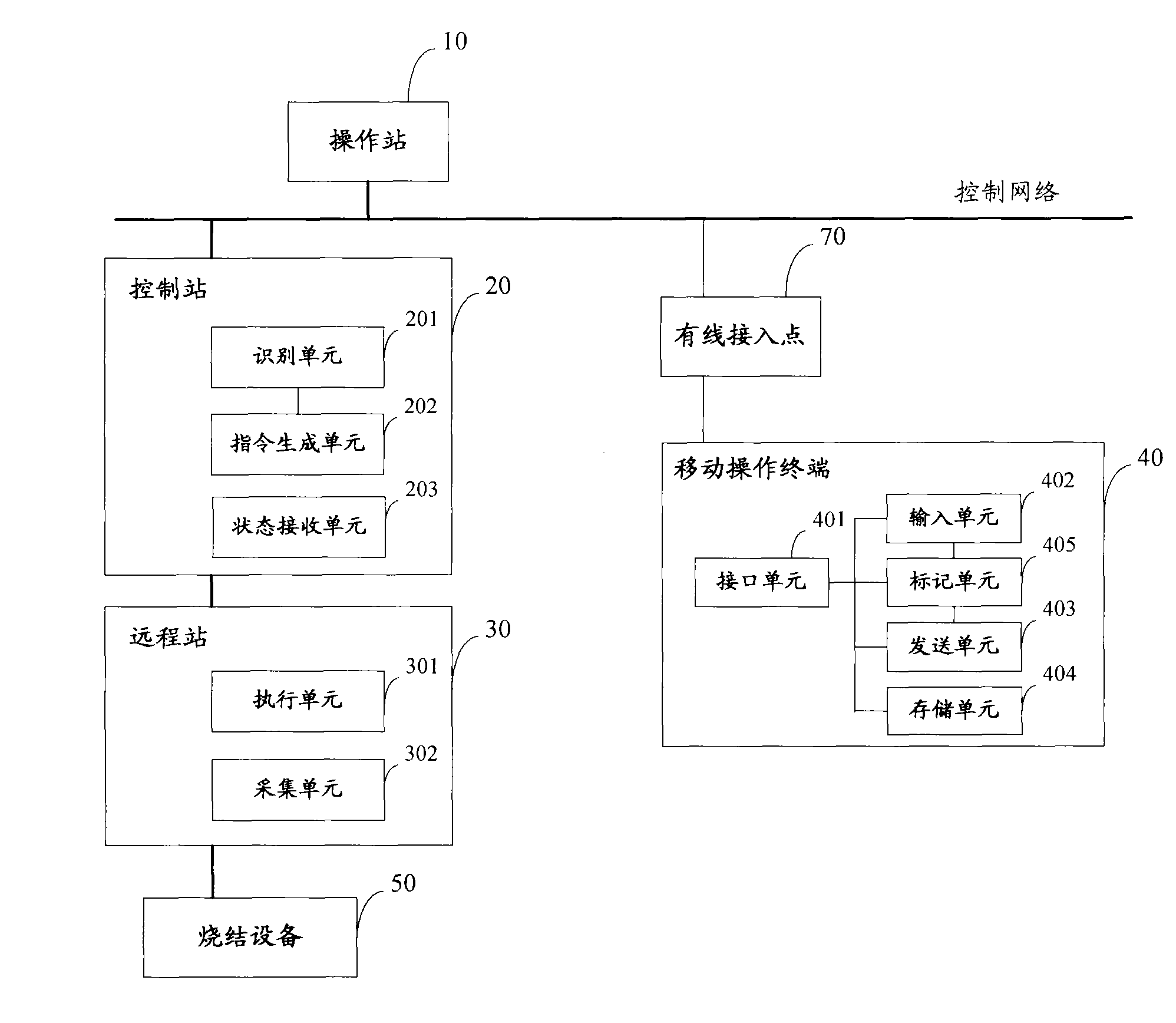

[0043] The purpose of the present invention is to provide a control system of a sintering plant, which can simplify site layout, reduce operation intensity, reduce failure time and improve production efficiency.

[0044] In order to make those skilled in the art understand the sintering plant control system of the present invention more clearly, detailed description will be given below in conjunction with specific drawings.

[0045] The sintering plant control system of the present invention adopts a distributed structure, including an operation station, a control station, a remote station, a mobile operation terminal, and sintering equipment.

[0046] Both the operation station and the control station are connected to the control network.

[0047] The operation station provides a human-machine interface HMI, which is mainly responsible for centralized monitoring of on-site working conditions, data recording, parameter setting, timing storage, report printing and alarm prompt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com