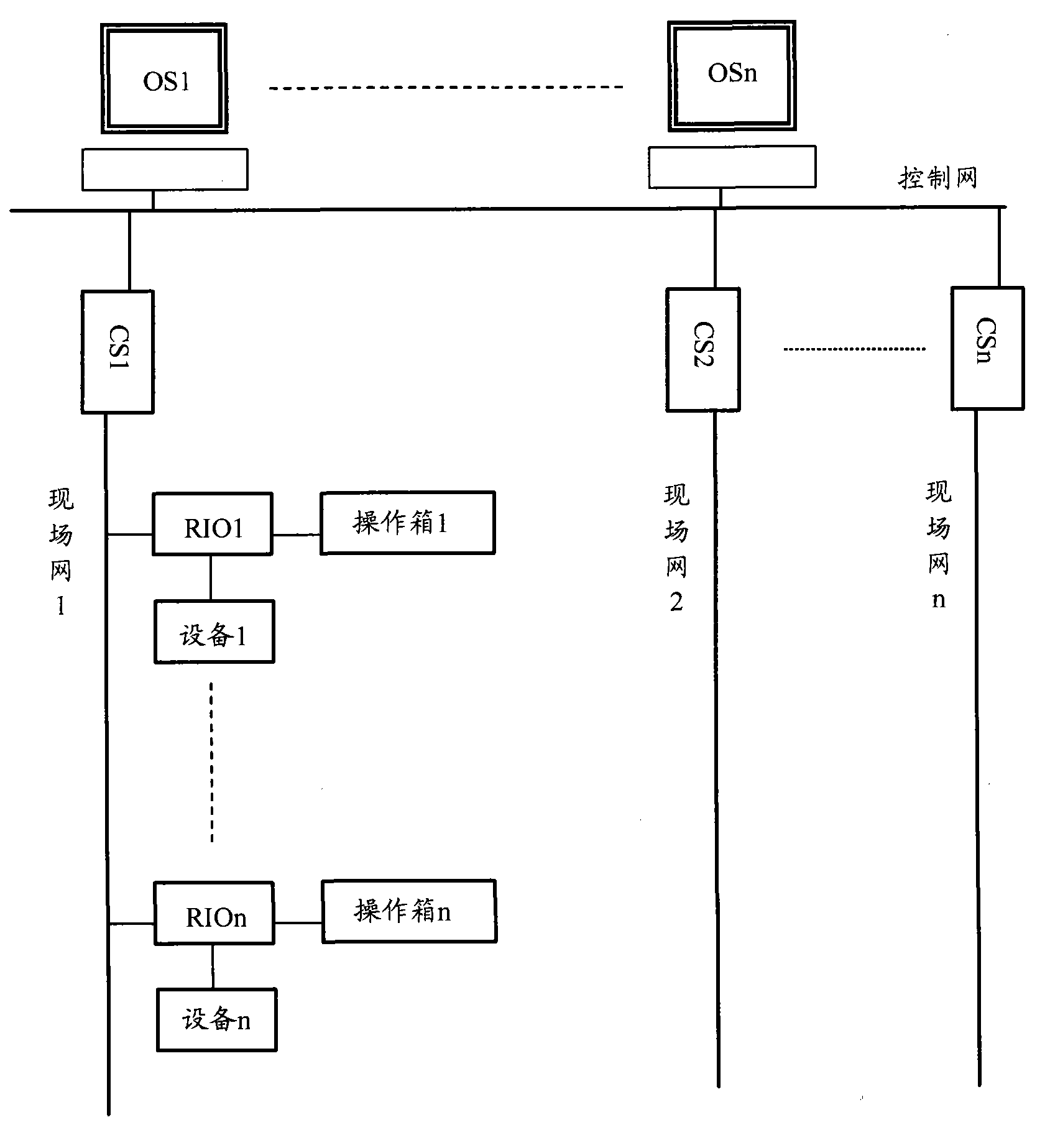

Control system of sinter plant

A control system and controller technology, applied in the field of sintering, can solve the problems of high operation intensity, long failure time, complicated operation, etc., and achieve the effects of improving production efficiency, shortening failure time, and saving pipeline resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The purpose of the present invention is to provide a control system of a sintering plant, which can simplify site layout, reduce operation intensity, reduce failure time and improve production efficiency.

[0061] In order to make those skilled in the art understand the sintering plant control system of the present invention more clearly, detailed description will be given below in conjunction with specific drawings.

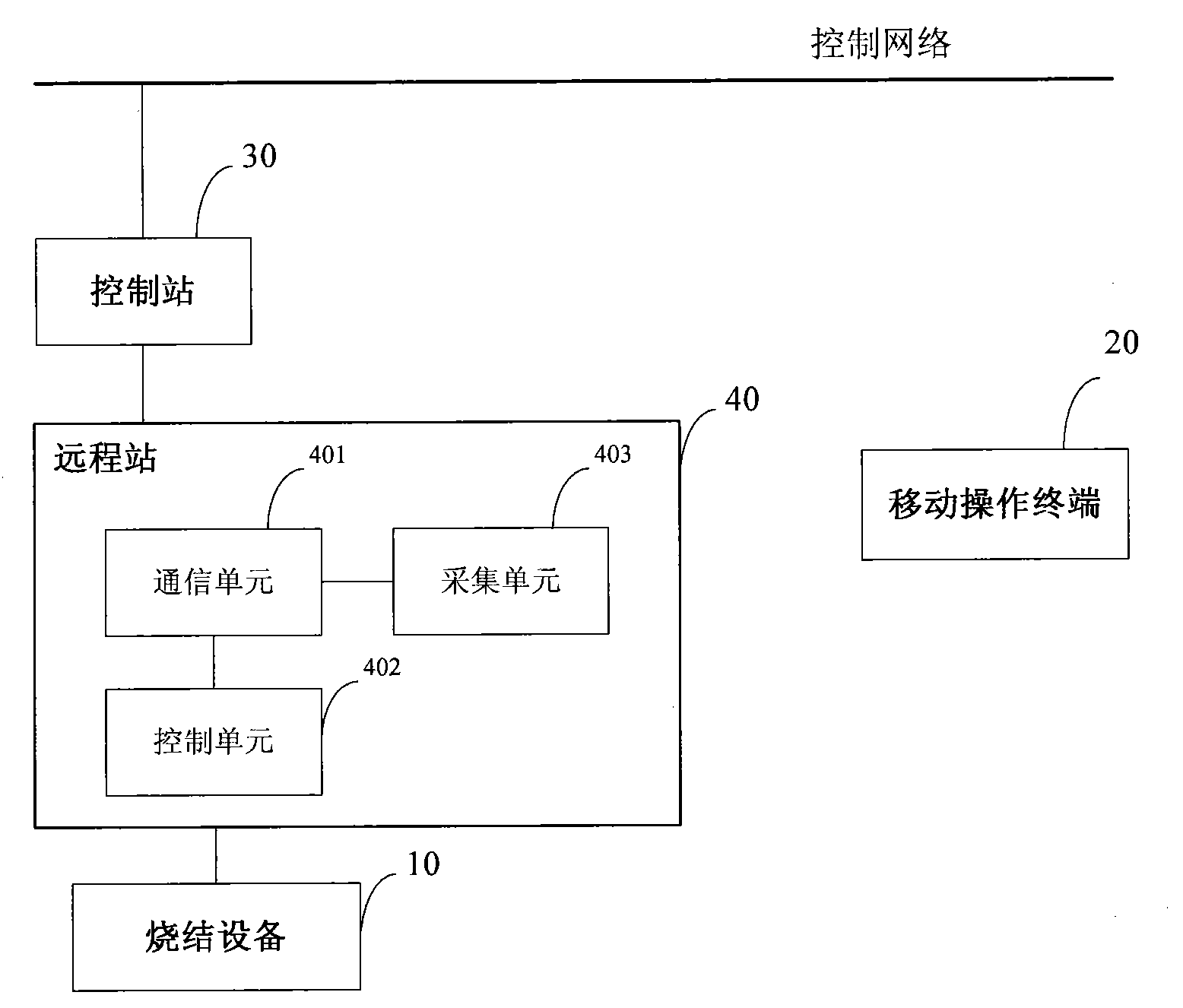

[0062] see figure 2 , is a structural diagram of the sintering plant control system according to the first embodiment of the present invention.

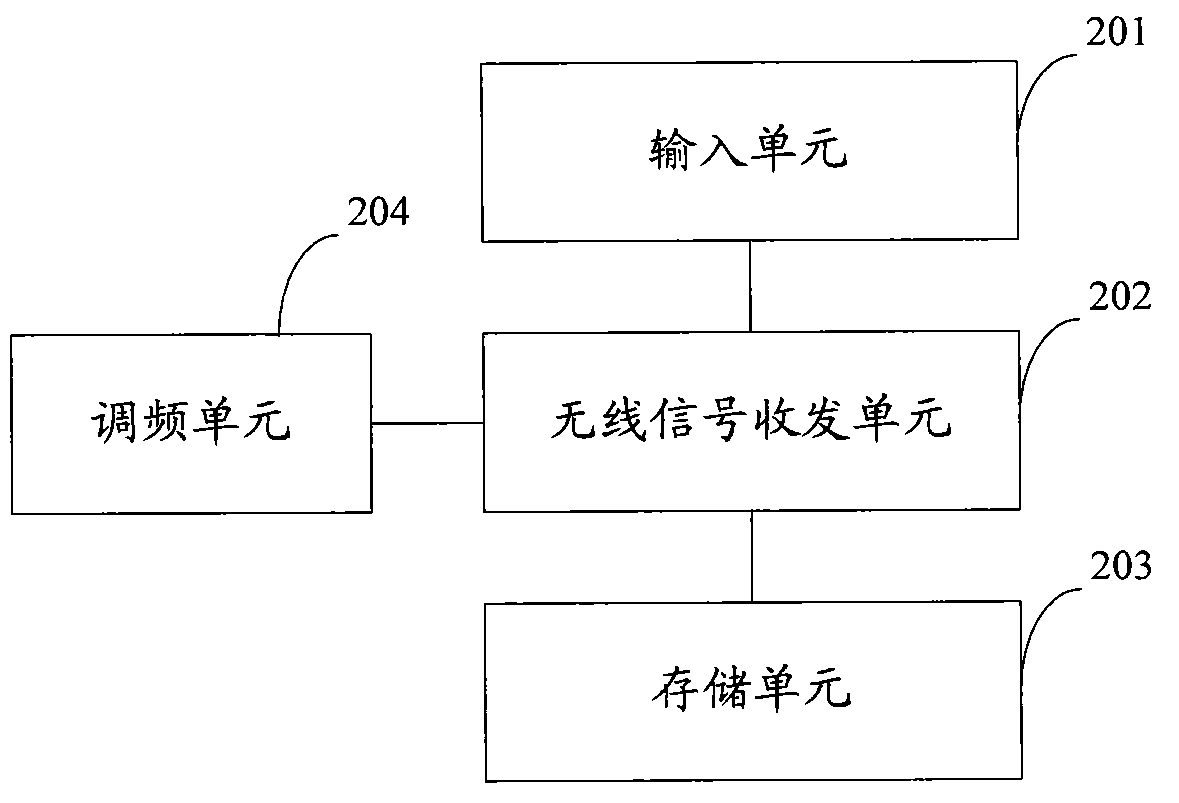

[0063] The system includes a sintering equipment 10 and a control network, a mobile operating terminal 20 , a control station 30 , and a remote station 40 . in,

[0064] The control station 30 is connected to the control network and is used to receive sintering equipment status information and generate sintering equipment operation instructions;

[0065] The remote station 40 is used to connect the sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com