Lead-acid accumulator grid suitable for high-efficiency discharge

A lead-acid battery, high-efficiency technology, applied in the direction of electrode carrier/collector, etc., can solve the problems of broken ribs, shortened battery life, easy corrosion of pores, etc., achieve uniform ribs, reduce production costs, Good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

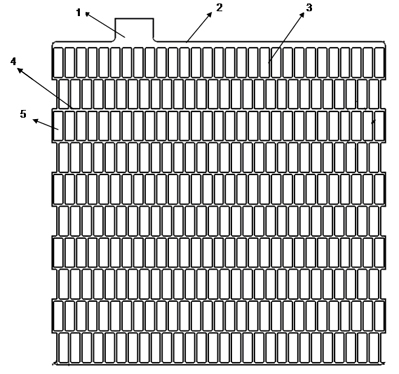

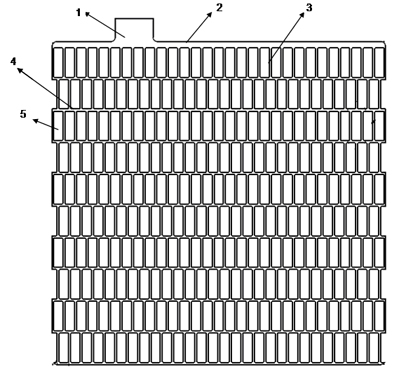

[0010] Such as figure 1 As shown, the grid includes a tab 1, a frame 2 and a grid 5. The vertical ribs 3 and the horizontal ribs 4 are cross-connected to form a grid 5. The grid 5 is arranged inside the frame 2, and the tab 1 is welded outside the frame 2. , forming a grid as a whole.

[0011] Wherein, the tabs 1, the horizontal ribs 4, the vertical ribs 3 and the frame 2 have the same thickness, and the grid length direction is consistent with the grid height direction.

[0012] When assembling, apply lead paste on the grid to make a pole plate, pack the positive and negative plates and separators according to the ratio, and then make an electrode group by casting welding. , charging and other processes, a high-efficiency discharge lead-acid battery is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com