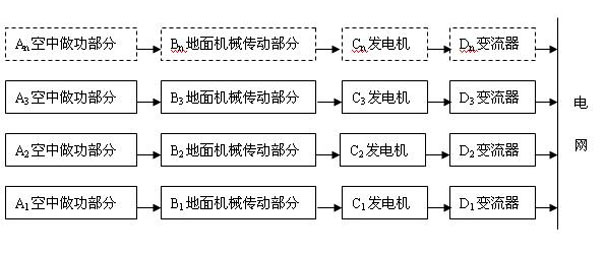

Power confluence method of multiple high altitude wind generating sets for intermittent power generation

A technology of wind power generating set and power, which is applied in the direction of wind power motor combination, wind power engine, engine, etc. It can solve the problems of large generator capacity, tether winding, and infeasibility, so as to reduce the demand of control design, flexible installation position, Good output stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

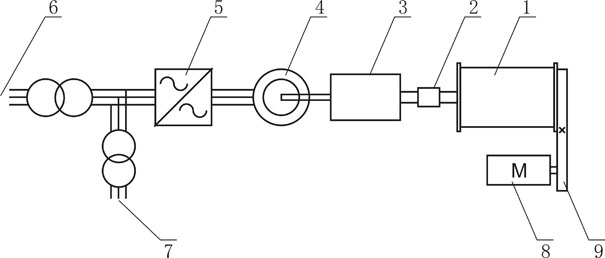

[0030] see figure 2 : The wind power generating set includes air parachute and ground part, the ground part is composed of reel 1, one-way clutch 2, gear box 3, generator 4, full power converter 5, auxiliary motor 8, and the auxiliary motor passes through the transmission mechanism 9 connect the reel 1. The aerial work parachute floats in the air, and its tether is wound on the reel 1. In order to prevent the reel 1 from driving the generator 4 to reverse, a one-way clutch 2 is installed between the reel 1 and the speed-increasing gear box 3. The movement between the generators 4 is disengaged, and the generators 4 do not reverse. The output side of the full power converter 5 is provided with a self-use electrical port 7 for supplying power to the auxiliary motor 8 .

[0031] Its working principle is that when the aerial power-working parachute rises against the wind, the tether traction reel 1 rotates, speeds up through the gear box 3, and drives the generator 4 to genera...

example 2

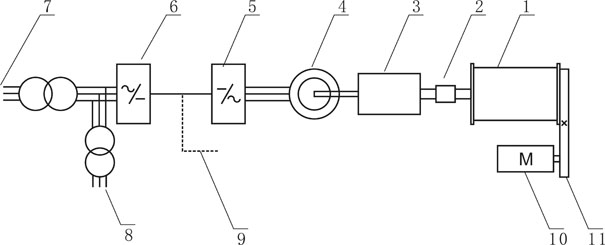

[0033] see image 3 : Its basic structure and diagram 2 Roughly the same, only the choice of confluence point of power is different. It consists of a drum 1, a one-way clutch 2, a gearbox 3, a generator 4, a rectifier 5, an inverter 6, an auxiliary motor 10, and a transmission mechanism 11. There is a grid-connected output terminal 7 and an auxiliary motor power supply terminal 8 . The difference is that the confluence node 9 is the DC bus bar of the converter. figure 2 and image 3 The difference between the proposed electrical confluence methods lies in the selection of the power confluence points of multiple high-altitude wind energy generator sets. figure 2 The power confluence point is selected at the AC end of the converter, and image 3 Choose to merge at the DC busbar, and different choices of junction points will bring different requirements for components, especially inverters. For the confluence mode of the AC side, the capacity of the inverter is equal to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com