Energy-saving compound air-conditioning device for food freezing and thawing device

A composite, food technology, used in the field of food cooling, storage and thawing, can solve the problems of contaminated frozen products and soluble loss, microbial contamination, uneven heating, etc., and achieve the effect of simplifying equipment, reducing area and reducing frost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

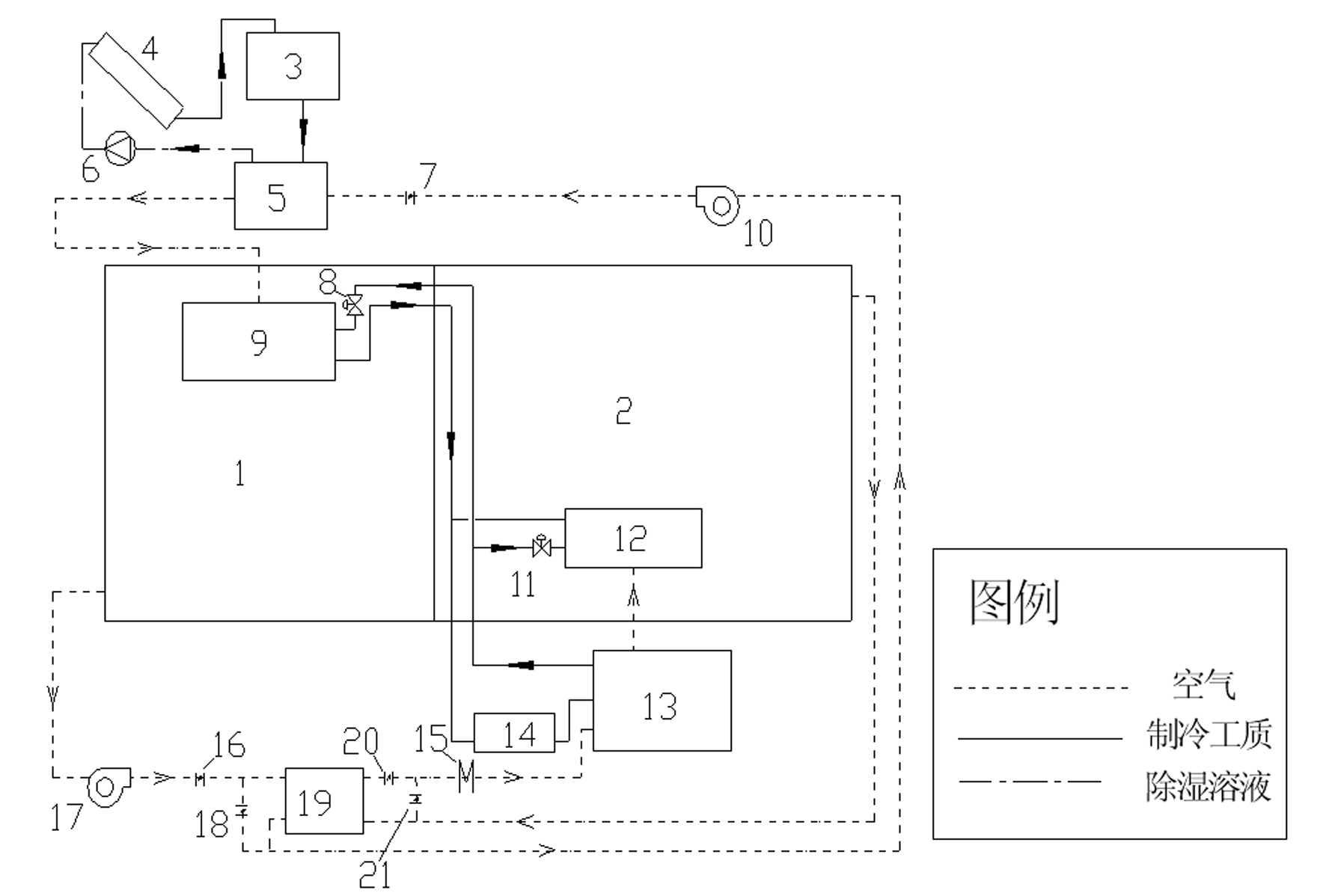

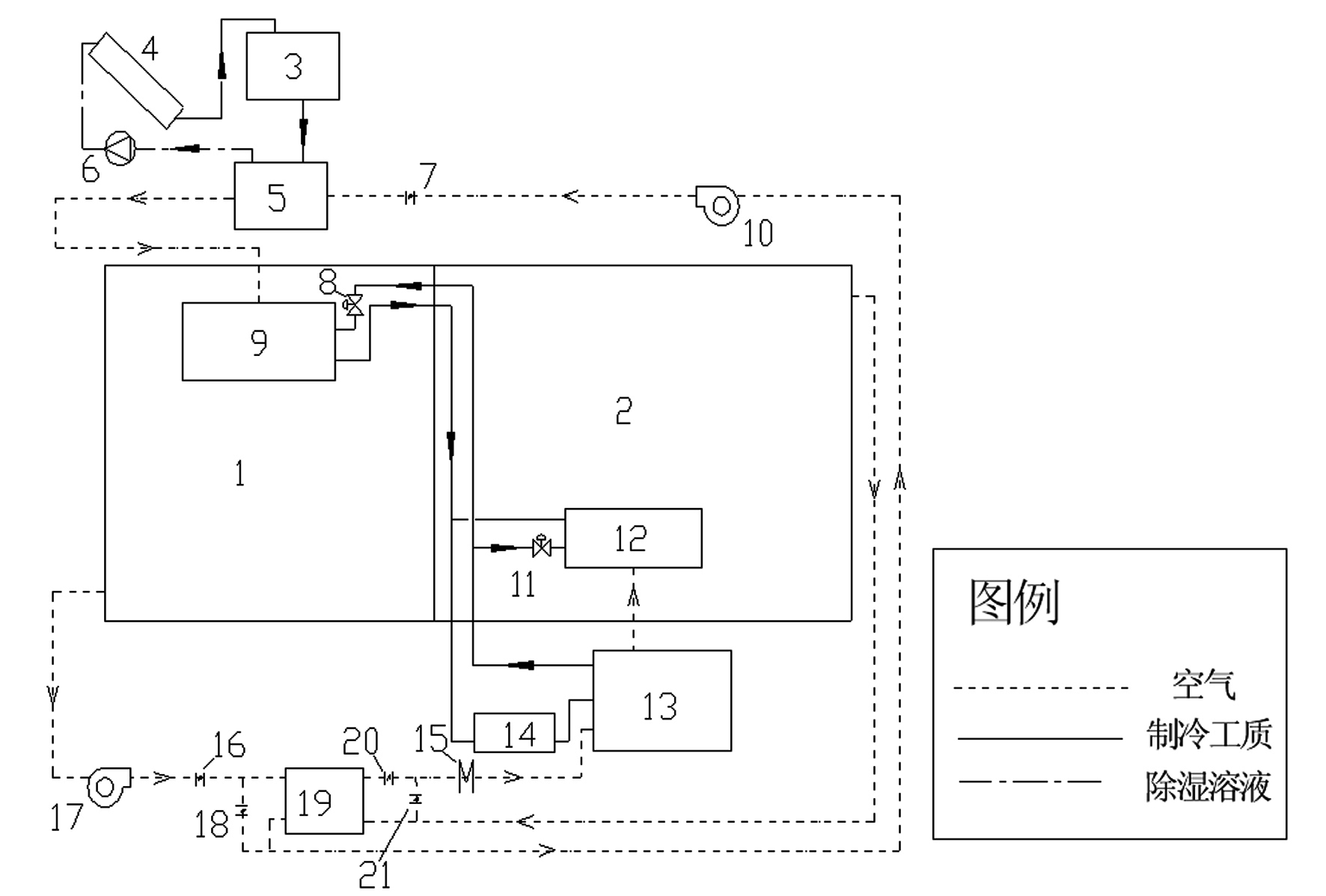

[0017] Attached below figure 1 Further details on the examples of the invention:

[0018] The energy-saving composite air-conditioning system of the food freezing and thawing device is composed of three sub-cycles, that is, a solution dehumidification cycle, a refrigerant cycle and an air cycle. The freezing and thawing process of food is that the air entering the freezer first passes through the solution dehumidifier 5 for dehumidification and lowering the enthalpy, and then it is sent into the freezing chamber to be further cooled by the first evaporator 9, and then the food in the freezing chamber 1 is frozen. Then the air that has been used is returned under the action of the second blower fan 17, and the return air of one of the two routes passes through the gas heat exchanger 19 and the return air from the thawing chamber 2. After heat exchange and heating, it is sent into the shower condensation After heating and humidifying by the device 13, it is sent to the thawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com