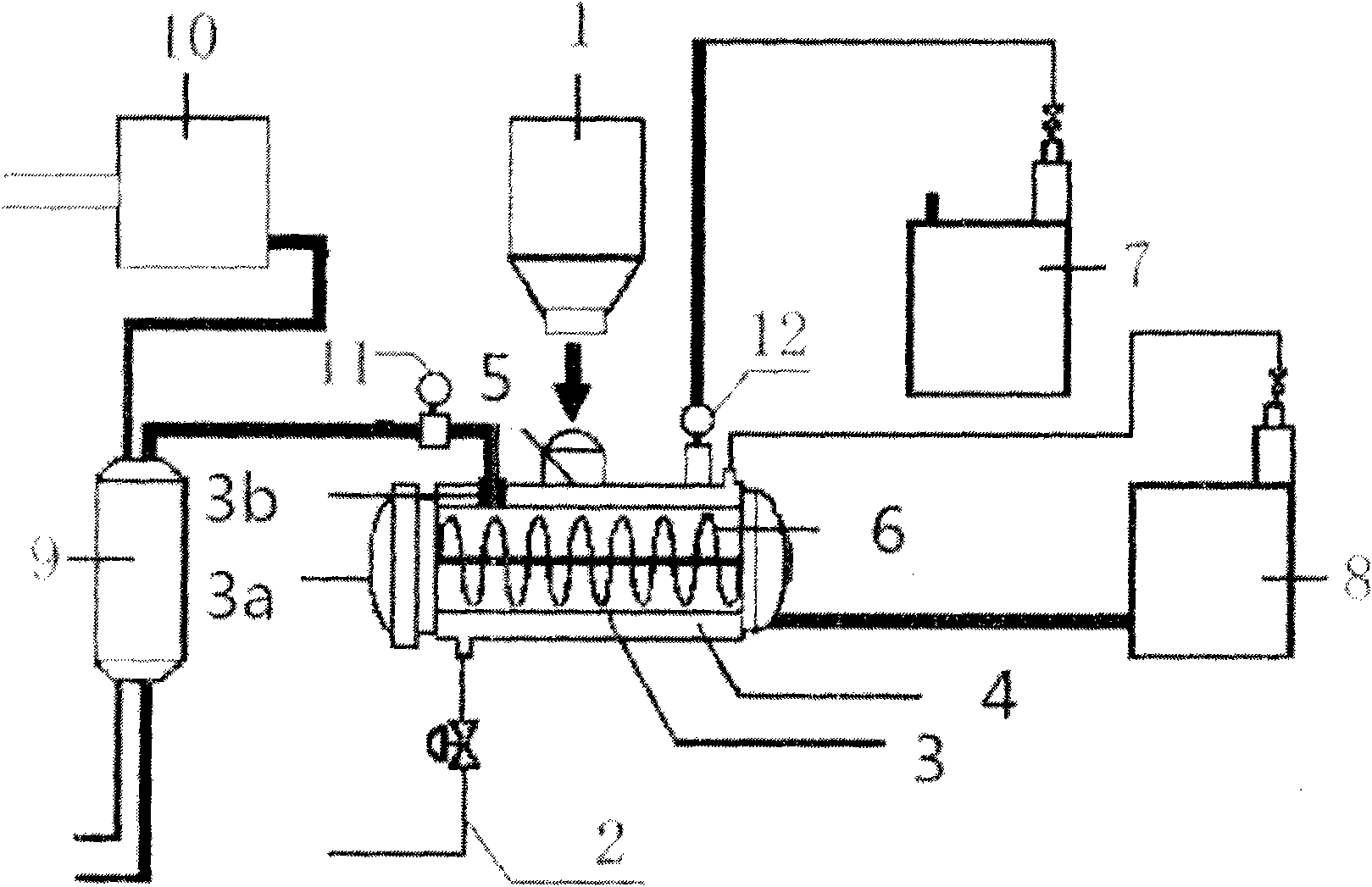

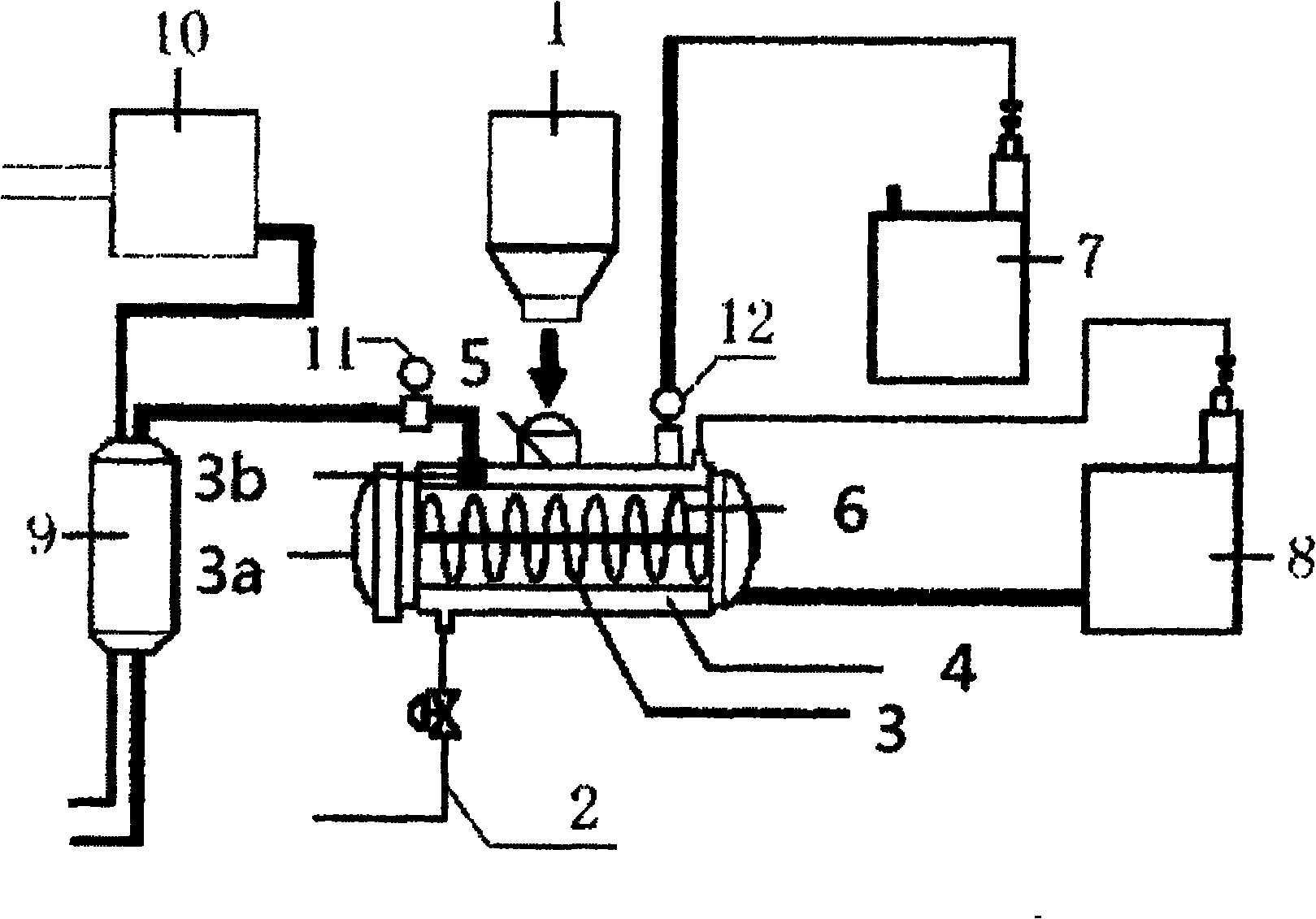

Medical waste subcritical hydrolysis processing apparatus

A technology for medical waste and treatment device, applied in the field of medical waste subcritical hydrolysis treatment device, can solve the problems of high maintenance cost of device equipment, large heat source consumption, and high energy consumption of the device, so as to solve the problem of disgust and achieve the effect of weight reduction Good, low impurity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] When the internal volume is selected as 3m 3 During the subcritical hydrolysis processor 3, 1.2 tons of medical waste and 0.8 tons of plant waste were dropped into it while stirring. After feeding is completed, the once-through steam boiler 7 (selecting fuel oil to generate a steam once-through boiler with a steam rate of 2 ton / hour) delivers steam to the inside of the subcritical hydrolysis processor 3, and the internal pressure and temperature of the subcritical hydrolysis processor 3 are respectively 0.9 MPa and 170°C. Afterwards, the organic heat carrier boiler 8 sends heat to the heating jacket 4 to 280° C. and heats the subcritical hydrolysis processor 3 . When the internal temperature and pressure of the subcritical hydrolysis processor 3 reach 200°C and 1.9Mpa respectively, the heating jacket 4 stops heat supply. After that, the heat is intermittently delivered to maintain the internal temperature of the processing container 3 at 220°C. The duration of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com