Unpowered independent deep-water operation pontoon inflating device and method

A technology of inflatable devices and buoys, which is applied to underwater operation equipment, hydrogen production, transportation and packaging, etc., can solve the problems of impossible construction of deep sea underwater platforms, so as to promote the progress of marine science, realize timing recovery, expand The effect of maritime strategic space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

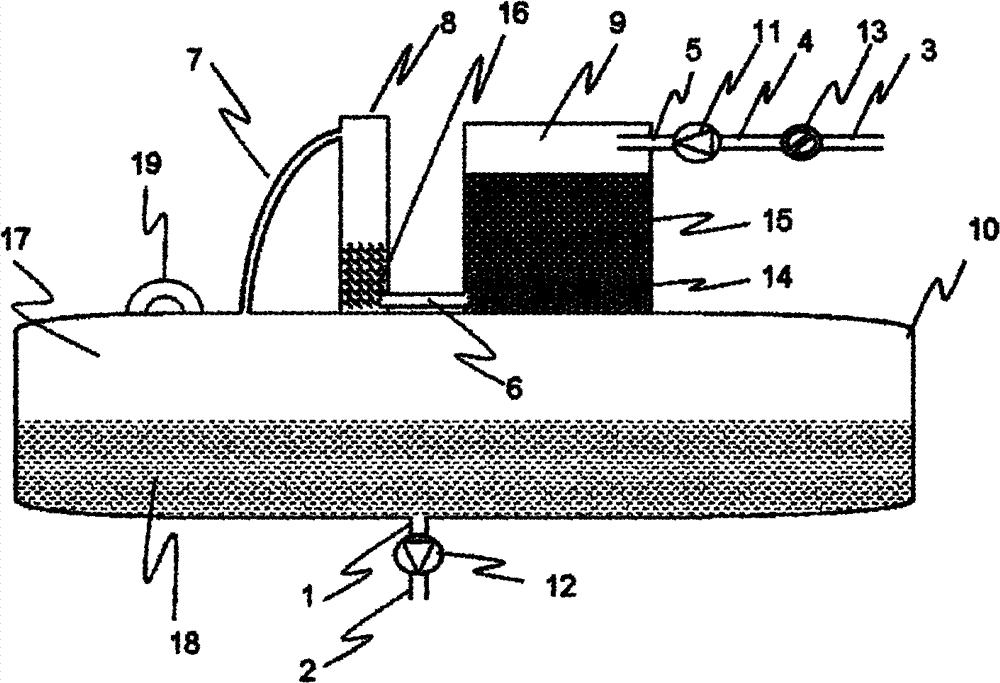

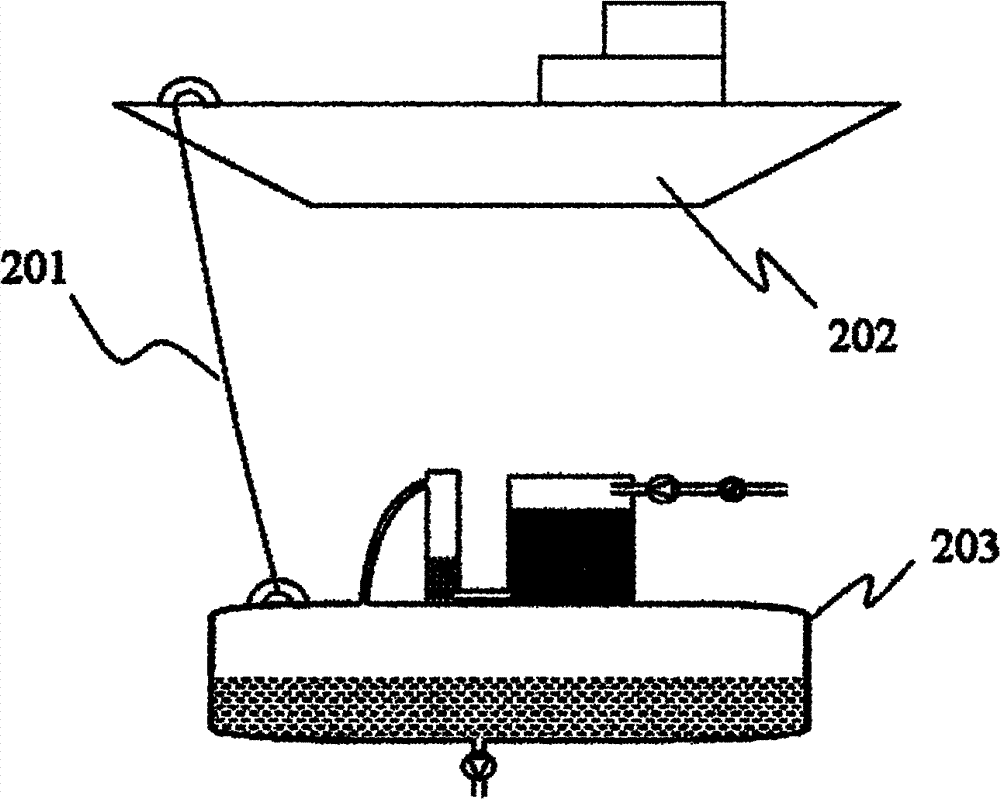

[0026] The present invention will be described in detail below according to the schematic diagram of the system device.

[0027] The buoy filling device of the present invention consists of a sodium borohydride container 9 and a tubular reactor 8 for storing sodium borohydride powder. The sodium borohydride container 9 top is provided with water inlet, and the bottom is provided with sodium borohydride solution outlet; The unlatching of opening valve 12 is controlled by mechanical timer and pressure; The bottom outlet of sodium borohydride container 9 is connected with tubular reactor 8 with conduit 6; The pressure opening valve 12 flows into the sodium borohydride container 9, and part of the sodium borohydride 15 dissolves to form a solution, which passes through the filter screen 14 and enters the tubular reactor 8 connected thereto from the outlet; the tubular reactor 8 is filled with porous three-dimensional The nickel catalyst 16 of the structure is either a cobalt cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com