Nitrogen oxide sensor chip

A sensor chip and nitrogen oxide technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of complex manufacturing process, unsuitable for large-scale production, and difficult connection of lead wires, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

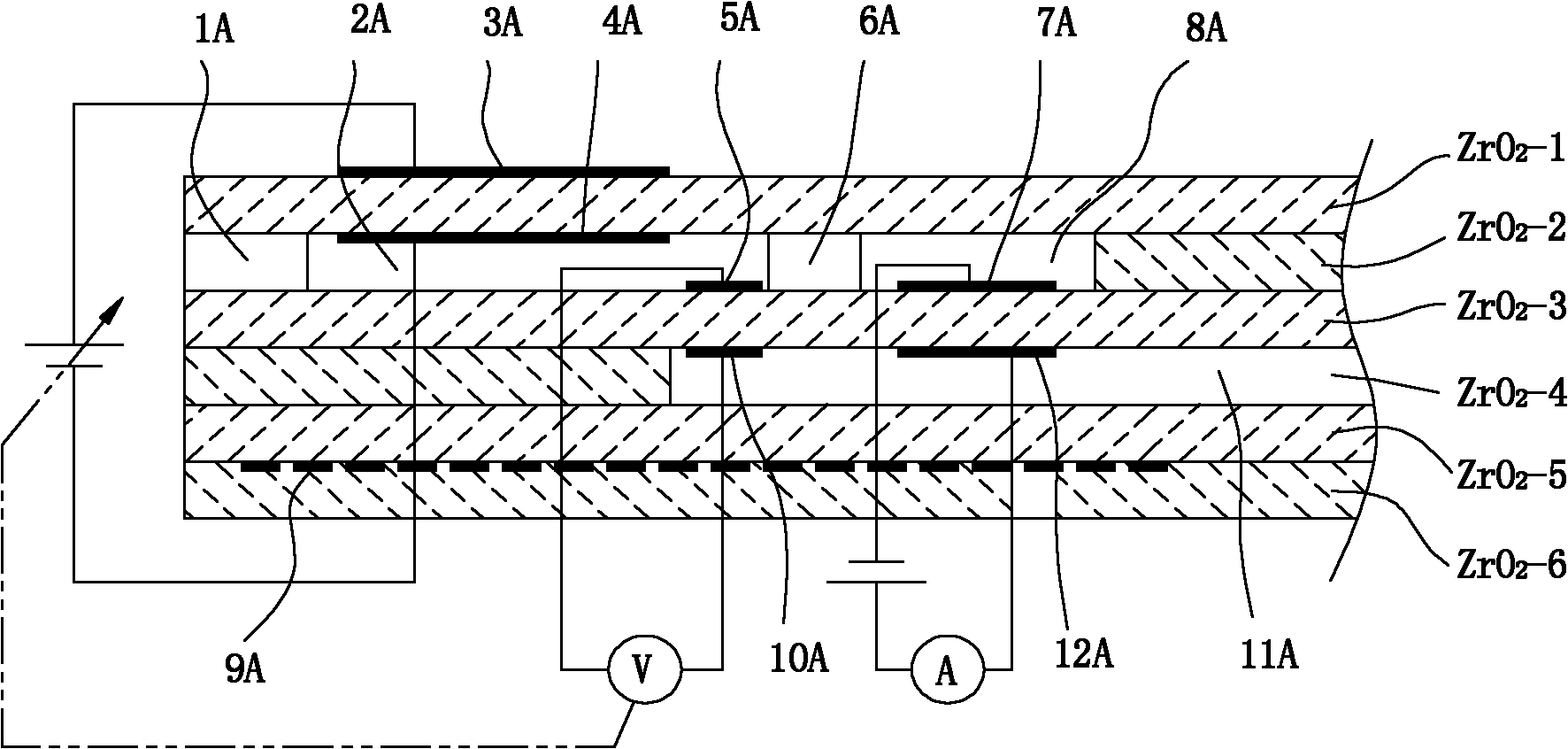

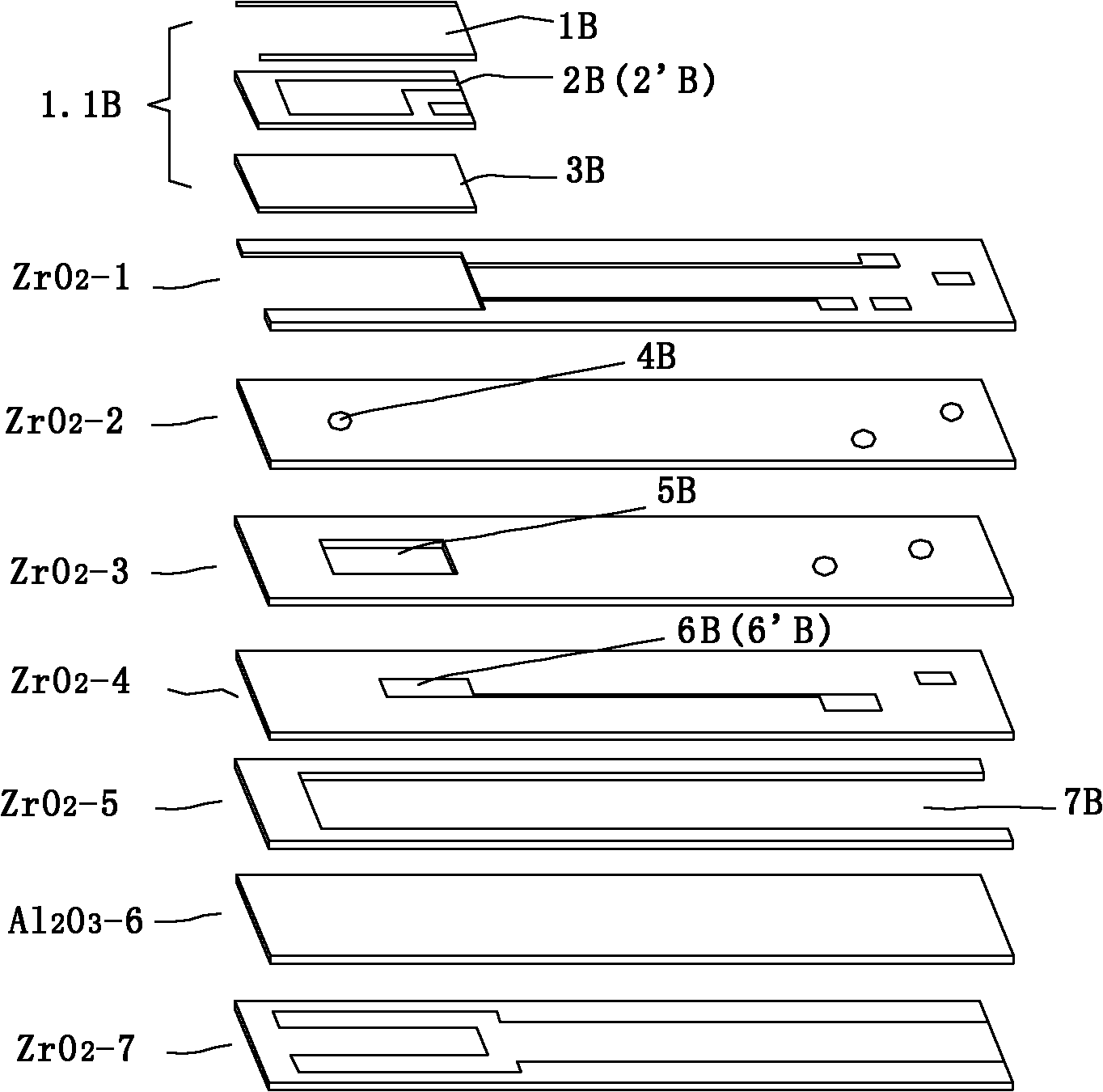

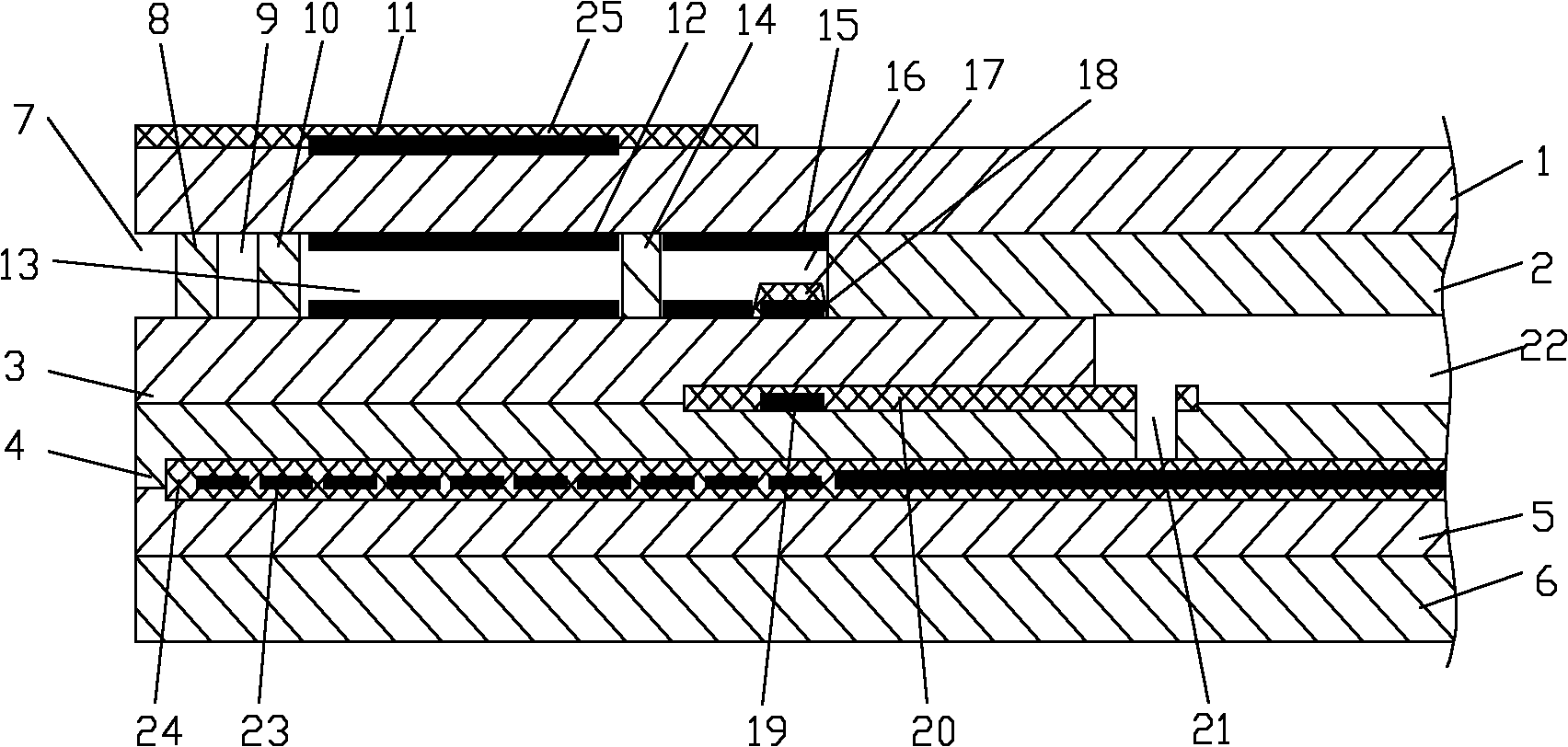

[0024] A nitrogen oxide sensor chip, which is formed by laminating the first layer to the sixth layer of substrates 1-6 of six layers of substrates, the materials of the six layers of substrates are all zirconia, and the second layer of substrate 2 includes four three cavities, the first cavity 7, the second cavity 9, the third cavity 13, and the fourth cavity 16, three columns of diffusion barrier layers 8, 10, 14 are respectively arranged in sequence between the four cavities, and the third cavity A first electrode 12 is provided in the cavity 13, a second electrode 15 and a third electrode 18 are provided in the fourth cavity 16, a reference gas channel 22 connected to the atmosphere is provided on the third substrate 3, and a third electrode 15 is provided in the fourth cavity 16. A reference electrode 19 is arranged between the layer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com