Method for enhancing packaging efficiency of solar module

A technology for solar modules and high efficiency, applied in electrical components, semiconductor devices, photovoltaic power generation, etc., can solve the problems of easy damage to the structure, impact on the service life of components, high cost and energy consumption, and achieve easy cleaning, enhanced film strength, and not easy to fall off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

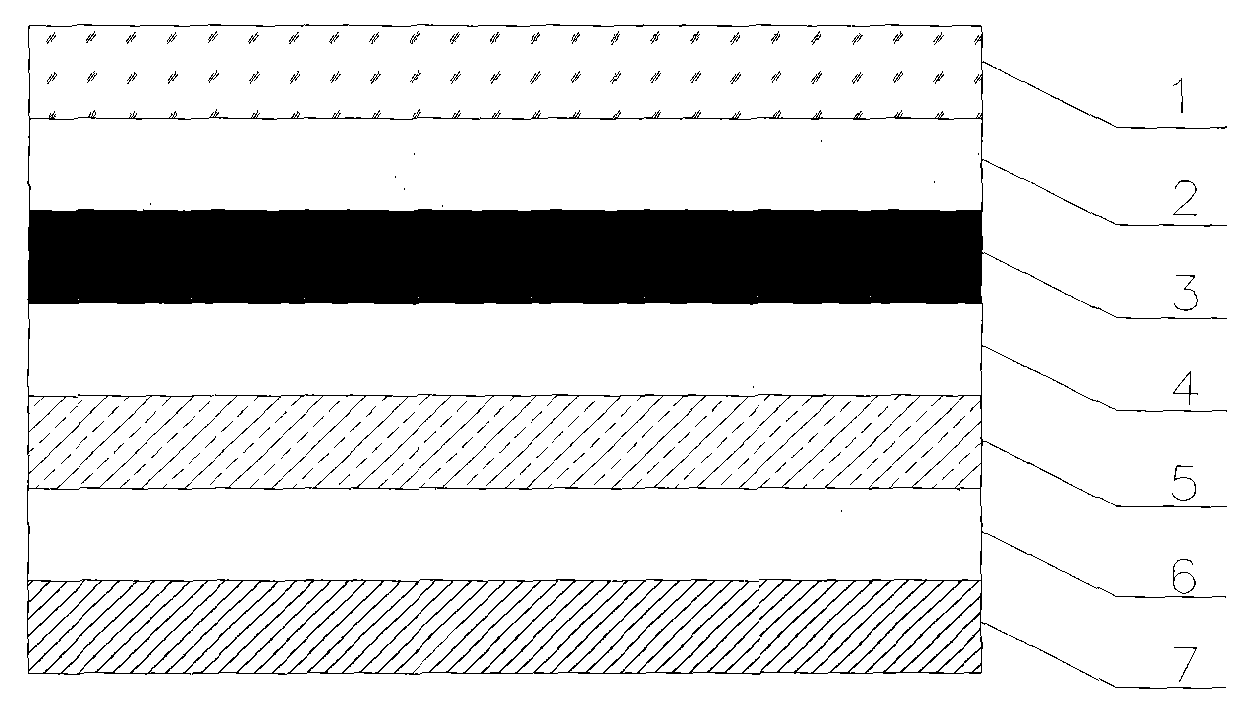

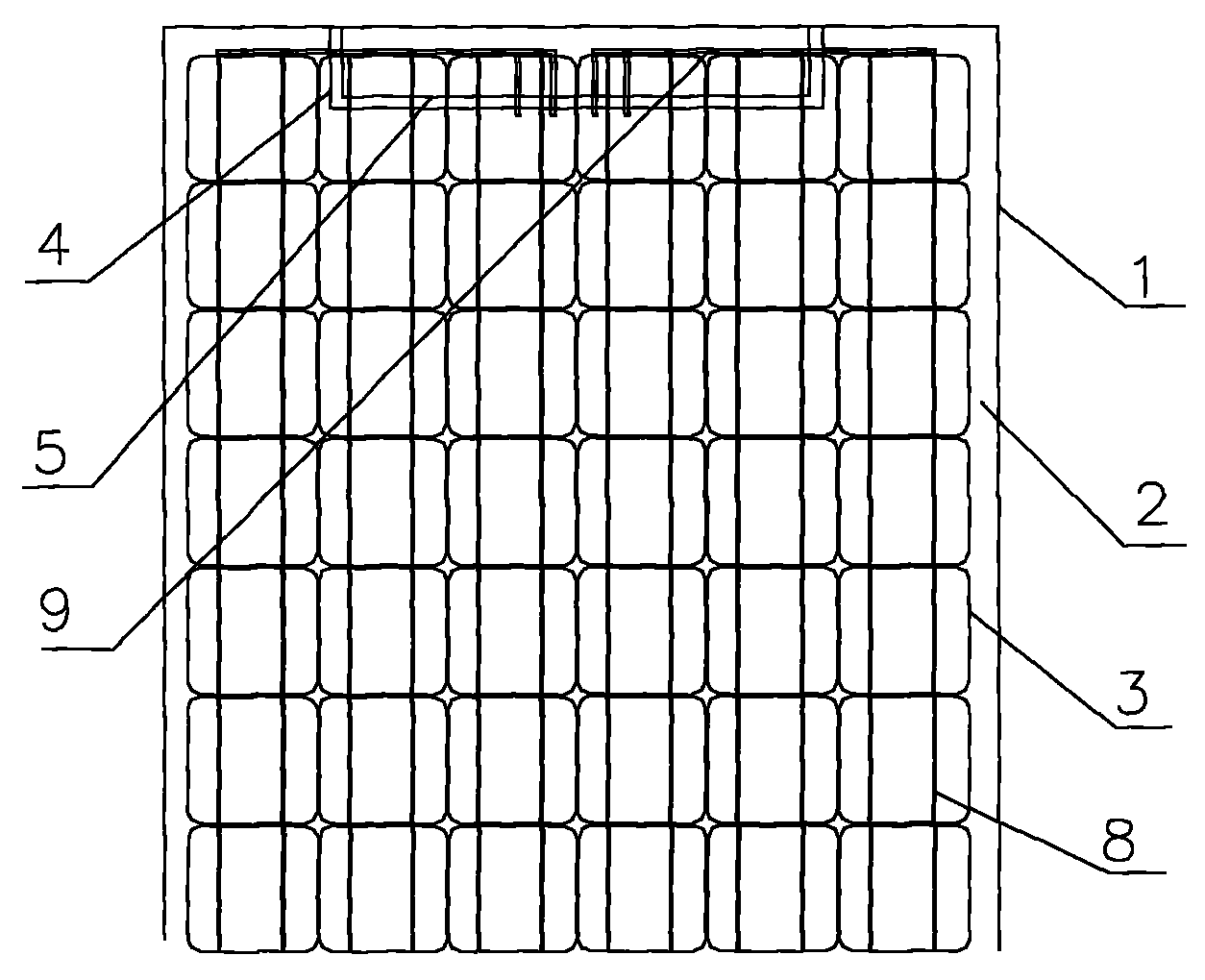

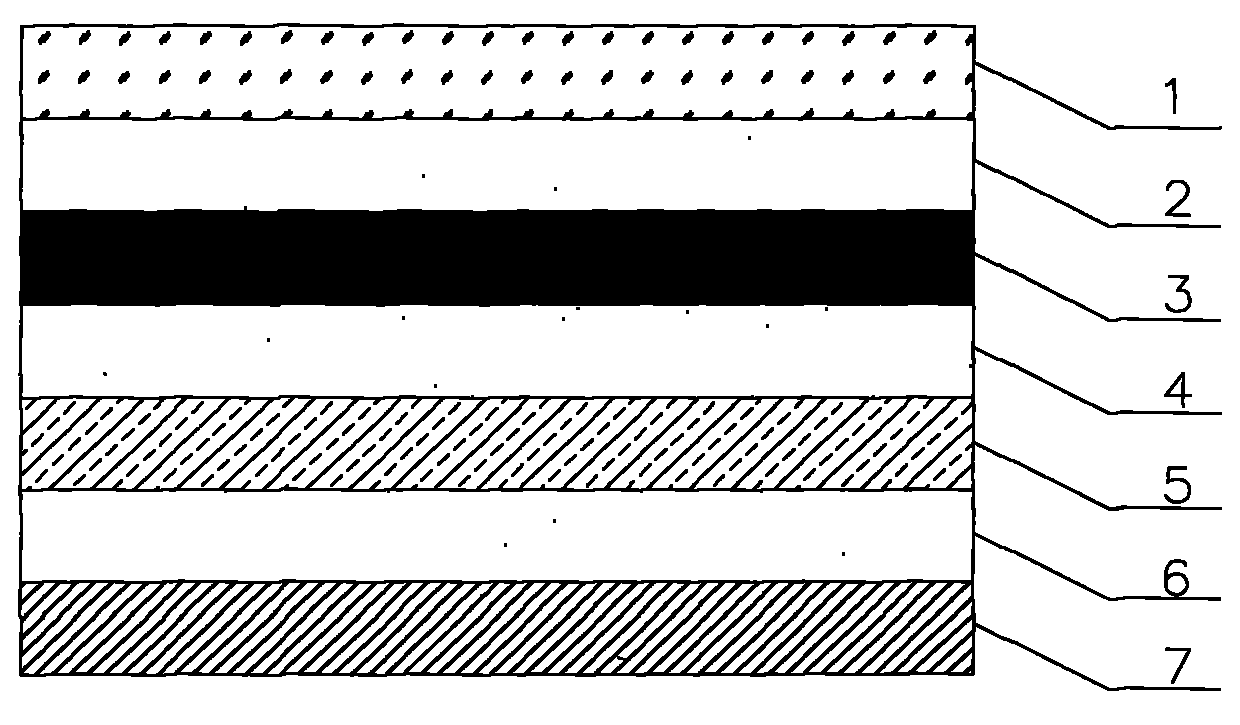

[0024] Such as figure 1 , figure 2 As shown, a method for improving the encapsulation efficiency of a solar module, the method includes a glass 1, a first EVA adhesive film 2, a battery sheet 3, an EVA cover strip 4, a spacer strip 5, and a second EVA glue from top to bottom. Film 6, back plate 7, the surface of the glass 1 is coated with a layer of anti-reflection film, the thickness is 1 / 4 of a certain wavelength λ, and when the refractive index is the square root of the product of the refractive index of air and glass, this anti-reflection film The reflectance of the light of this wavelength is 0, which greatly improves the light transmittance of the glass. The surface of the glass 1 is a rough surface, which improves the wettability of the surface, endows the surface with superhydrophilicity or superhydrophobicity, and makes the film have a self-cleaning function, so that the surface of the component is easy to clean. The components included in the method also include i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com