High-strength UOE steel pipe excellent in earthquake-proof performance and in low-temperature toughness of weld heat-affected zone

A steel pipe, yield strength technology, applied in the field of high-strength UOE steel pipe, can solve the problem that the seismic performance requirements have not been established, and achieve the effect of excellent low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The present invention will be described in more detail with reference to examples.

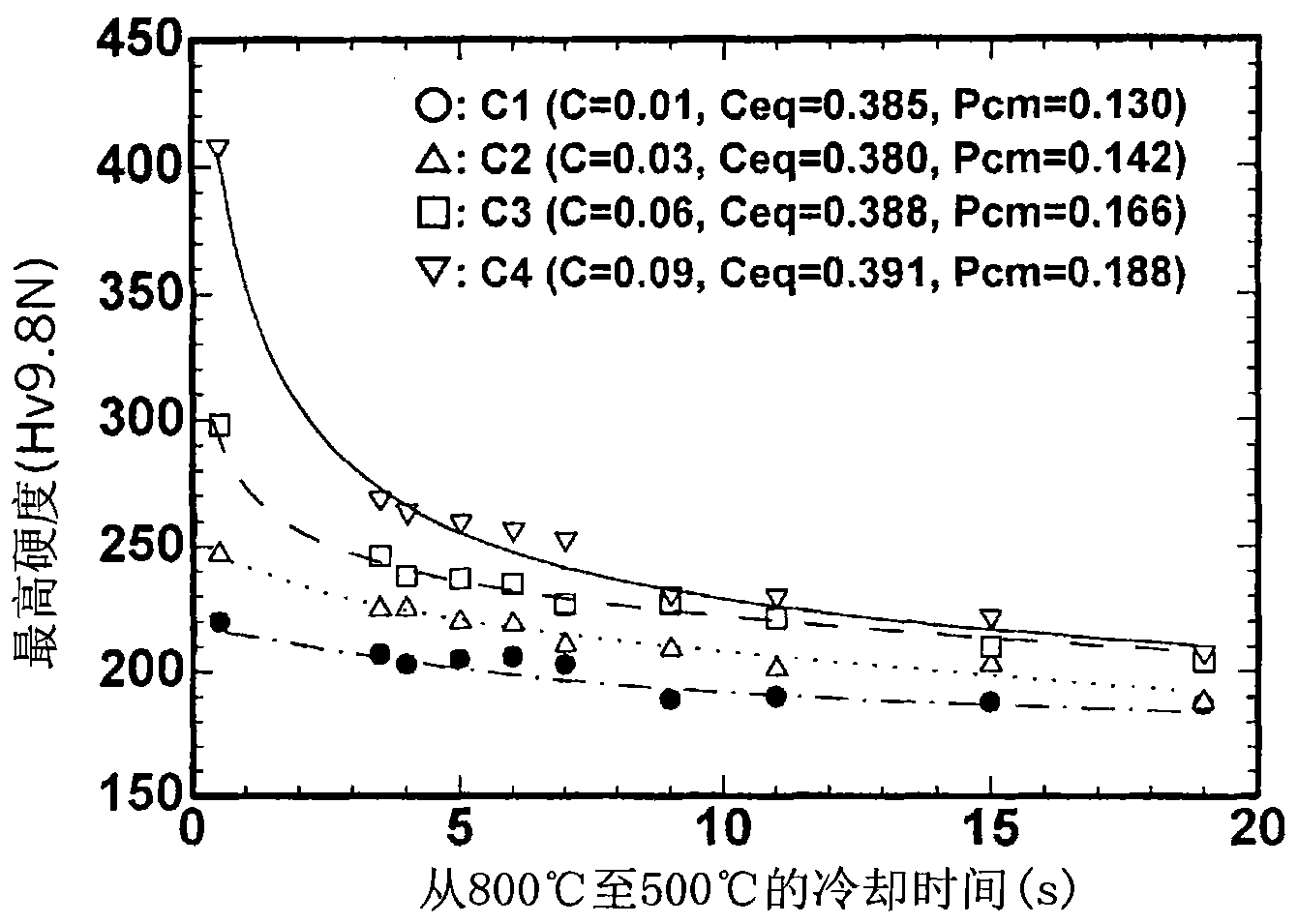

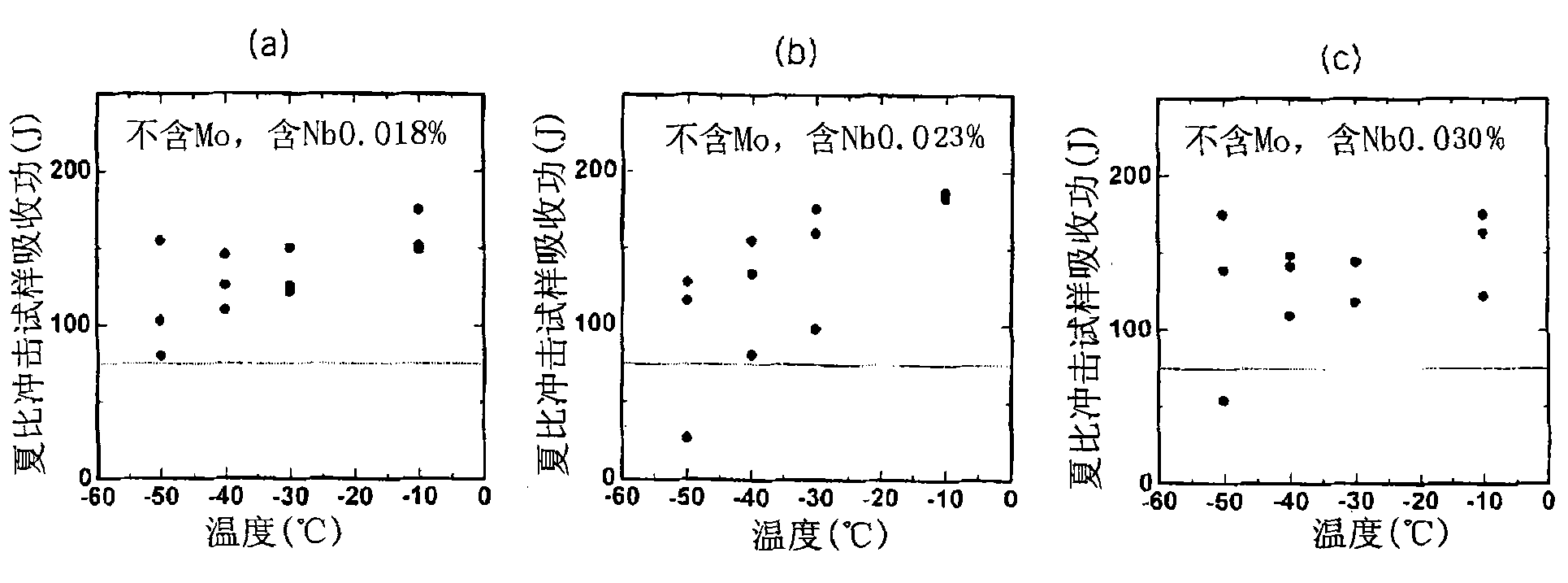

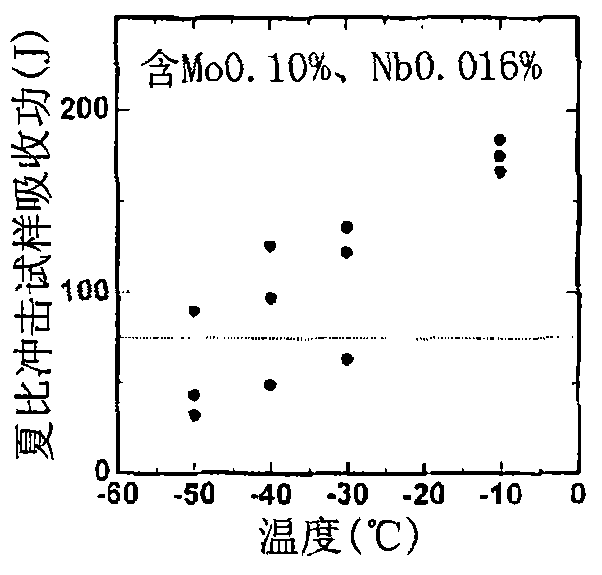

[0073] Using UOE forming, the thickness of steel having the composition shown in Table 1 (other than that shown in Table 1 is Fe and impurities, B is not added, and the content of B as impurities is 0.0001%) and hardenability index Pcm The plate steel plate is formed in a cylindrical shape. Then, submerged arc welding is used to weld the butt joint once from the inner surface and the outer surface respectively, so as to manufacture a UOE steel pipe with an outer diameter of 30-56 inches and a wall thickness of 20-38 mm. The plate thickness is adjusted so that the welded portion of the outer surface and the welded portion of the inner surface have an overlapping portion of 3 mm to 30 mm, and welded.

[0074] Then, the mechanical properties (yield strength YS (MPa), tensile strength TS (MPa), yield ratio YR (%)) of the base metal of the above-mentioned UOE steel pipe, and the absorbed en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com