Flow field turbulator

A spoiler and flow field technology, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of catalyst sinking and accumulation, less catalyst storage, and lower product quality, and achieve the benefits of gas-liquid-solid three-phase The effect of separation, simple equipment structure and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

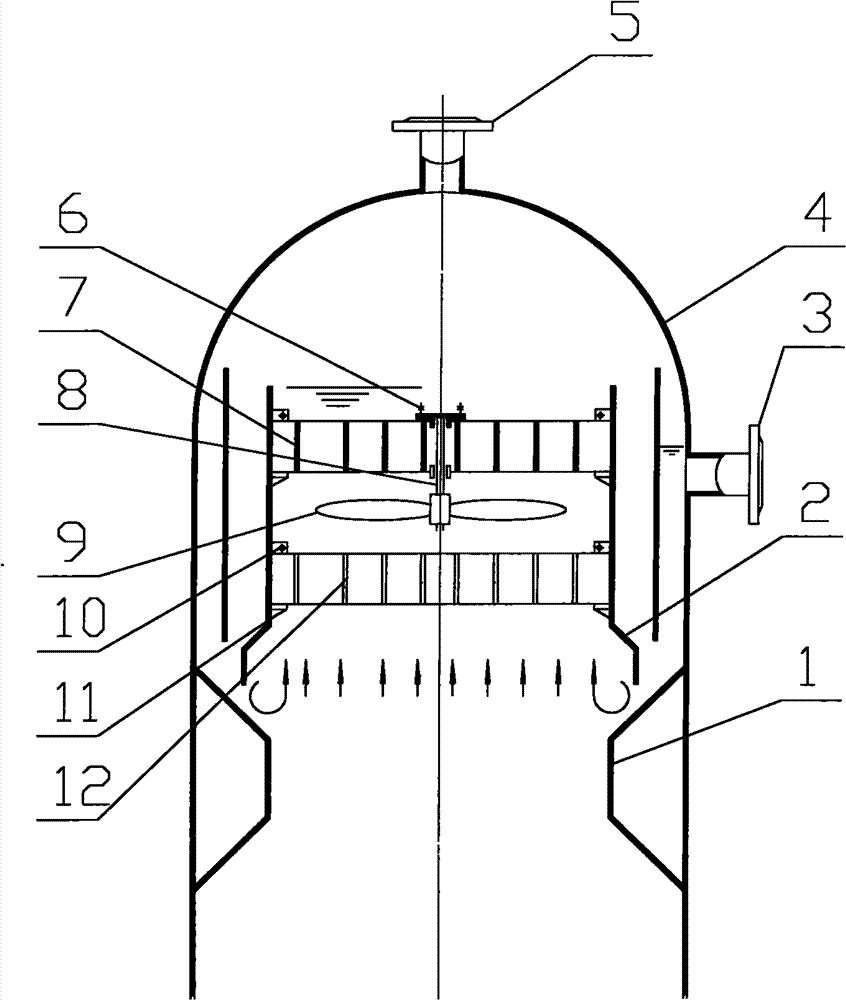

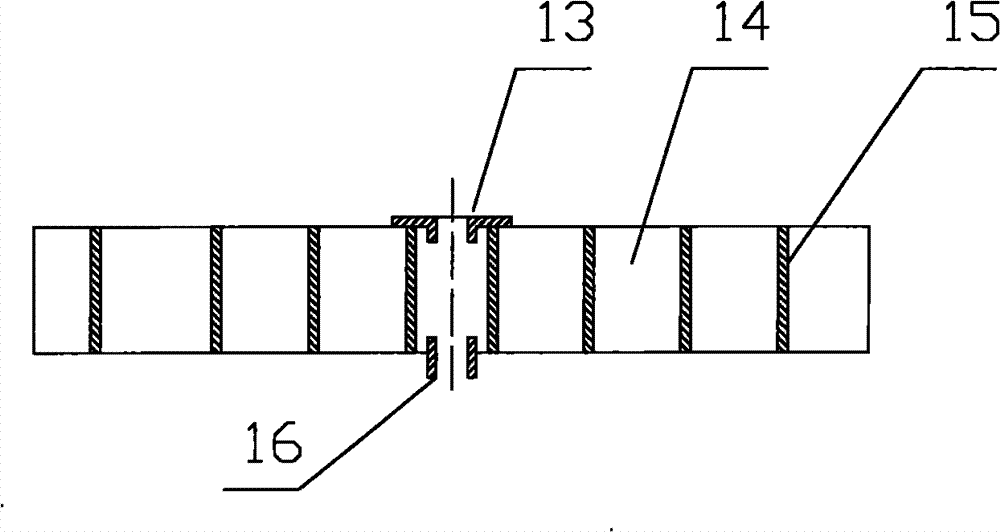

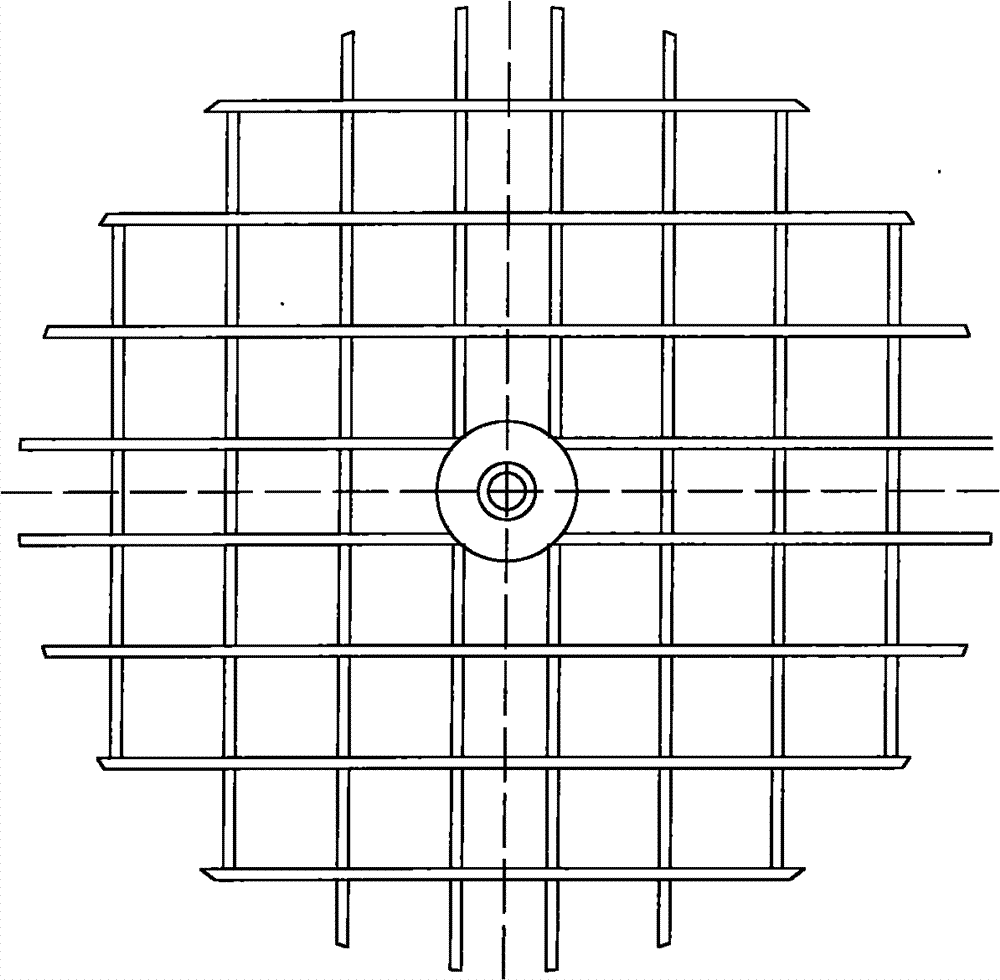

[0018] The flow field spoiler of the present invention will be further described in detail below with reference to the accompanying drawings.

[0019] According to an embodiment provided by the present invention, the turbulence device of the present invention can be used in an ebullated bed reactor. Such as figure 1 As shown, the flow field spoiler of the present invention includes a guide body 1, a fastener 6, a guide grid 7, an agitator arm 8, a propulsion agitator 9, a pin 10, a grid support 11 and a rectifying grid Grille 12; Stirrer arm is fixed on the center of deflector grille; Push-type stirrer 9 is installed on stirrer arm 8 lower ends; As figure 2 , 3 As shown, the diversion grid 7 includes a grid plate, an agitator arm seat 13 and a positioning sleeve 16, and the grid plate is formed by a set of ribs 14 of equal height and parallel and a set of partition plates 15 of equal height and parallel. The rectifying grid 12 is also formed by a group of equal height and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com