Preparation method of ultra-thick titanium/steel composite tube plate with large area and high properties

A high-performance, composite pipe technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of large format, thick cladding, and difficulty in implementing tailor-made welding processes, and achieve the effects of cost saving and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

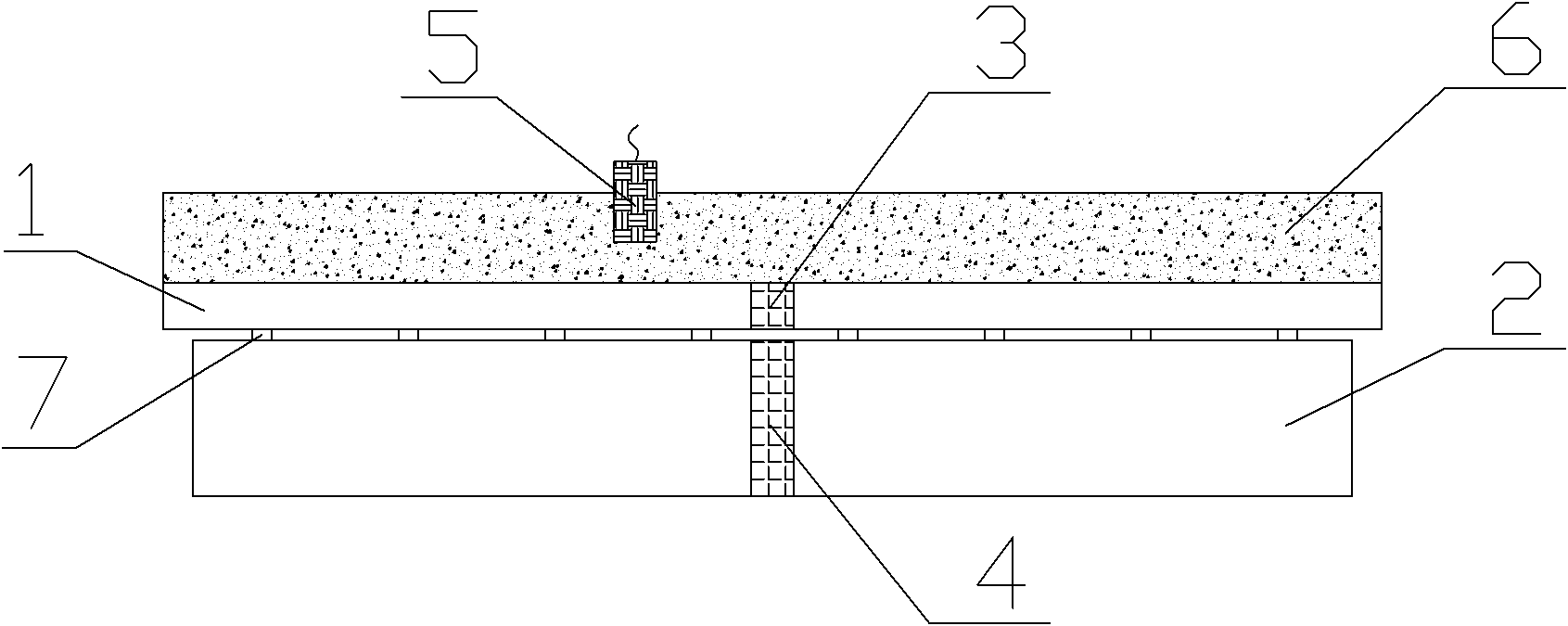

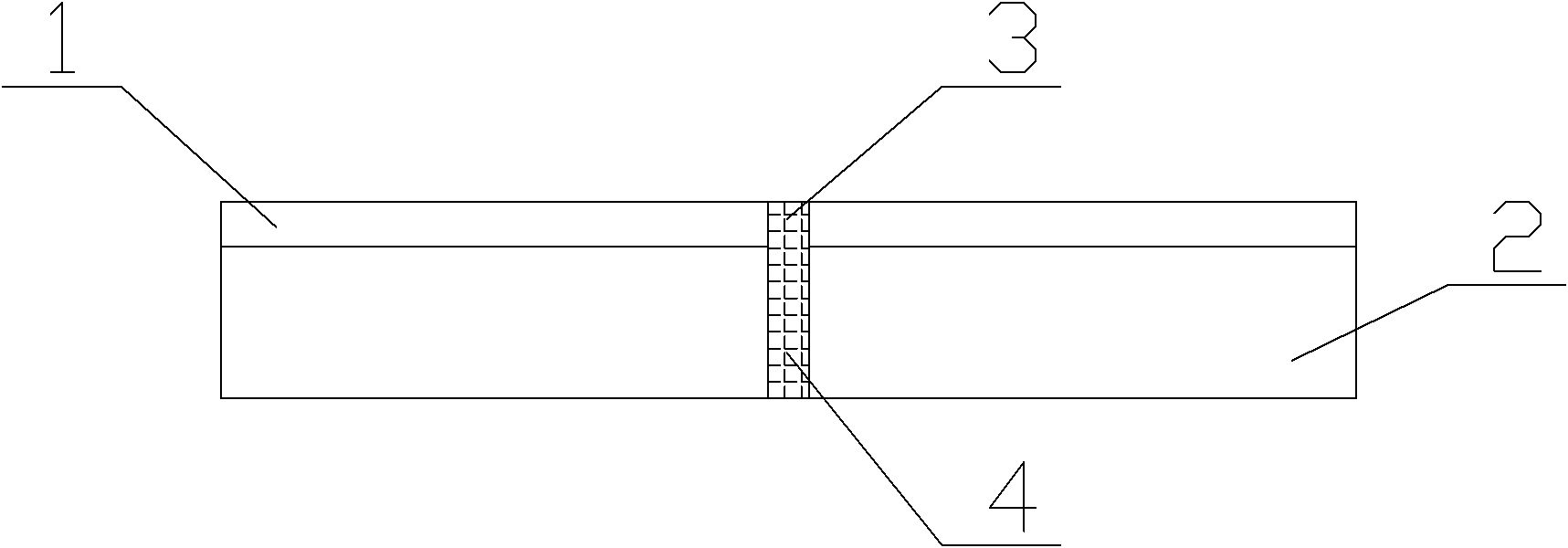

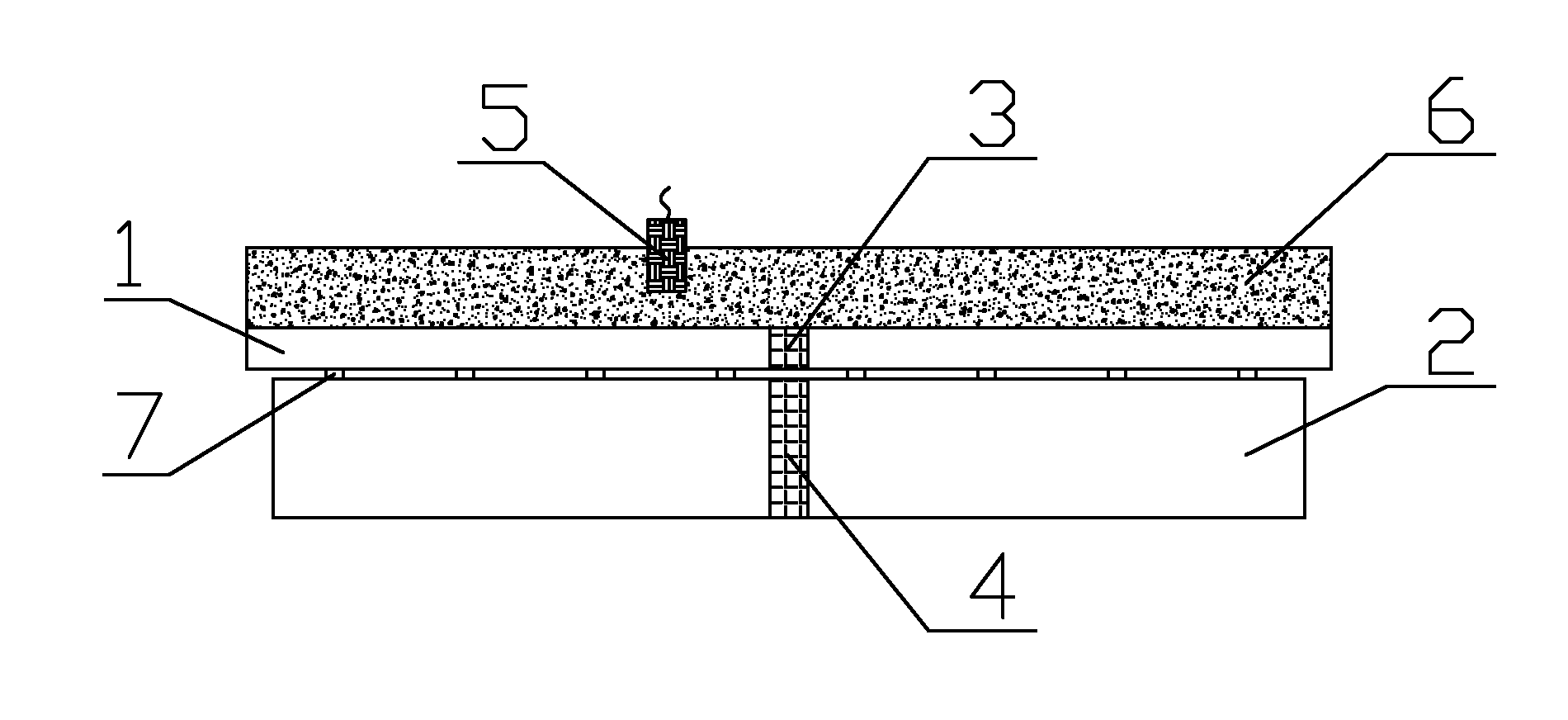

[0029] Step 1, adopting the method of TIG welding to carry out tailor-welding treatment to a plurality of titanium plates with a thickness of 8 mm to prepare a multi-layer titanium plate 1 with a weld seam-3 having a width of 340 mm and a length of 1120 mm;

[0030] Step 2, adopting the method of automatic submerged arc welding to carry out tailor welding process on a plurality of steel plates with a thickness of 200 mm to prepare a base steel plate 2 with a weld seam 2 4 with a width of 320 mm and a length of 1100 mm;

[0031] Step 3, leveling the base steel plate 2 to make its unevenness ≤ 6mm / m;

[0032] Step 4: Grinding the bonded surface of the clad titanium plate 1 and the leveled base steel plate 2 to a roughness Ra≤10 μm;

[0033] Step 5: Evenly arrange a plurality of gap materials 7 with a height of 2mm on the polished base steel plate 2, then place the polished multi-layer titanium plate 1 on the gap material 7, and keep the welding seam 3 and the welding seam. Seam...

Embodiment 2

[0038] Step 1, adopting the method of TIG welding to carry out tailor-welding treatment to a plurality of titanium plates with a thickness of 20 mm to prepare a multi-layer titanium plate 1 with a weld seam-3 having a width of 5200 mm and a length of 6700 mm;

[0039] Step 2, adopting the method of automatic submerged arc welding to carry out tailor welding process on a plurality of steel plates with a thickness of 100 mm to prepare a base steel plate 2 with a weld seam 2 4 with a width of 5100 mm and a length of 6600 mm;

[0040] Step 3, leveling the base steel plate 2 to make its unevenness ≤ 6mm / m;

[0041] Step 4: Grinding the bonded surface of the clad titanium plate 1 and the leveled base steel plate 2 to a roughness Ra≤10 μm;

[0042] Step 5: Evenly arrange a plurality of gap materials 7 with a height of 8mm on the polished base steel plate 2, then place the polished multi-layer titanium plate 1 on the gap material 7, and keep the welding seam 3 and the welding seam. S...

Embodiment 3

[0047] Step 1, adopting the method of TIG welding to carry out tailor-welding treatment to a plurality of titanium plates with a thickness of 14 mm to prepare a multi-layer titanium plate 1 with a weld seam-3 having a width of 2800 mm and a length of 3900 mm;

[0048] Step 2, adopting the method of automatic submerged arc welding to carry out tailor welding process on a plurality of steel plates with a thickness of 150 mm to prepare a base steel plate 2 with a weld seam 2 4 with a width of 2740 mm and a length of 3840 mm;

[0049] Step 3, leveling the base steel plate 2 to make its unevenness ≤ 6mm / m;

[0050] Step 4: Grinding the bonded surface of the clad titanium plate 1 and the leveled base steel plate 2 to a roughness Ra≤10 μm;

[0051] Step 5: Evenly arrange a plurality of gap materials 7 with a height of 15 mm on the polished base steel plate 2, then place the polished multi-layer titanium plate 1 on the gap material 7, and keep the welding seam-3 and the welding seam. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com