Method for producing resin sheet transferring surface shape

A manufacturing method and surface shape technology are applied in the manufacturing field of surface shape transfer resin sheets, which can solve problems such as difficulty in obtaining optical properties, and achieve the effects of good manufacturing efficiency, good manufacturing efficiency, and good manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (Manufacturing device A)

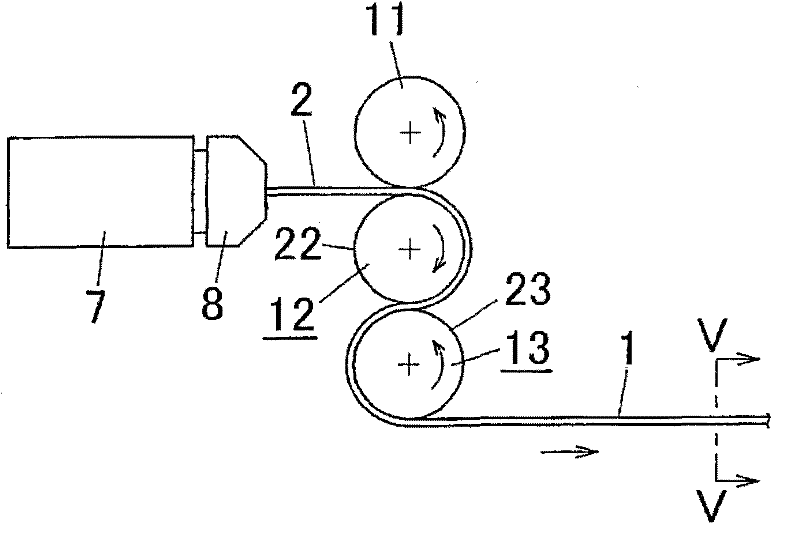

[0077] get ready figure 1 Manufacturing apparatus A of the structure shown. This manufacturing apparatus A has an extruder 7 having a die 8 , a first squeeze roll 11 , a second squeeze roll 12 , and a third squeeze roll 13 . The surface of the first squeezing roller 11 is a mirror surface.

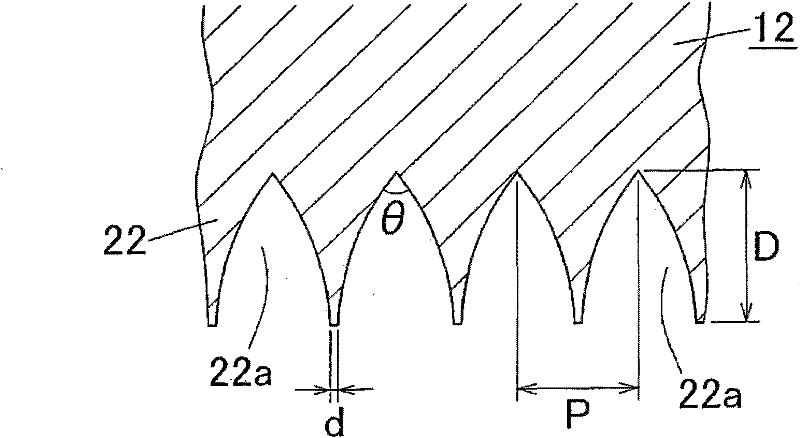

[0078] In the transfer mold 22 on the surface of the second squeeze roller 12, the pitch interval P of the groove 22a is 100 μm, the depth D of the groove 22a is 146.3 μm, D / P=1.46, the interval d is 4.7 μm, and the angle θ is 74° (refer to figure 2 ).

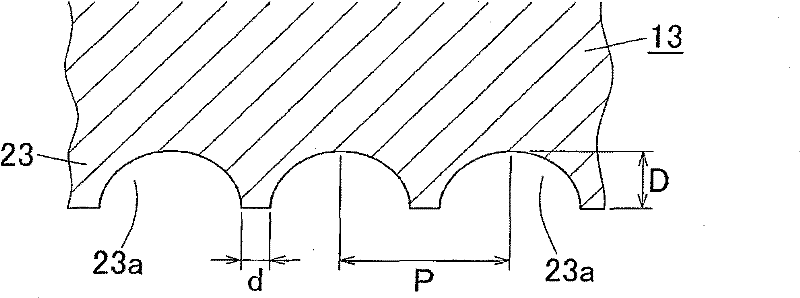

[0079] And, in the transfer mold 23 on the surface of the third squeeze roller 13, the pitch interval P of the groove 23a is 400 μm, the depth D of the groove 23a is 220 μm, D / P=0.55, and the interval d is 4.6 μm (refer to image 3 ).

[0080] Propylene-ethylene random copolymer resin ("D101" manufactured by Sumitomo Chemical Co., Ltd., propylene unit content rate 99% by mass) (crystalline resin) 88...

Embodiment 2

[0106] (Manufacturing device B)

[0107] Prepare figure 1 Manufacturing apparatus B of the structure shown. This manufacturing apparatus B has an extruder 7 having a die 8 , a first squeeze roll 11 , a second squeeze roll 12 , and a third squeeze roll 13 . The surfaces of the first squeeze roll 11 and the second squeeze roll 12 are mirror surfaces.

[0108] In the transfer mold 23 on the surface of the third squeeze roller 13, the pitch interval P of the groove 23a is 353 μm, the depth D of the groove 23a is 223.7 μm, D / P=0.63, and the interval d is 2.0 μm (refer to Figure 5 (a)).

[0109] 100 parts by weight of polycarbonate resin (Calibur 200-30 manufactured by Sumitomo Dow Co., Ltd.) was melted and kneaded at 220° C. to 255° C. in the extruder 7 with a screw diameter of 40 mm in the above-mentioned manufacturing apparatus B, and then passed through a multi-flow machine with a width of 250 mm. The continuous resin sheet 2 was obtained by extruding in a sheet form at a d...

Embodiment 3

[0126] 100 parts by weight of acrylic resin (Sumipex EXN manufactured by Sumitomo Chemical Co., Ltd.) was melted and kneaded at 200° C. to 245° C. in the extruder 7 with a screw diameter of 40 mm in the above-mentioned manufacturing apparatus B, and then passed through a multi-manifold die with a width of 250 mm. 8. Extrude in a sheet form at a die temperature of 235° C. to obtain a continuous resin sheet 2 (extrusion process).

[0127] Then, if figure 1 As shown, the continuous resin sheet 2 is passed between the first squeeze roll 11 and the second squeeze roll 12 of the above-mentioned manufacturing apparatus B, and after the continuous resin sheet 2 is squeezed by the two squeeze rolls 11 and 12 (first Extrusion step), the continuous resin sheet 2 is conveyed in a state of being in close contact with the outer peripheral surface of the second squeeze roll 12 (transportation step), and then the continuous resin sheet 2 is passed through the second squeeze roll 12 and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com