Wiring member, resin-coated metal part and resin-sealed semiconductor device, and manufacturing method for the resin-coated metal part and the resin-sealed semiconductor device

A technology for metal parts and manufacturing methods, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, and semiconductor/solid-state device components, etc., can solve the problems of reduced manufacturing efficiency, inability to obtain luminous efficiency, and inability to perform plating processing, etc. The effect of improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0091] 1. Structure of semiconductor device

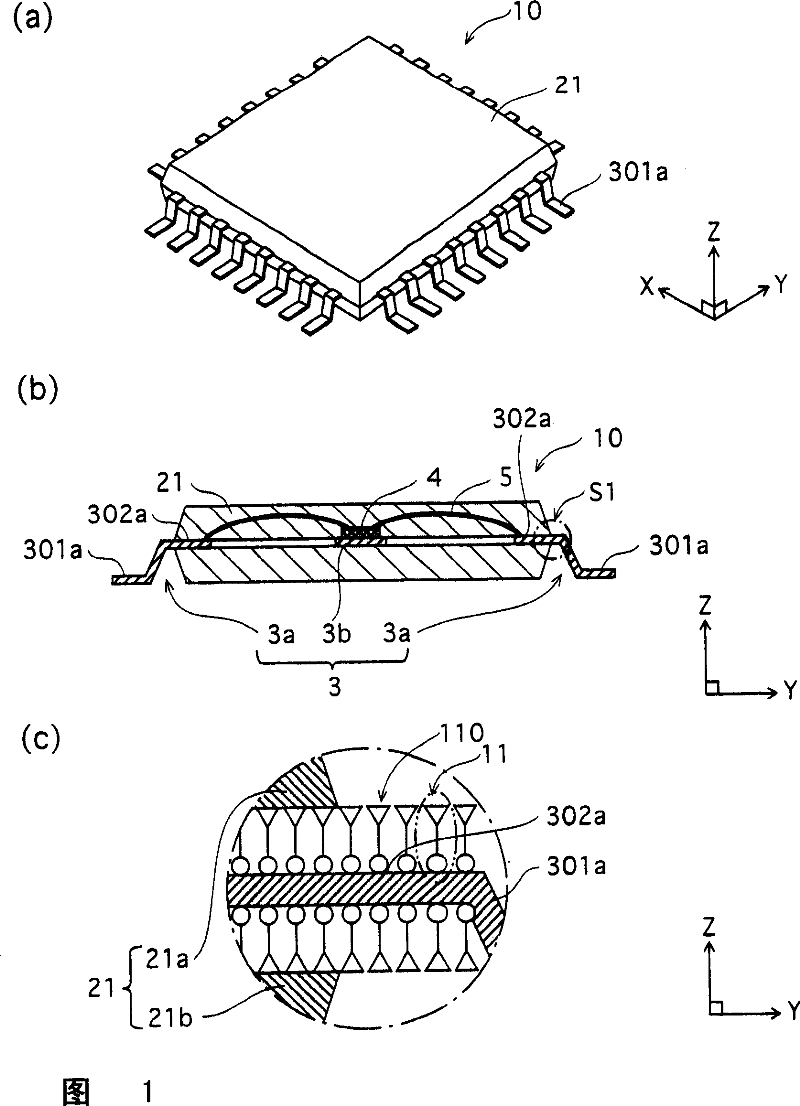

[0092] FIG. 1( a ) is an external perspective view showing the structure of a semiconductor device (QFP: Quad Flat Package 10 ) as an applied example of the present invention. Figure 1(b) is a yz cross-sectional view of QFP10. Fig. 1(c) is an enlarged view of the S1 portion in Fig. 1(b).

[0093] The QFP 10 is a surface mount type semiconductor device used for IC, LSI, etc., and includes a semiconductor chip 4, wiring leads 3, wires 5, molding resin 21, and the like.

[0094] The wiring lead 3 is made of a metal material having excellent electrical conductivity (copper alloy is mentioned as an example), and is made of a combination of chip pads 3 a and 3 b formed by pressing a metal plate.

[0095] QFP10 is a surface mount type semiconductor device, as shown in Figure 1 (a), has the following structure: a plate-shaped molding resin 21 having a square main surface with a certain thickness is formed, and extends from its periphery ...

Embodiment approach 2

[0158] As described above, various effects can be exhibited by applying the organic film 110 composed of functional organic molecules 11 according to Embodiment 1 to a semiconductor device, but this is only an example, and the presence of a semiconductor chip is not essential. For example, it can be applied to an LED device having a light emitting diode element (LED) other than a semiconductor chip.

[0159] 7 is a schematic cross-sectional view showing the configurations of the wiring lead portion 30 and the reflector 22 of an LED device unit 31x according to Embodiment 2 of the present invention.

[0160] In this cross-sectional shape, the device unit 31x has a structure in which the wiring lead portion 30 is provided at the bottom of the mortar-shaped reflector 22 . The reflector 22 is formed by resin molding using a thermosetting resin material (epoxy resin or the like).

[0161] In such a device unit 31x, as in the first embodiment, the problem of resin burrs also occurs...

Embodiment approach 3

[0168] Embodiment 3 of the present invention will be described focusing on differences from Embodiment 2. FIG.

[0169] (Structure of LED device)

[0170] 8 is a cross-sectional view showing the structure and manufacturing steps of an LED device 31 according to Embodiment 3 of the present invention.

[0171] The basic structure of this LED device 31 includes a device unit 31x according to Embodiment 2, and as shown in FIG. The LED chip 42 is connected to the wiring lead portion 30 through a wire 53 .

[0172] In order to seal the LED chip 42 and the like, the reflector surface 201 and the exposed regions 301 and 302 in the reflector 22 are filled with a transparent sealing resin 82 .

[0173] Here, as the sealing resin 82, silicone resin which is an example of a thermosetting resin is used.

[0174] Here, in Embodiment 3 of the present invention, the organic film 120 composed of a monomolecular film formed by self-organization of the functional organic molecules 12 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com