Method for preparing WO3 nanocrystalline

A nanocrystal and nanoparticle technology, applied in the field of preparation of WO3 nanocrystal materials, can solve problems such as difficulty in large-scale production and complexity, and achieve the effects of low cost, easy operation, and simple and safe preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Preparation of polytungstic acid polyperoxide precursor: prepare polytungstic acid polyperoxide solution by reacting 5.4g tungsten powder with 40ml 30% hydrogen peroxide solution;

[0018] (2) Preparation of polyperoxytungstic acid composite sol with added surfactant: Weigh 3g of P123 (average molecular weight is 5800) and dissolve it in absolute ethanol, add to the W-containing solution prepared in (1) 6+ 0.01mol polyperoxytungstic acid solution, and reflux at 80°C for 2 hours to fully compound, and finally obtain a slightly viscous dark blue composite sol;

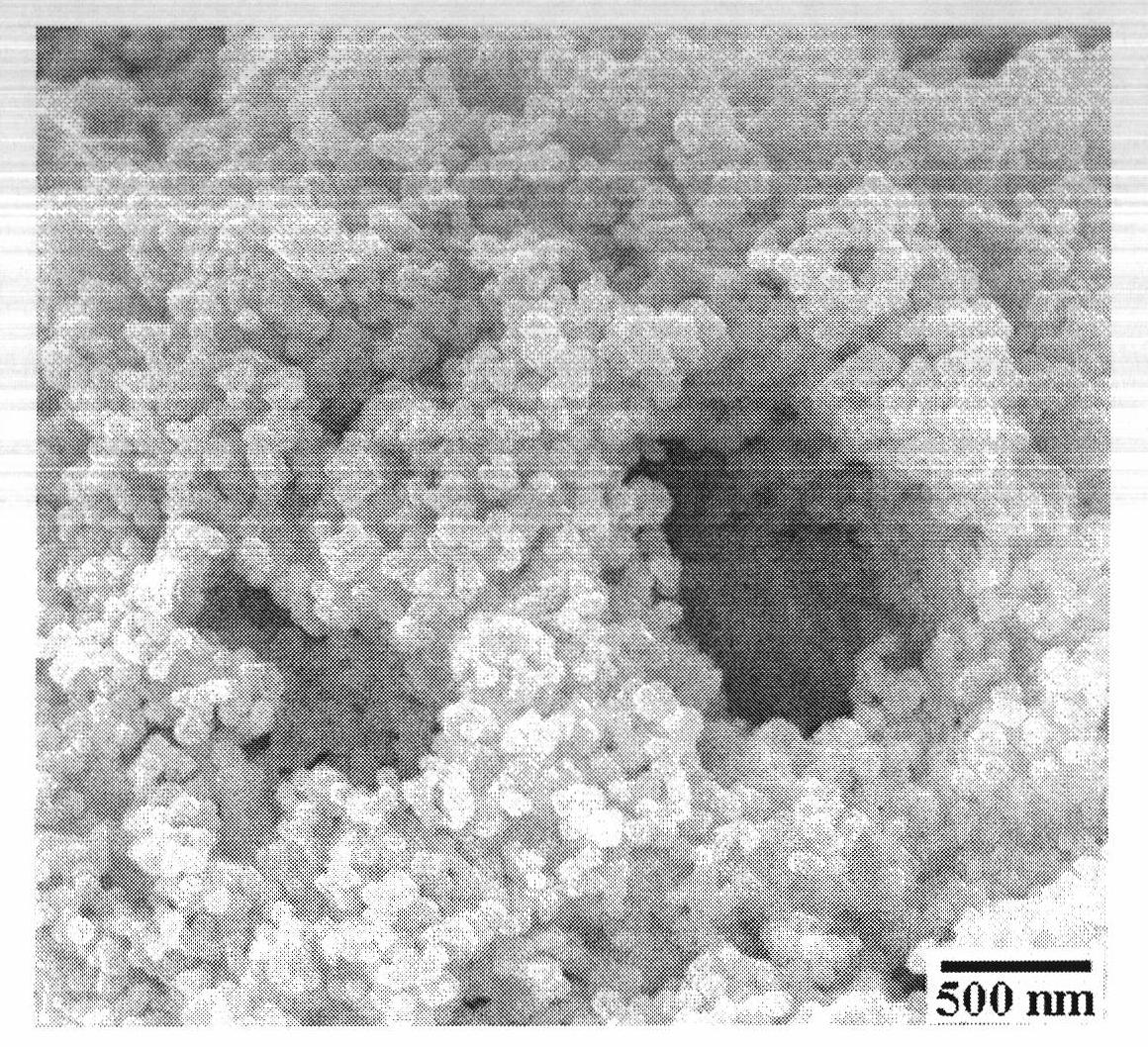

[0019] (3) WO 3 Preparation of nanocrystals: the composite sol prepared in (2) is poured into Al 2 o 3 In the crucible, it is annealed and calcined at 450°C in a muffle furnace to completely burn off the organic matter, and finally the light yellow-green WO 3 nanoparticles.

Embodiment 2

[0021] (1) Preparation of polyperoxytungstic acid precursor: with 7g WO 3 The powder was reacted with 50ml 30% hydrogen peroxide solution to prepare polyperoxytungstic acid solution;

[0022] (2) Preparation of polyperoxytungstic acid composite sol with added surfactant: and weigh 5g of PVP (the average molecular weight is 10000) and dissolve it in absolute ethanol, add it to the W-containing solution prepared in (1). 6+ 0.01mol polytungstic acid polyperoxide solution, and reflux at 100°C for one hour, and finally a slightly viscous dark blue composite sol was obtained;

[0023] (3) WO 3 Preparation of nanocrystals: the composite sol prepared in (2) is poured into Al 2 o 3 In the crucible, it is annealed and calcined at 600°C in a muffle furnace to completely burn off the organic matter, and finally the light yellow-green WO 3 nanoparticles.

Embodiment 3

[0025] (1) Preparation of polyperoxytungstic acid precursor: with 6g WO 3 The powder is reacted with 43ml 30% hydrogen peroxide solution to prepare polyperoxytungstic acid solution;

[0026] (2) Preparation of polyperoxytungstic acid composite sol with added surfactant: Weigh 4.5g of F127 (average molecular weight is 12600) and dissolve it in absolute ethanol, add to the prepared in (1) containing W 6+ 0.008mol polytungstic acid polyperoxide solution, and reflux at 90°C for one and a half hours, and finally obtain a slightly viscous dark blue composite sol;

[0027] (3) WO 3 Preparation of nanocrystals: the composite sol prepared in (2) is poured into Al 2 o 3 In the crucible, it is annealed and calcined at 500°C in a muffle furnace to completely burn off the organic matter, and finally the light yellow-green WO 3 nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com