Optical glass bubbler

A technology of optical glass and bubbler, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems that affect the internal quality of optical glass and is not suitable for optical glass production, and achieve faster melting efficiency and uniform glass color Consistent, color-suppressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

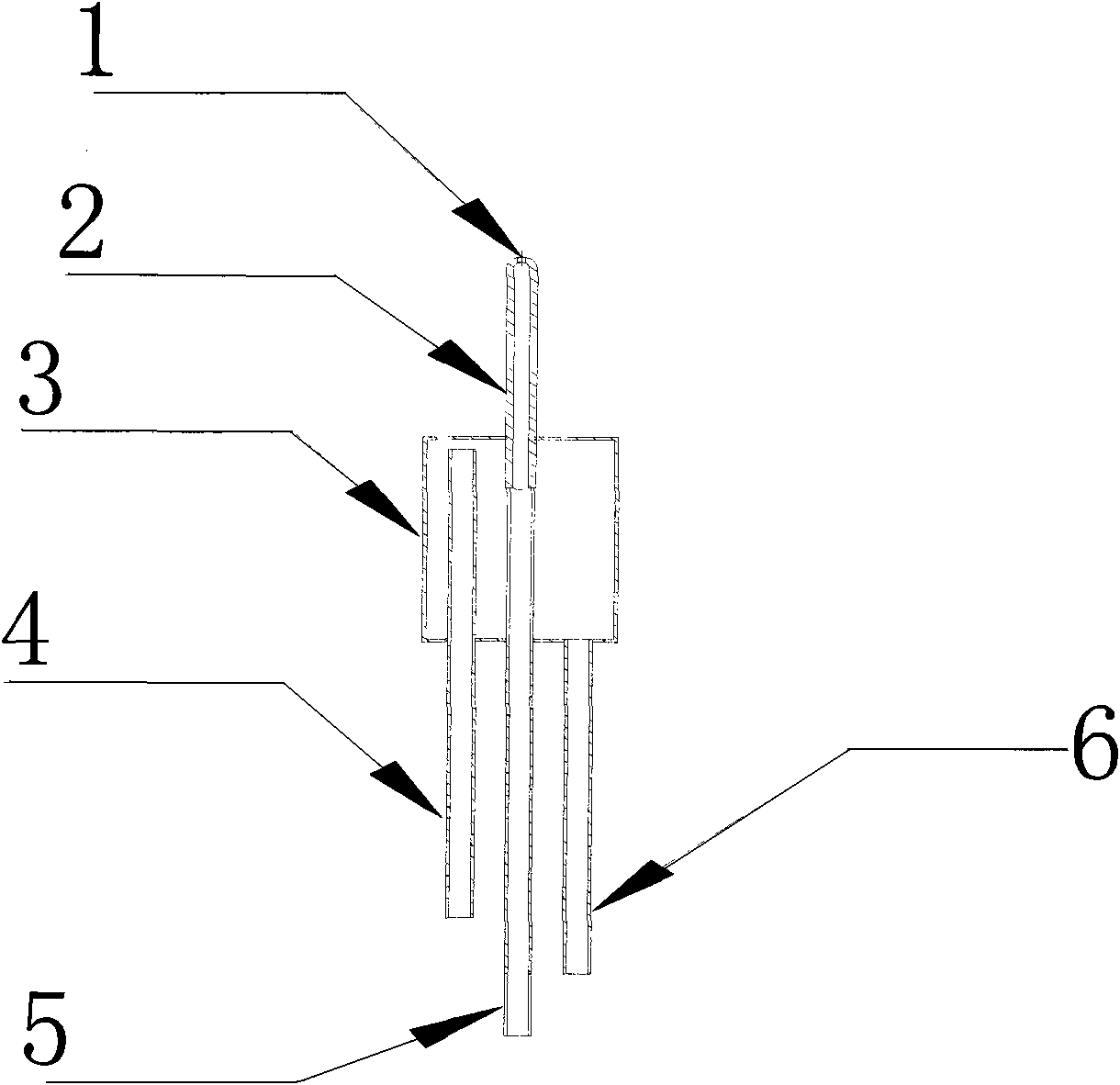

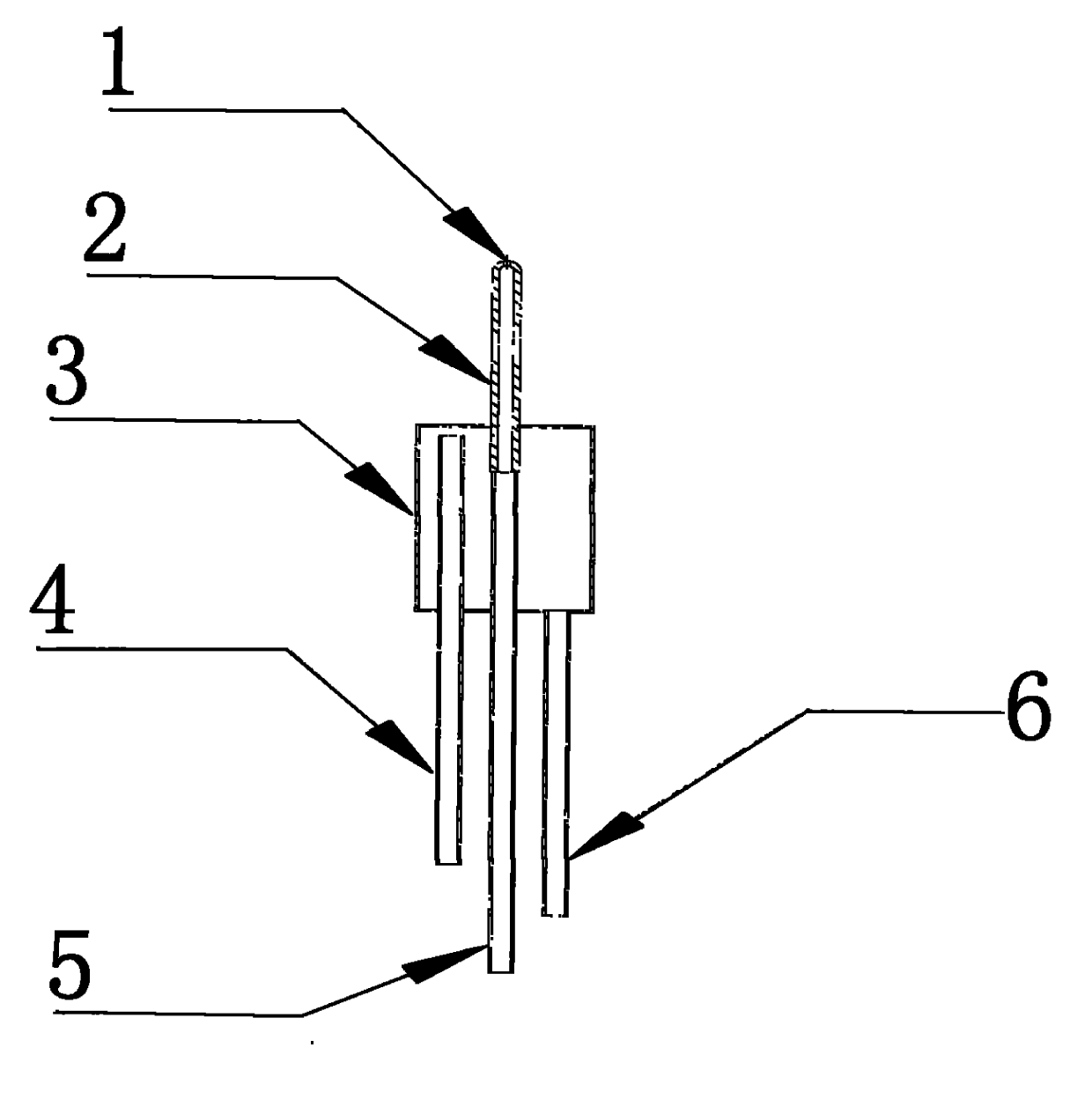

[0011] Such as figure 1 shown. The optical glass bubbler is composed of an air outlet 1, an air outlet pipe 2, a cooler 3, a water outlet pipe 4, an air inlet pipe 5 and a water inlet pipe 6. The air inlet pipe 5 is welded together with the air outlet pipe 2 to form a channel for compressed air. The cooler 3 is coaxial with the air outlet pipe 2, the air outlet pipe 2 passes through the cooler 3, and the seams are welded. The cooler 3 forms a closed circulating water space, and the water outlet pipe 4 and the water inlet pipe 6 are welded at the lower end. The device of the invention is welded by platinum material. The device of the present invention can also be welded with palladium gold or rhodium gold materials.

[0012] Before the masonry melting pool is built, the cavity of the bubbler is reserved for the molten bottom brick. The size of the cavity must be coaxial, and the diameter of the cavity is slightly larger than the diameter of the corresponding part of the bub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com